Collar cloth dyeing machine

A dyeing machine and collar technology, applied in the field of dyeing and finishing machinery, can solve the problems of increasing the difficulty of collar cloth finishing, local color difference, and easy creases, etc., to achieve good dyeing effect, less creases, and better dyeing bath ratio low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

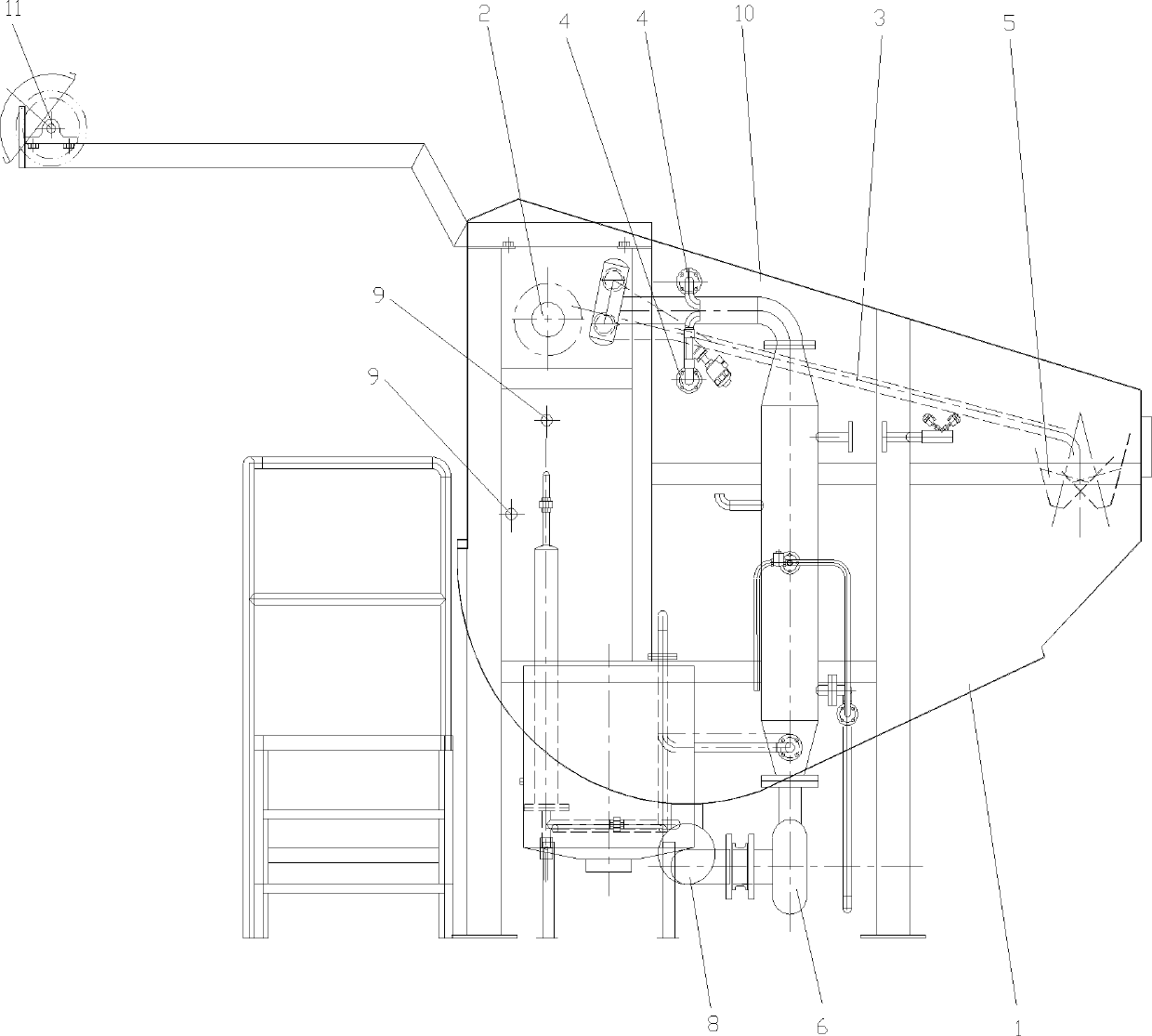

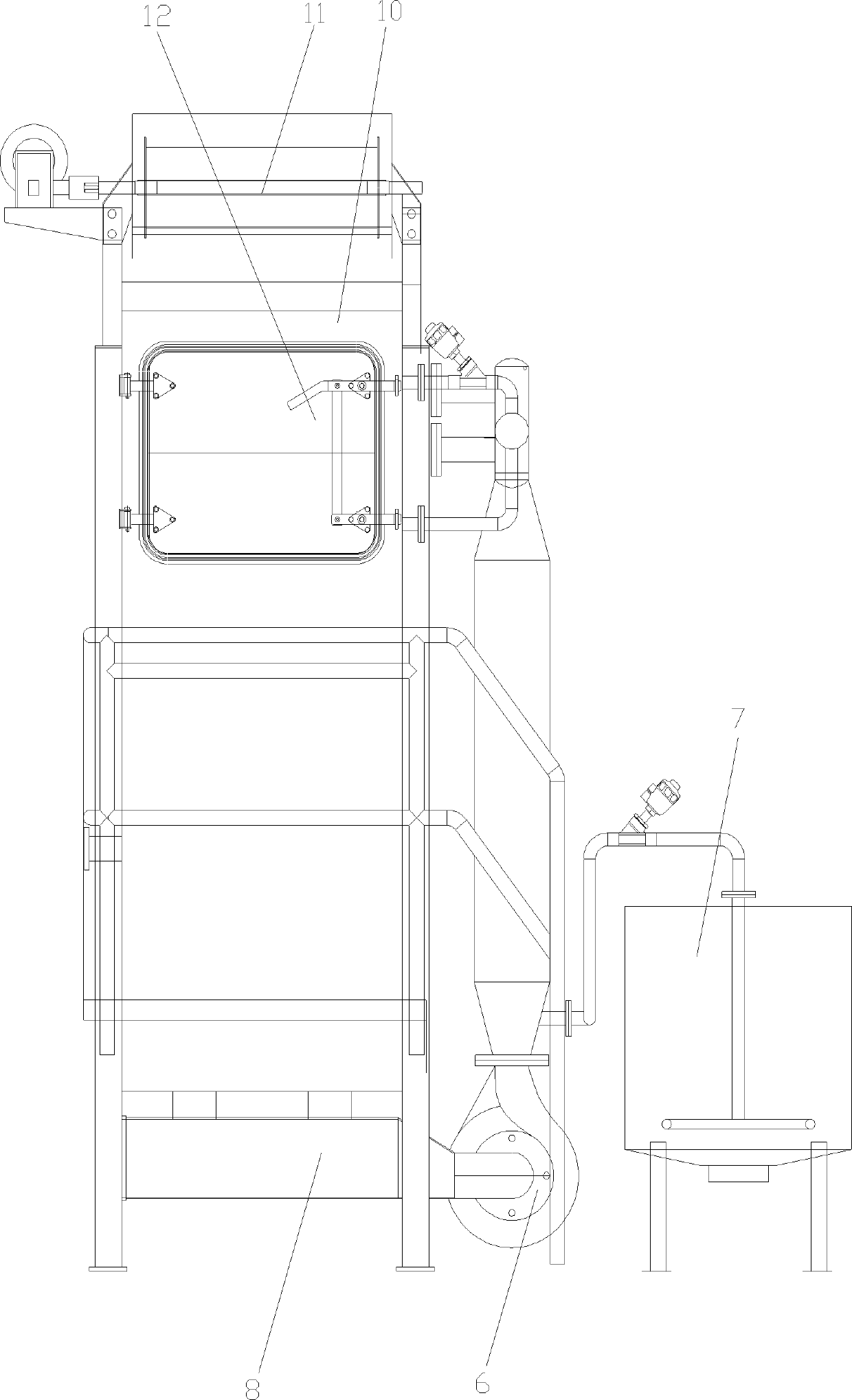

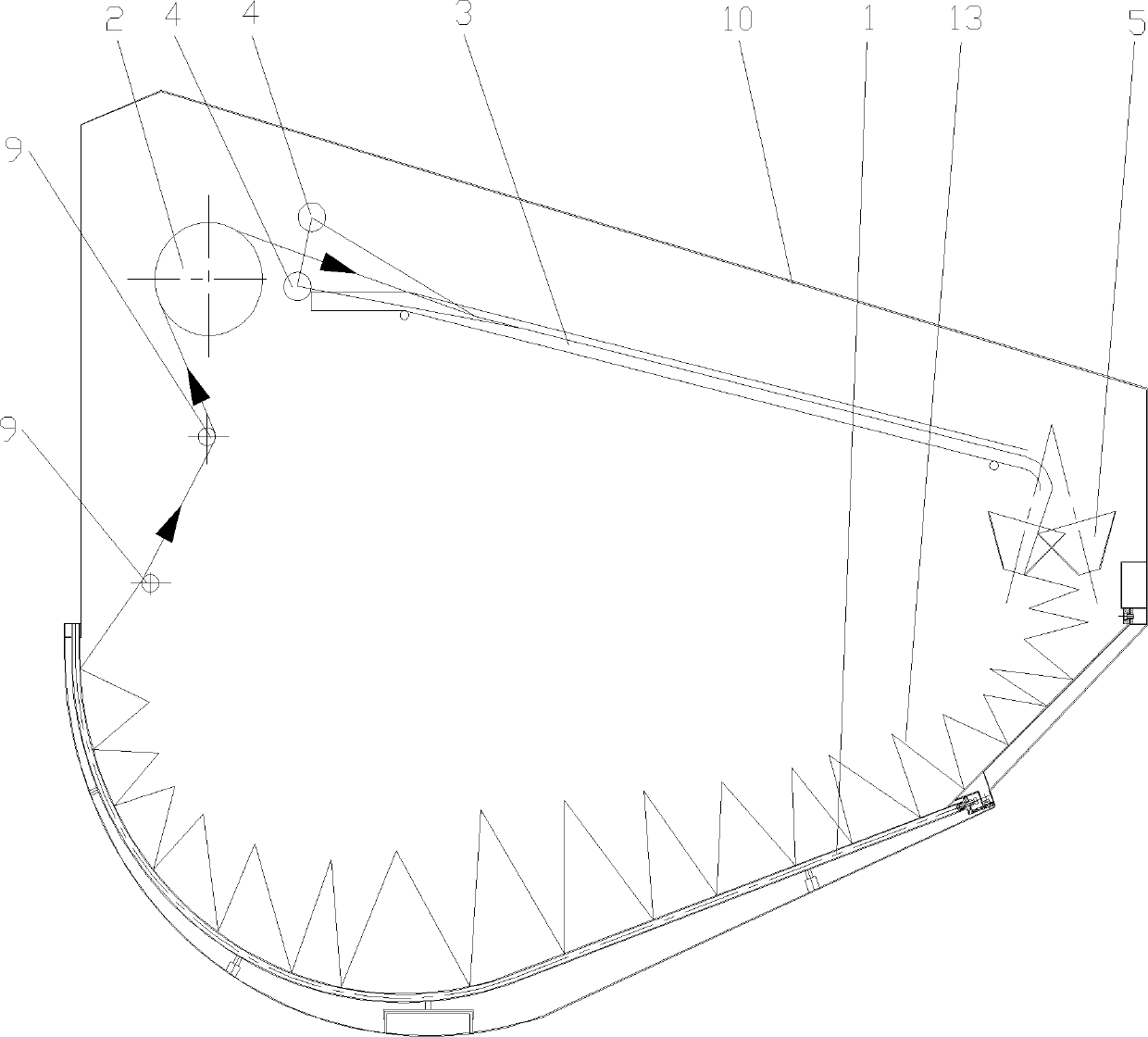

[0023] Figure 1 to Figure 3 The shown collar cloth dyeing machine includes: dyeing tank 1, lifting roller 2, sliding cloth device 3, nozzle device, swing device, circulation pump 6, dye barrel 7, filter 8, cloth guide roller 9, shell 10 and Out of cloth roller 11.

[0024] Wherein, the dyeing tank 1 is a concave structure, and the end near the head is lower than the end near the tail. The lifting roller 2 is driven by a motor, which plays a role in promoting and guiding the collar cloth 13 to move forward. The sliding cloth device 3 is two plates arranged in parallel. The nozzle device includes nozzles 4 and related hydraulic pipelines, the nozzles 4 are arranged on the front and back of the collar cloth in pairs, and the nozzles 4 spray toward the collar cloth. The left and right arrangement includes a left and right bucket 5 and a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com