Automatic error-preventing workpiece

An error-proofing and workpiece technology, applied in vehicle parts, manufacturing tools, metal processing, etc., can solve problems such as inability to install at will, poor use effect, and inability to automatically alarm, and achieve the effects of low production cost, convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

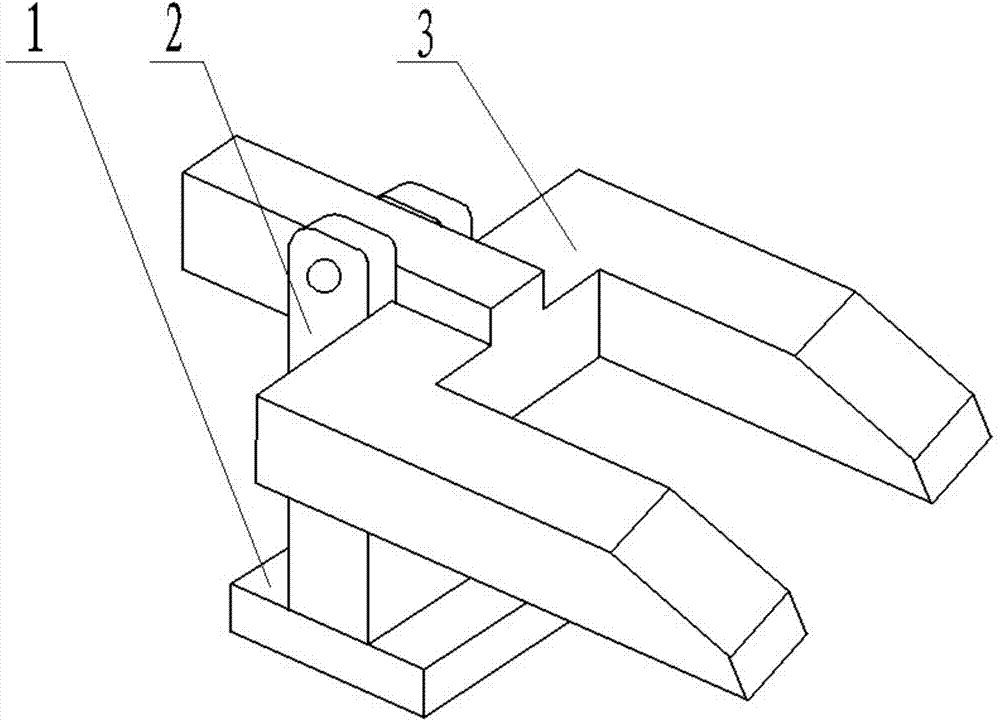

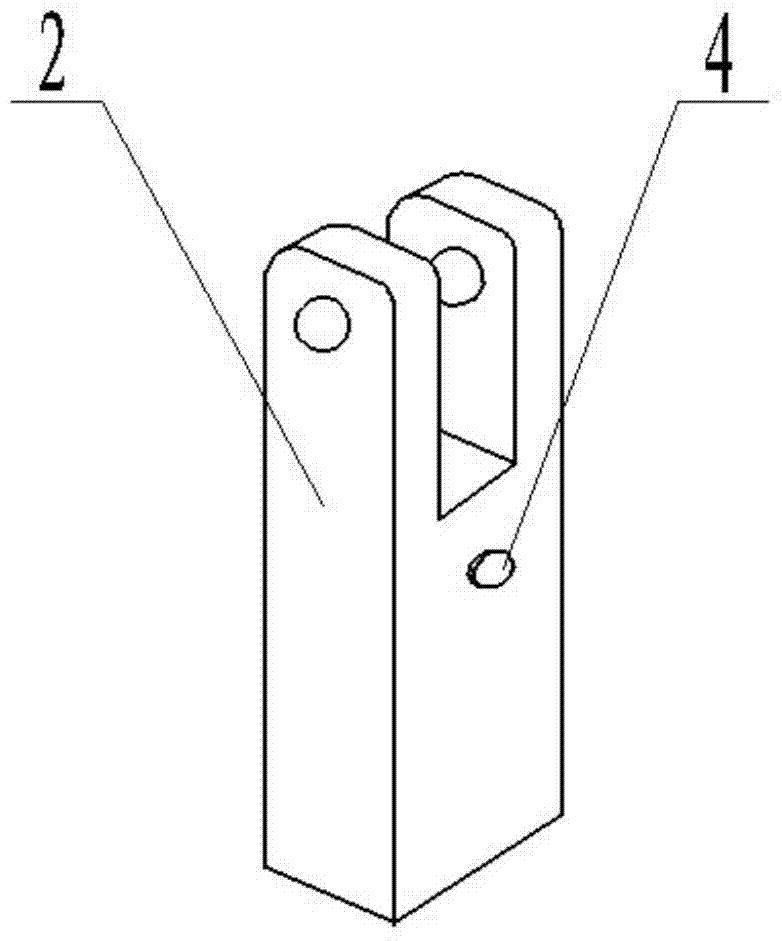

[0022] Such as figure 1 As shown, an automatic error-proofing workpiece, wherein: includes positioning claw 3, support frame 2, pin shaft, alarm device and base 1; described positioning claw 3 is installed and fixed on the support frame 2 using a pin shaft, and the support frame 2 is installed and fixed on the base 1; the support frame 2 is provided with an alarm device.

[0023] The base 1 is provided with a clamping device, which can be clamped and fixed on the workbench.

[0024] The alarm device described above includes an audible and visual alarm and a micro switch.

Embodiment 2

[0026] Such as figure 1 as shown in figure 1 As shown, an automatic error-proofing workpiece, wherein: includes positioning claw 3, support frame 2, pin shaft, alarm device and base 1; described positioning claw 3 is installed and fixed on the support frame 2 using a pin shaft, and the support frame 2 is installed and fixed on the base 1; the support frame 2 is provided with an alarm device.

[0027] Described base 1 is set as electromagnet, and electromagnet can be fixed on the workbench.

[0028] The alarm device includes an audible and visual alarm and a micro switch.

[0029] When working, first install the automatic error-proofing workpiece on the position where positioning and error-proofing is required, fix the automatic error-proofing workpiece on the workbench through the base, then lift the positioning claw, and then place the exhaust flange on the workbench for guidance position, and then press down the positioning claw, if the positioning claw pressure cannot re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com