Intelligent high-speed film edge sealing machine

A high-speed, thin-film technology, applied in packaging, conveyor belt wrapping, wrapping paper shrinkage, etc., can solve problems such as single function, high cost, and low efficiency, and achieve the effect of expanding demand, unique action, and avoiding mutual constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

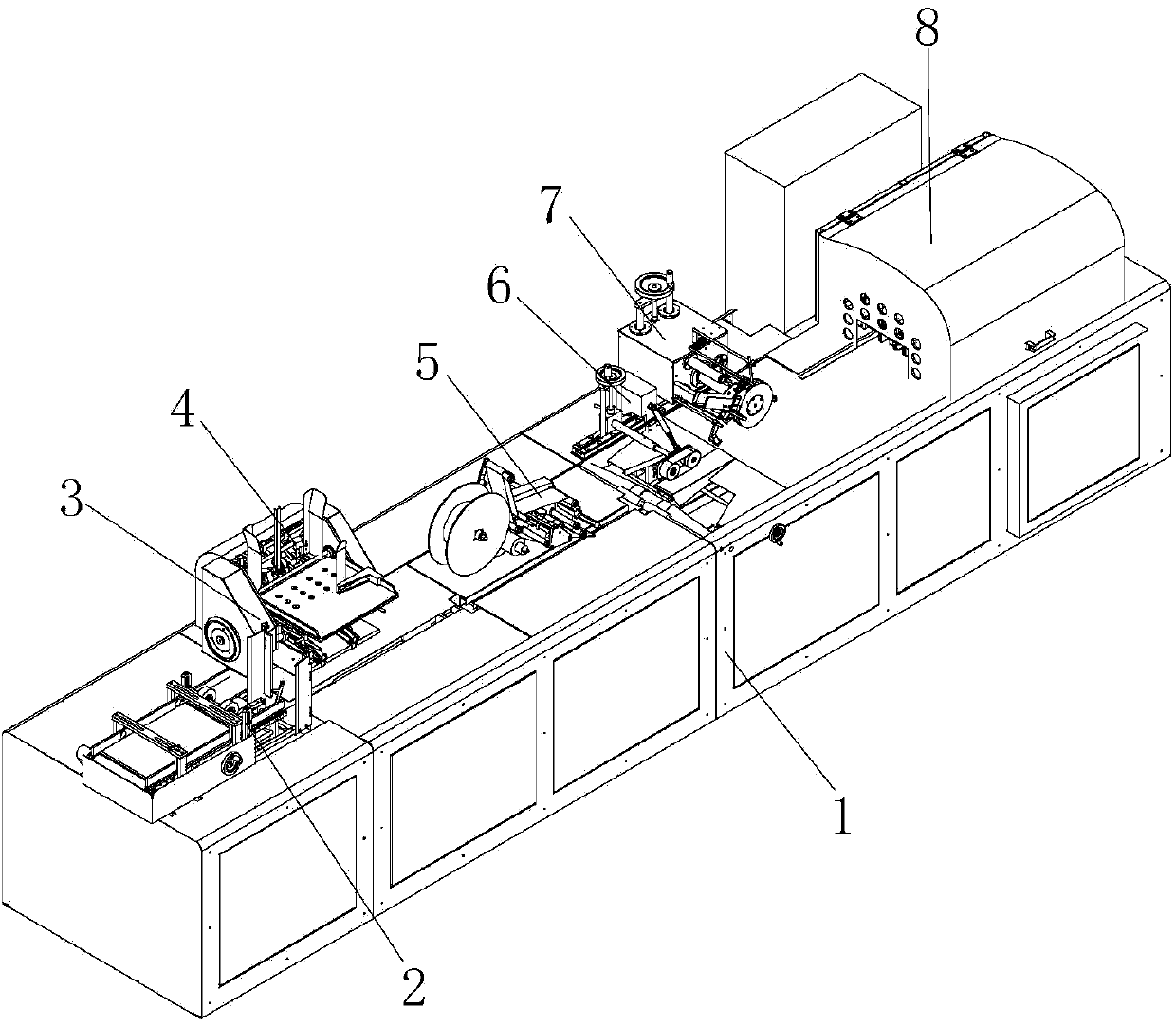

[0015] See Figures 1 to 4 As shown: the present invention includes a frame body 1, a single-page rule separation mechanism 2, a page-turning mechanism 3, a single-page separation and delivery mechanism 4, a labeling mechanism 5, a code spraying mechanism 6, a card separating mechanism 7, and a sealing mechanism 8. Its characteristics That is: the frame body 1 is provided with a single rule separation mechanism 2, a flipping mechanism 3, a single page separation and delivery mechanism 4, a labeling mechanism 5, a coding mechanism 6, a card separating mechanism 7, and a sealing mechanism 8 from one end to the other end. .

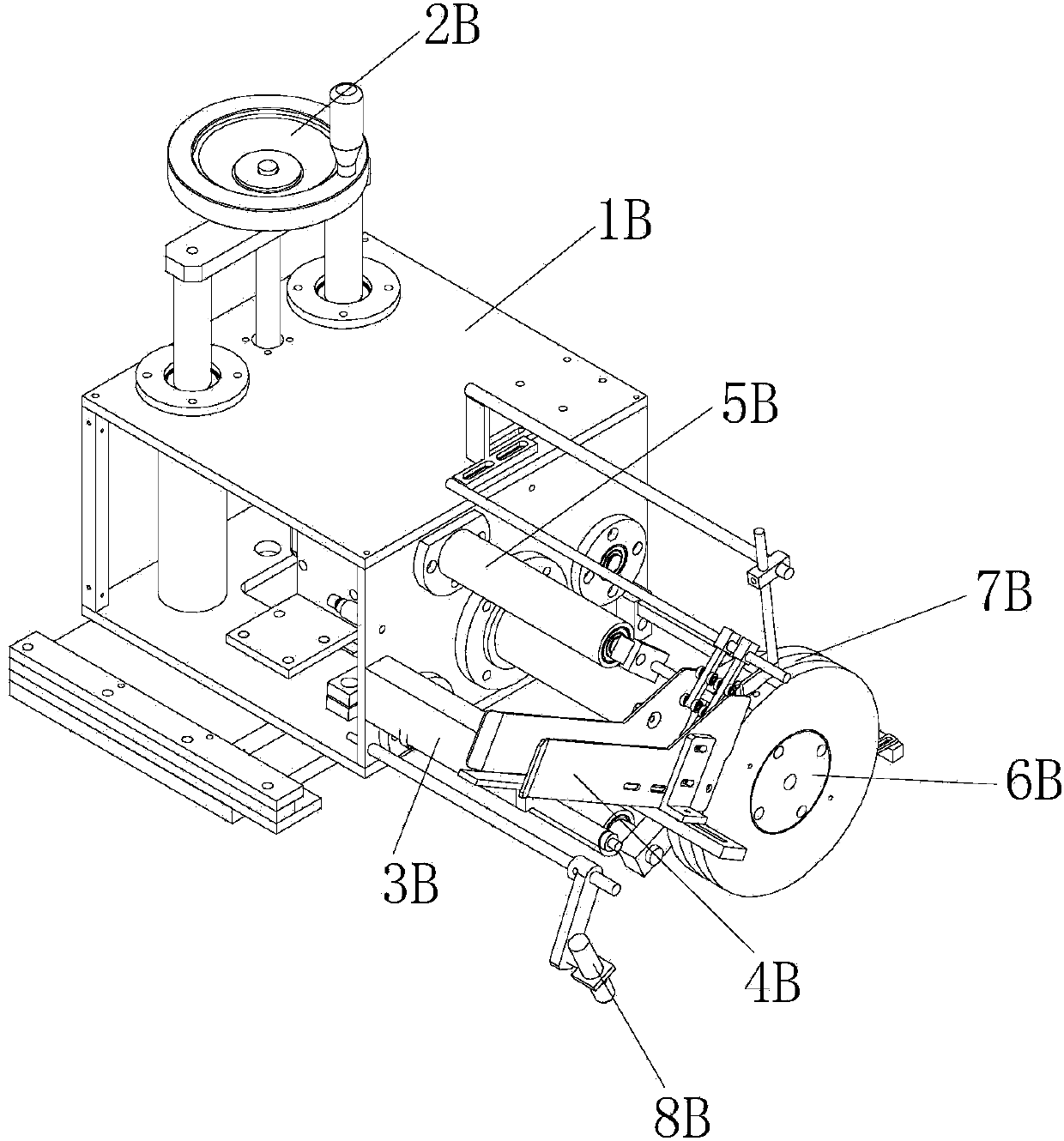

[0016] The sealing mechanism 8 includes a longitudinal sealing mechanism and an end sealing mechanism.

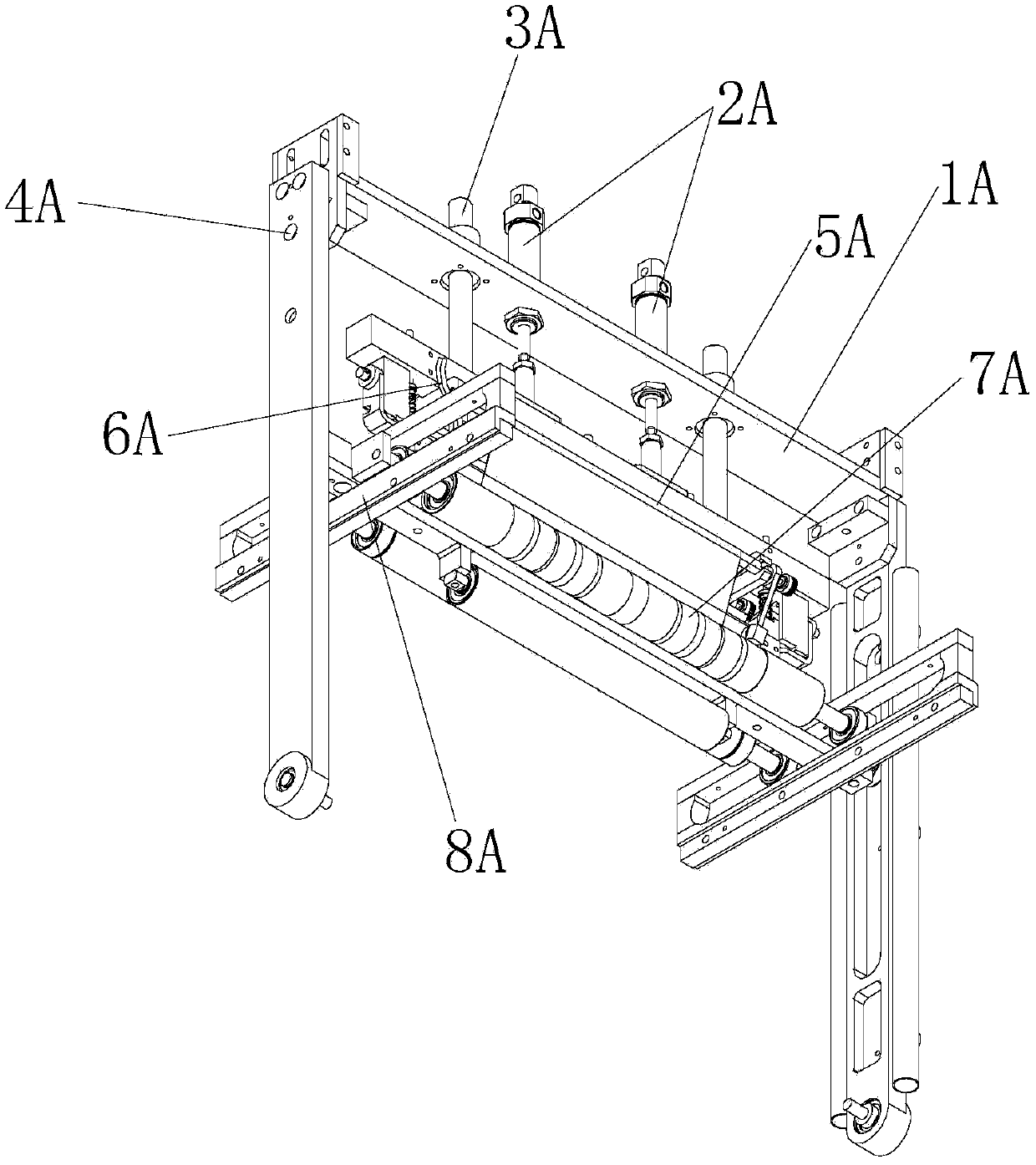

[0017] Described sealing mechanism 8 comprises crossbeam 1, lifting knife cylinder 2, upper sealing knife 5, lower knife seat 7, and crossbeam 1 is provided with lifting knife cylinder 2, guide shaft 3, and the lower end of lifting knife cylinder 2, guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com