Square extending type cloth conveying tube

A square cloth feeding technology, applied in the field of dyeing and finishing machinery, can solve the problems of low passing speed, slow water circulation speed, slow water cloth separation, etc., and achieve the effect of lowering the water level of the machine, reducing the dyeing cost, and reducing the dyeing bath ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

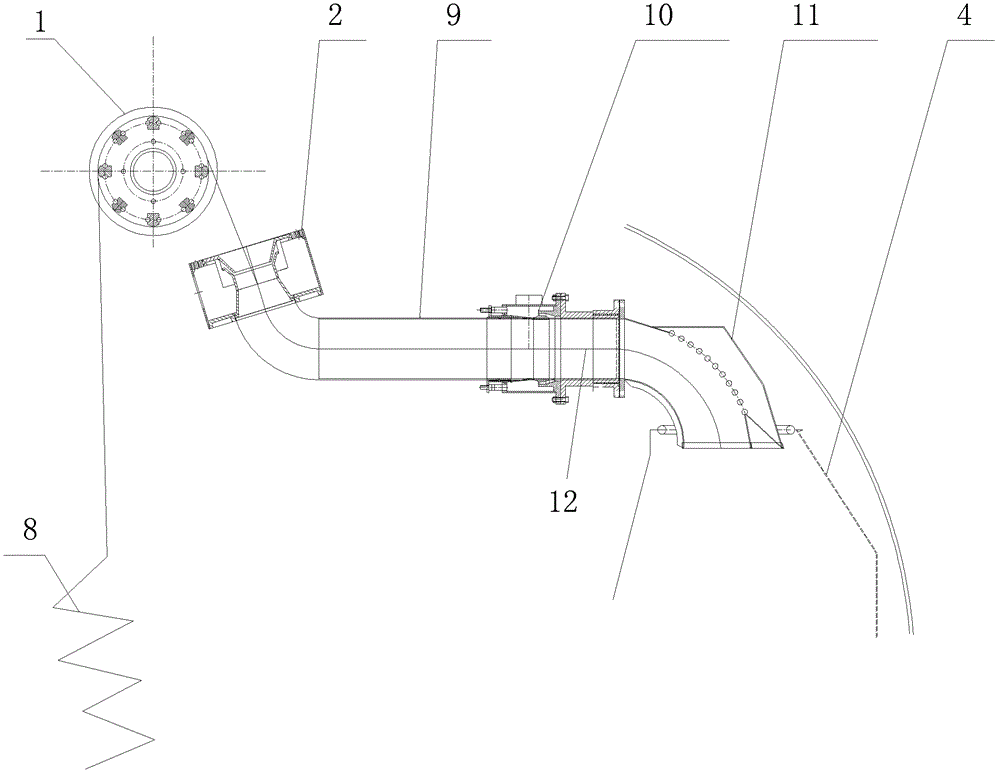

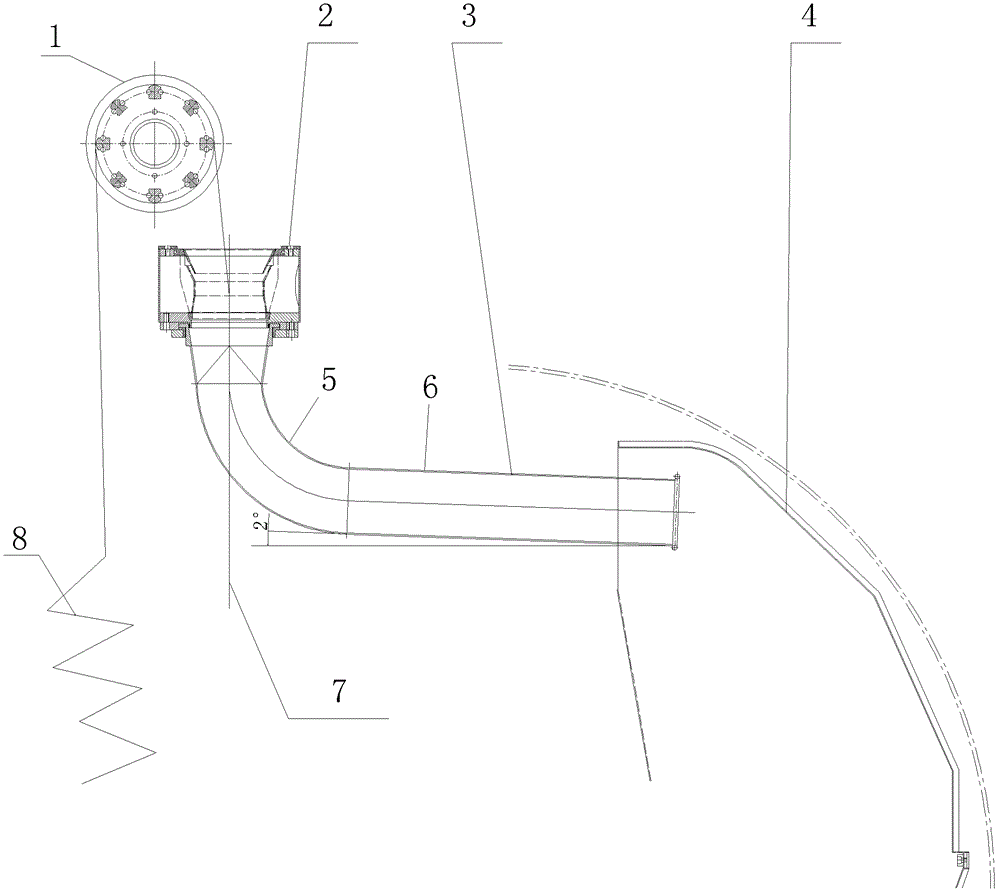

[0028] like figure 2 The UF and UFH machines shown are square stretch-type cloth feeding pipes, including a lifting roller, a front nozzle, a square cloth feeding pipe and a rear water diversion plate. The lifting roller is located above the front nozzle side, and the front nozzle is placed horizontally. section and straight section, the curved section is swingably connected to the lower end of the front nozzle, the straight section is placed obliquely, and the outlet of the square distribution pipe faces the rear water diversion plate.

[0029] The swing axis of the square feeding pipe is the central axis of the front nozzle. The swing angle of the square feeding pipe is 10°. The straight section forms an angle of 2° with the horizontal plane. The entrance at the upper end of the curved section is a structure below the upper circle. One side of the rear water dive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com