Parallel robot fixing plate

A technology of robots and fixing plates, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as lack of calibration conditions, increased maintenance costs, accidental machine damage, etc., to achieve scientific and reasonable structure, improve fixing performance, and simple and reliable installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

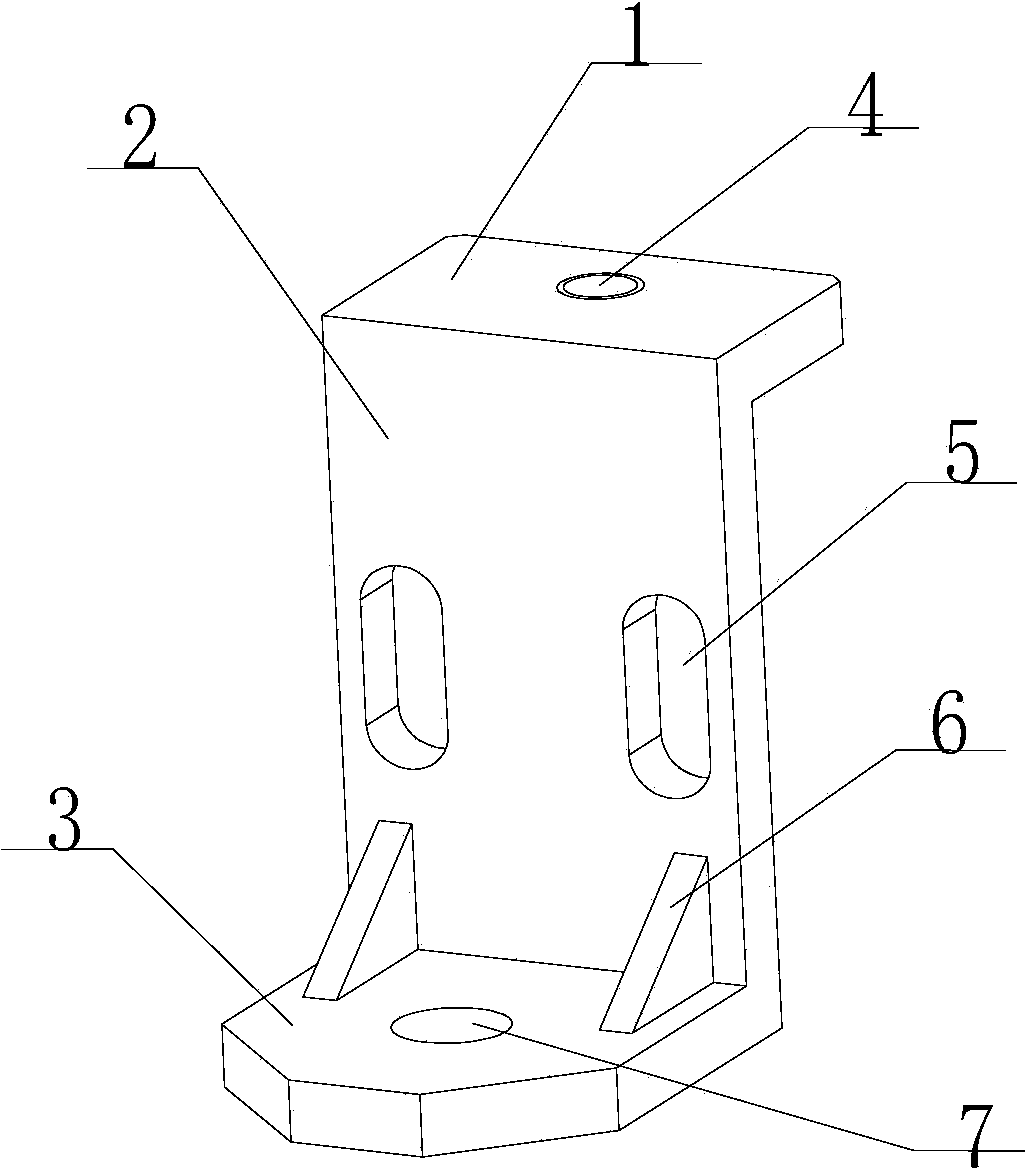

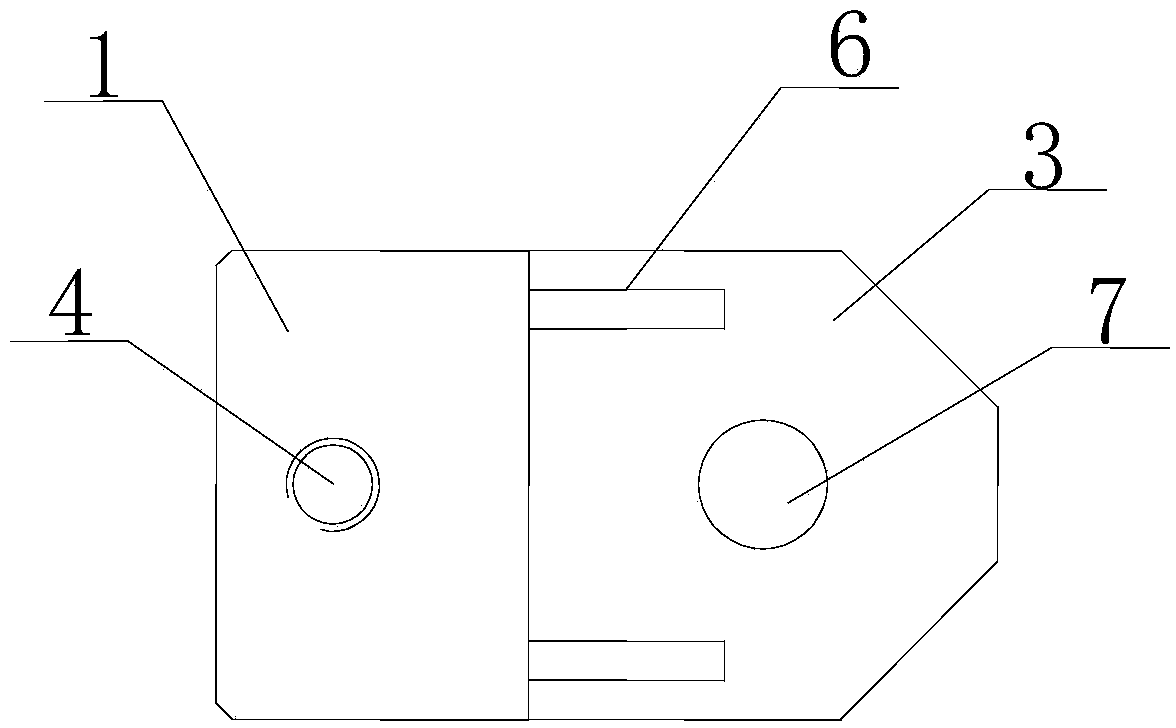

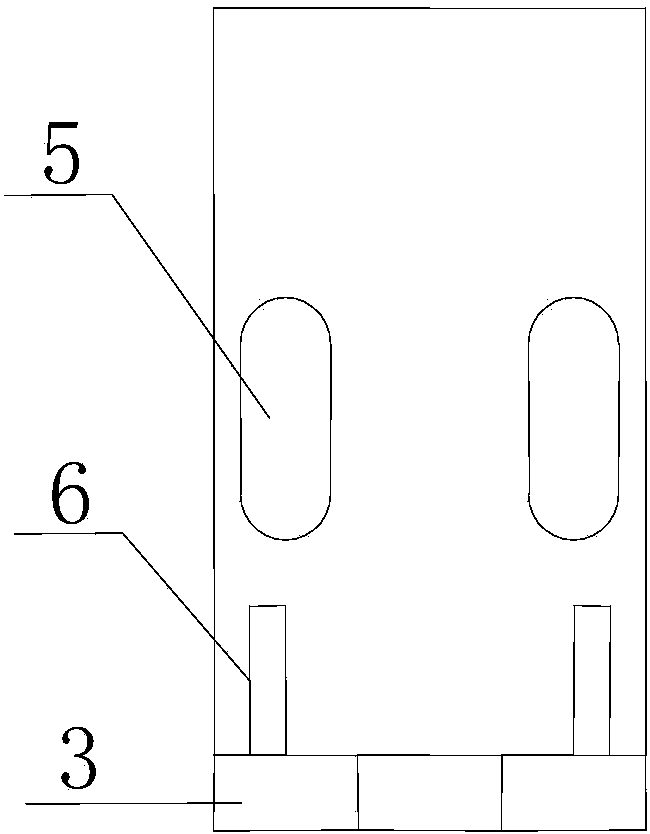

[0028] to combine figure 1 Describe this embodiment, a fixed plate for a parallel robot, including a horizontal plate 1, a vertical plate 2, a bottom plate 3, and a rib plate 6. It is characterized in that five plates are formed by welding, and the horizontal plate 1 and the bottom plate 3 are arranged horizontally. The vertical plate 2 is arranged vertically, and the overall structure is Z-shaped. The horizontal plate 1 is provided with threaded holes 4, the vertical plate 2 is provided with two elongated holes 5, and the bottom plate 3 is provided with Through hole 7.

[0029] An angle of 90 degrees is formed between the horizontal plate 1 and the vertical plate 2, and between the vertical plate 2 and the bottom plate 3.

[0030] The threaded hole 4 is set at the center of the horizontal plate 1 .

[0031] The elongated holes 5 are arranged symmetrically along both sides of the centerline of the riser 2 .

[0032] The ribs 6 are two triangular plates, and the two right-an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com