Geared turbine machine

A transmission type and turbine technology, which is applied in the direction of gas turbine devices, machines/engines, mechanical equipment, etc., to achieve the effect of improving the use value and increasing the transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

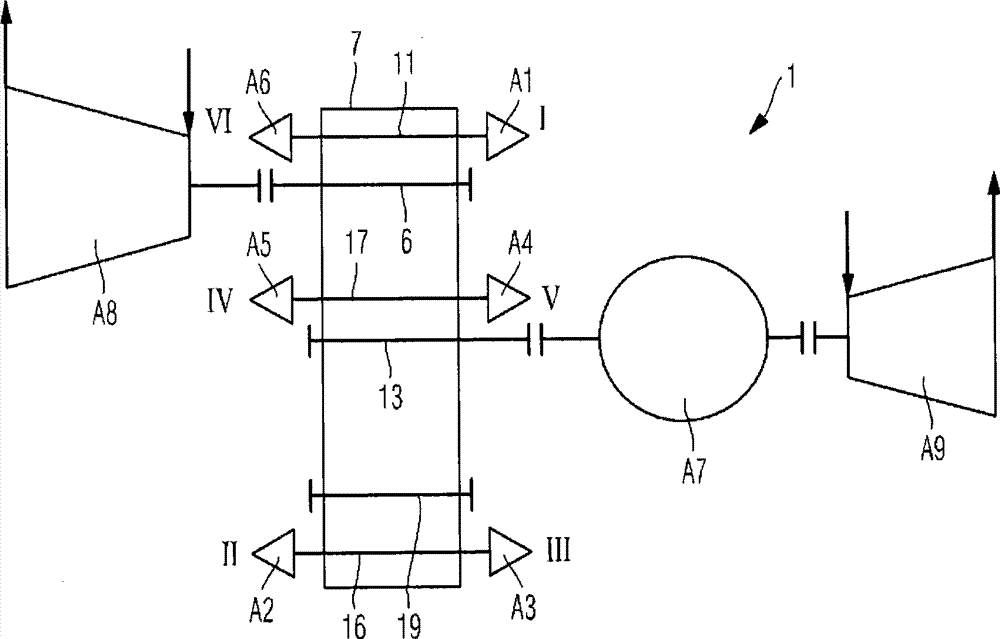

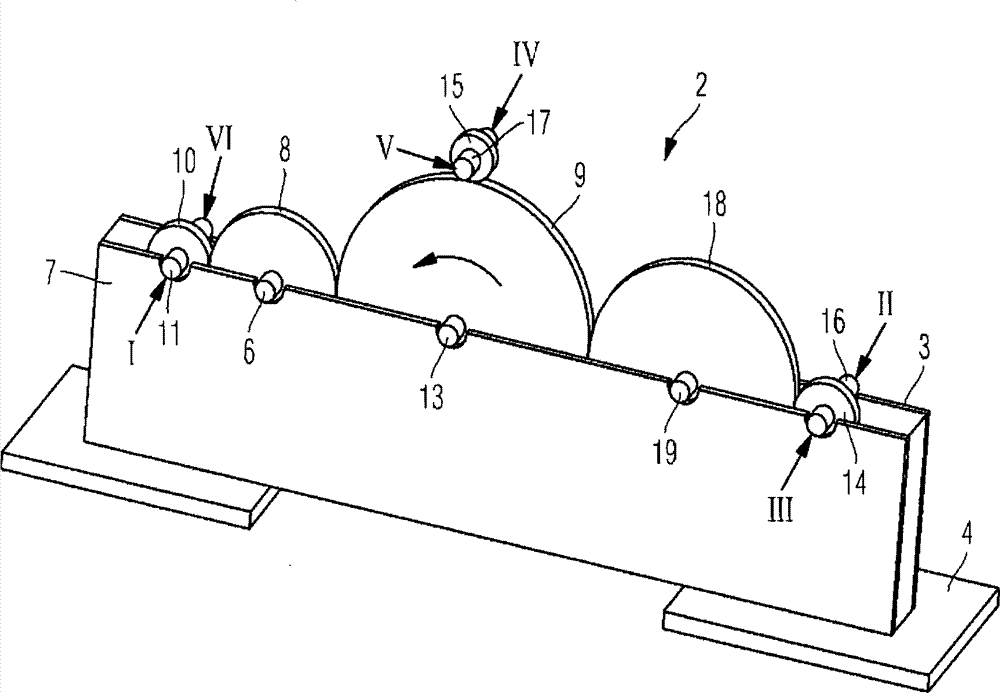

[0058] exist figure 1 The geared turbine shown in is part of a chemical plant for the treatment and reprocessing of gases. This geared turbine (1) integrates the driving and / or driven machinery (A1, A2, A3, A4, A5, A6, A7, A8, A9) into a mechanical transmission line via a transmission mechanism (2), wherein, On the one hand as drive steam turbine, gas turbine, expander and motor, and on the other hand as driven device compressor and generator.

[0059] Individual devices are coupled to each other and assembled in one or more racks (in figure 2 exemplarily shown in the frame (4)). Under the base (4) there is no figure 1 with 2 The coolers, condensers and other devices not essential to the invention but necessary for the operation of the mechanical transmission line are shown in .

[0060] Depending on the overall requirements of the process to be operated (Anforderungsprofil), the motor (A7), the steam turbine (A8) and the expander (A9) can be designed together or individ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com