Gloss oil forming and coating transfer-printing device and transfer-printing process thereof

A varnish and coating technology, used in rotary printing machines, rotary printing machines, gravure rotary printing machines, etc., can solve the problem of inability to transfer optical imaging media, inability to achieve optical effects and texture effects, and single visual effects of substrates, etc. problems, to achieve the effect of reducing equipment length, saving space and cost, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

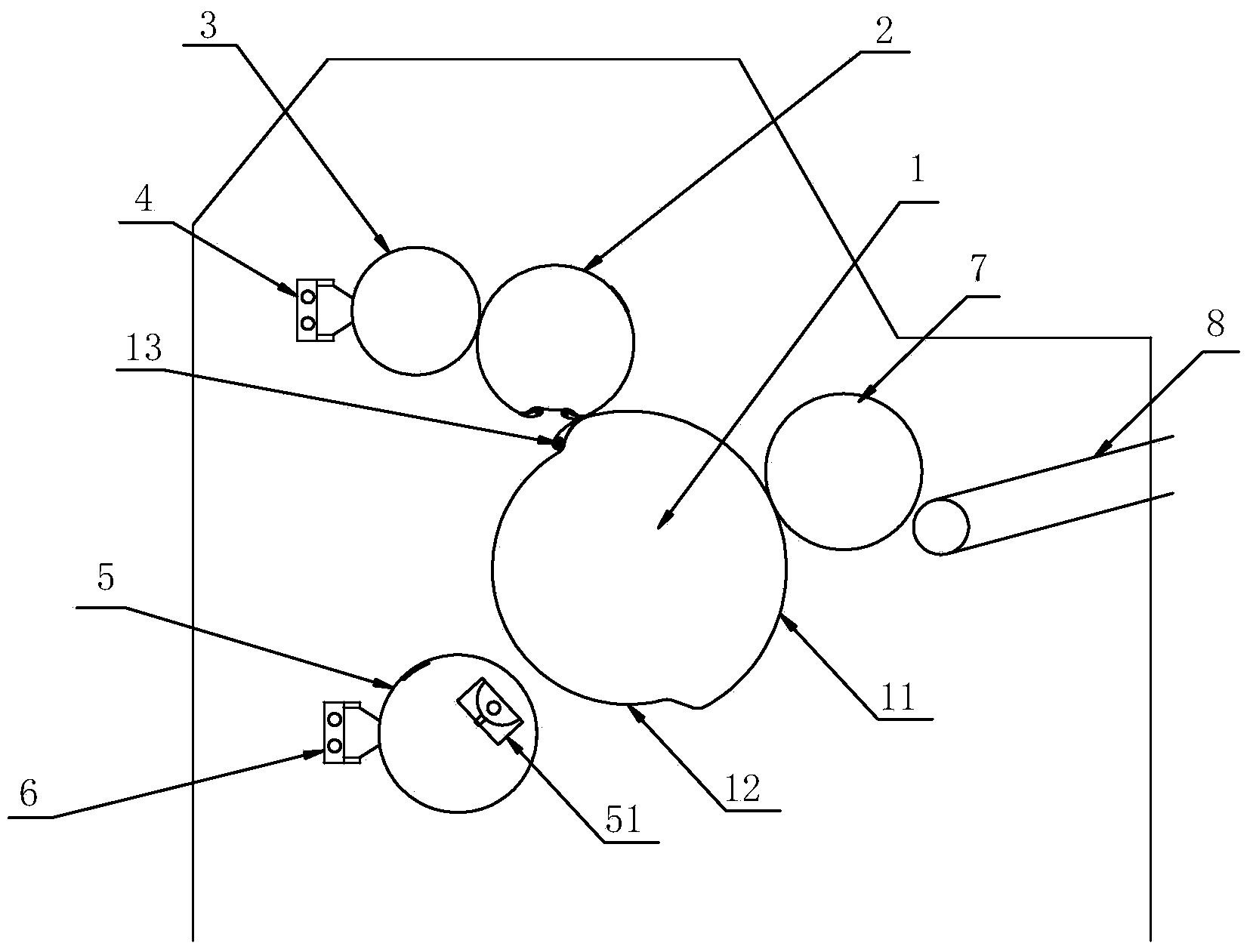

[0020] Such as figure 1 As shown, the varnish forming coating transfer device of the present invention includes an embossing cylinder 1, a printing plate cylinder 2, a coating cylinder 3, a first coating scraper 4, a forming transfer roller 5 and The second coating scraper 6; wherein, the printing plate cylinder 2 and the forming transfer printing roller 5 are arranged in a satellite pattern on the periphery of the embossing cylinder 1; the printing plate cylinder 2 and the coating cylinder 3 are circumscribed , the first coating scraper 4 is in contact with the coating roller 3 ; the second coating scraper 6 is in contact with the forming transfer roller 5 . The embossing cylinder 1 has a working semicircle 11 and an intermittent semicircle 12, the radius of the intermittent semicircle 12 is smaller than the working semicircle 11, and one of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com