Cheese Dyeing Machine

A dyeing machine and package yarn technology, applied in the field of dyeing and finishing machinery, can solve the problems of increased cylinder body pressure requirements, increased production costs, and high water consumption, and achieve the effects of reduced energy consumption, cost savings, and reduced water consumption of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Below by embodiment, the present invention is further elaborated:

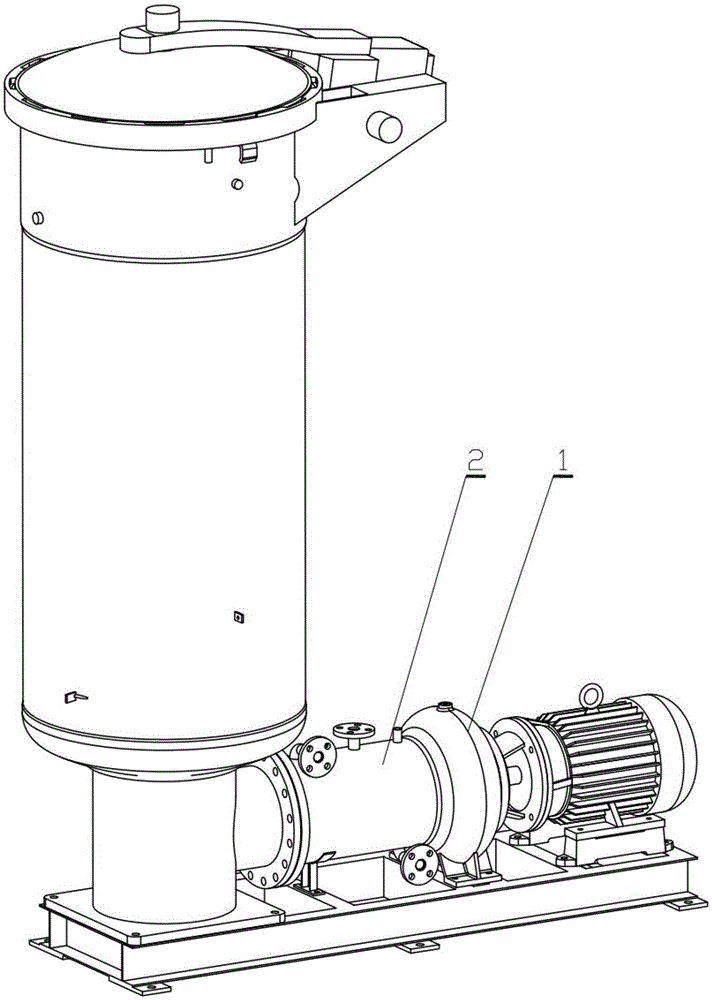

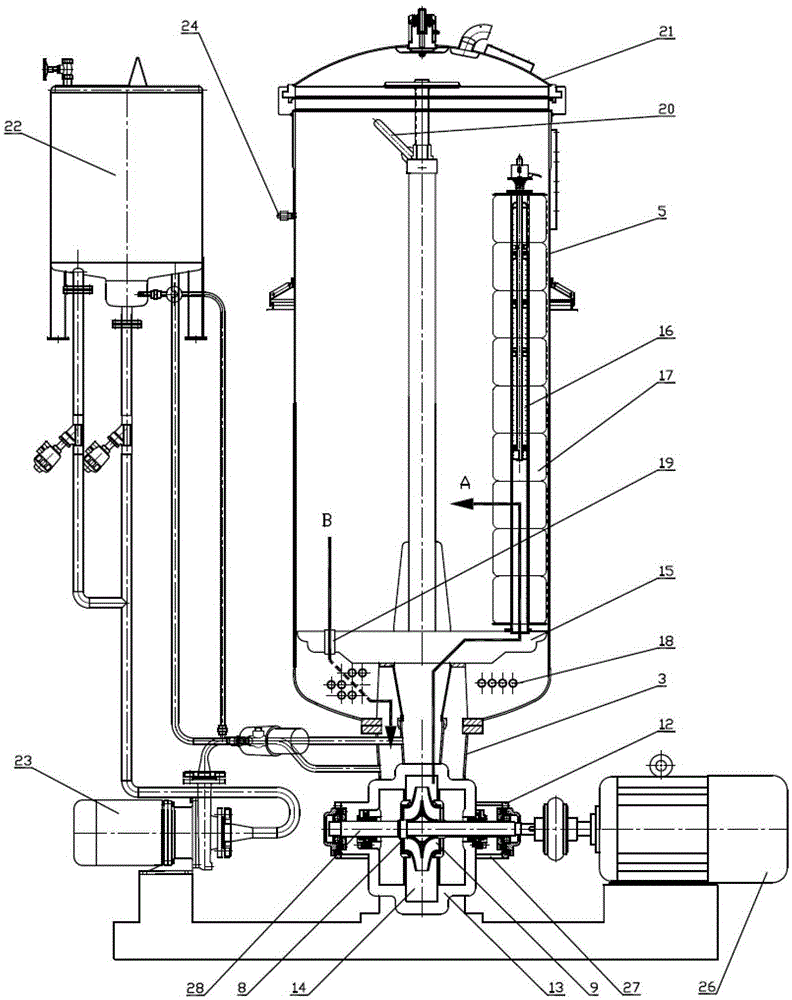

[0079] like figure 2 As shown, this embodiment provides a cheese dyeing machine, which includes a main cylinder, a creel, a centrifugal pump, and a heat exchange coil (18). The creel is fixed in the dye vat, and the yarn bamboo on the creel is hollow. , communicate with the main pump outlet. The heat exchange coil (18) is located at the bottom of the main cylinder, and is connected to the water source and the steam source, and the centrifugal pump is installed in the support frame at the bottom of the cylinder body of the dyeing machine.

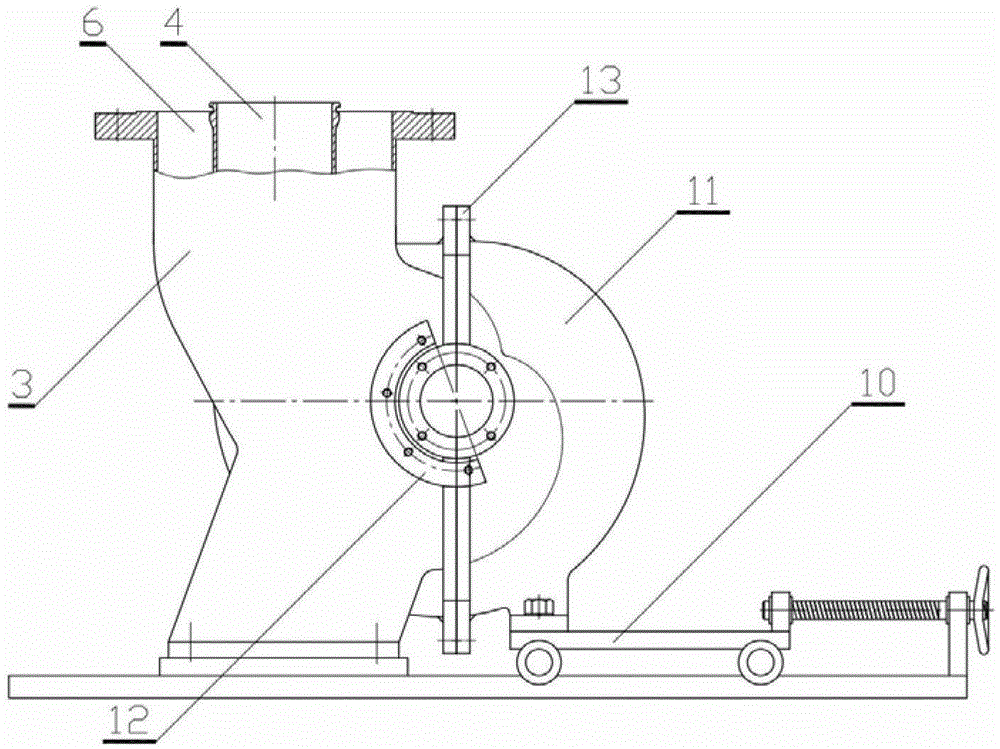

[0080] figure 2 The side view of the bottom of the cylinder body of this embodiment is shown. The centrifugal pump outlet (4) is connected to the outlet of the centrifugal pump in the bottom of the cylinder body, so that the dye liquor can be transported from the centrifugal pump outlet to the cylinder body (5) through the centrifugal pump outlet.

[0081] The ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com