Fluid conveying device

A technology of conveying device and fluid, which is applied to the components of pumping device for elastic fluid, liquid variable capacity machinery, pump control, etc. The effect of ensuring service life and working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

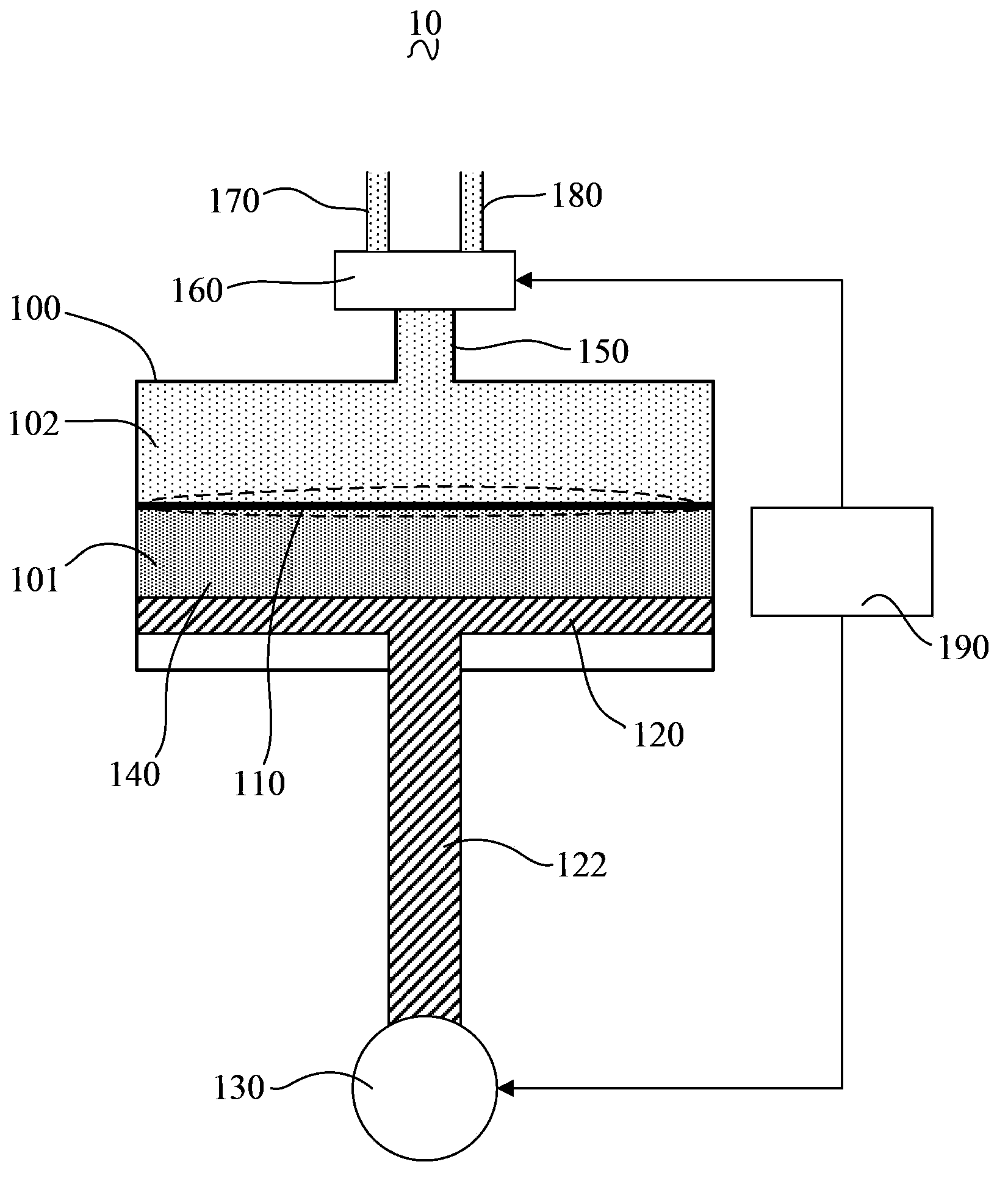

[0029] Such as figure 1 As shown, it is a schematic structural diagram of a fluid delivery device 10 according to an embodiment.

[0030] The fluid delivery device 10 includes: a cylinder 100 , an elastic film 110 , a piston 120 , a connecting rod 122 , a motor 130 , a pump oil 140 , an outlet pipe 150 , an electromagnetic valve 160 , a feed pipe 170 , a discharge pipe 180 and a controller 190 .

[0031] The elastic membrane 110 is located inside the cylinder body 100 and isolates the inner cavity of the cylinder body 100 into two independent first chambers 101 and second chambers 102 .

[0032] In this embodiment, the elastic film 110 is made of Teflon material.

[0033] The piston 120 is located in the first chamber 101 of the cylinder 100 and is in close contact with the inner wall of the first chamber 101 .

[0034] The connecting rod 122 penetrates into the first chamber 101 from the outside and is connected with the piston 120 .

[0035] The motor 130 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com