Rock foundation upper brake bottom horizontal wide seam and filling components

A technology of wide seam and gate bottom, which is applied in the field of horizontal wide seam filling at the gate bottom on the rock foundation, can solve problems such as concrete floor constraints, and achieve the effects of avoiding cracks, high construction efficiency, and reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

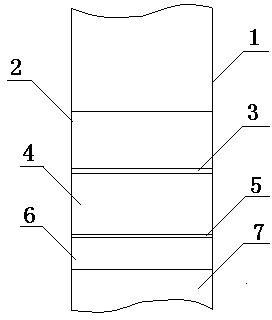

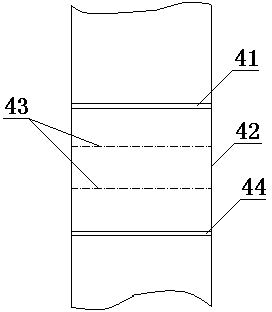

[0008] Referring to the accompanying drawings, a horizontal wide joint and filling component of the upper gate bottom on the rock foundation is characterized in that the upper gate bottom on the rock foundation is composed of the bottom bedrock 7, the concrete leveling layer 6, the wide joint 4, the interface agent 5, and the gate bottom plate 2. A layer of concrete leveling layer 6 is laid on the rock foundation 7 at the bottom, and a layer of interface agent 5 is brushed on the concrete leveling layer 6. A wide gap 4 is set between the concrete leveling layer 6 and the gate bottom plate 2, and the composite filling member is filled in the wide gap 4 , the composite filling member is provided with a composite material 42, the composite material 42 is provided with a geogrid 43, the upper surface of the composite material 42 is provided with a rubber layer 41, the lower surface of the composite material 42 is provided with a rubber pad 44, and the composite material 42 The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com