Active control method for burning instability of combustion gas turbine combustor

A technology for unstable combustion and gas turbines, which is applied to combustion methods, combustion control, and fuel supply regulation. Safe operation, clear and simple control logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

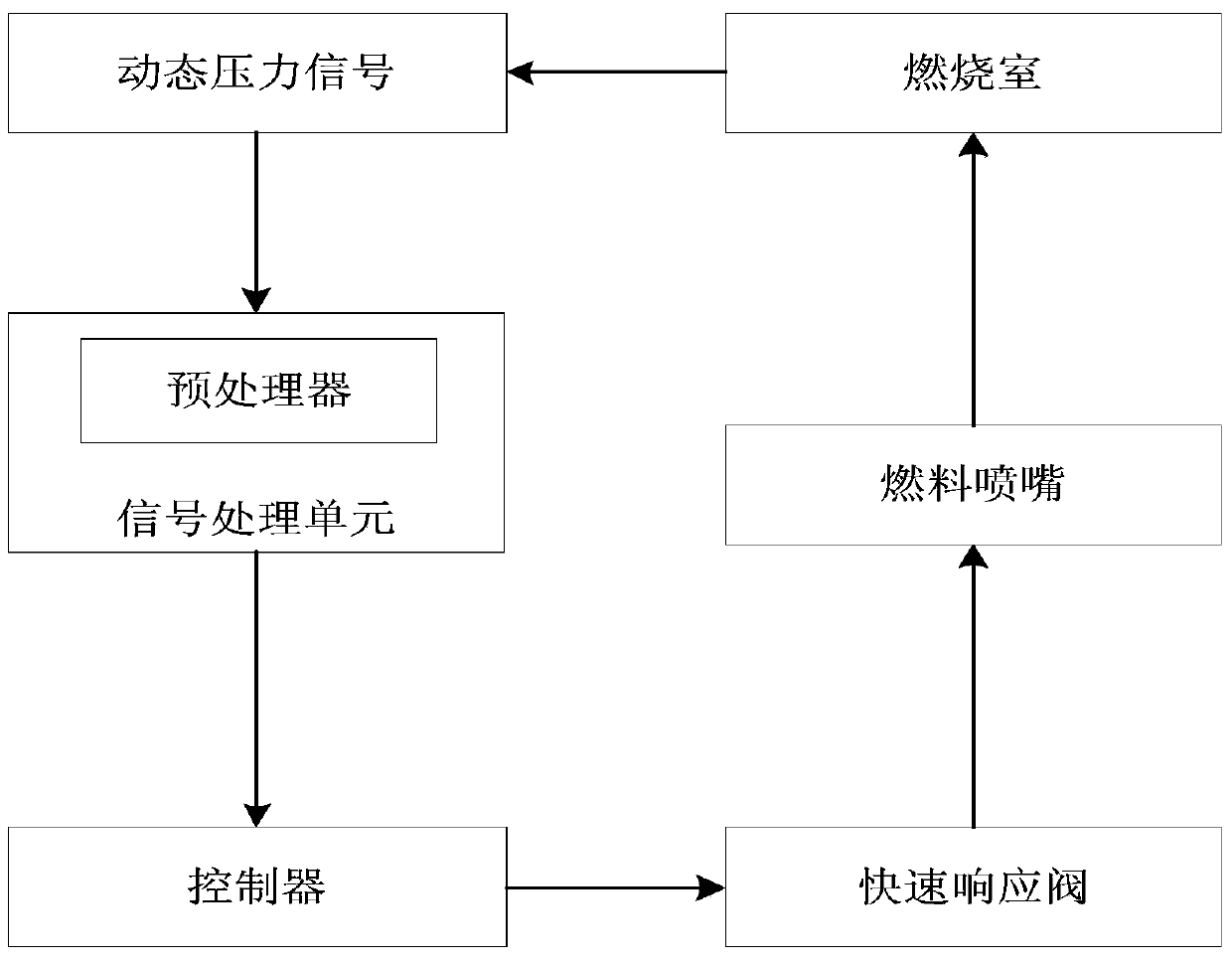

[0021] The present invention provides an active control method for combustion instability in a combustion chamber of a gas turbine, the control flow of which is as follows figure 1 As shown, the specific methods include:

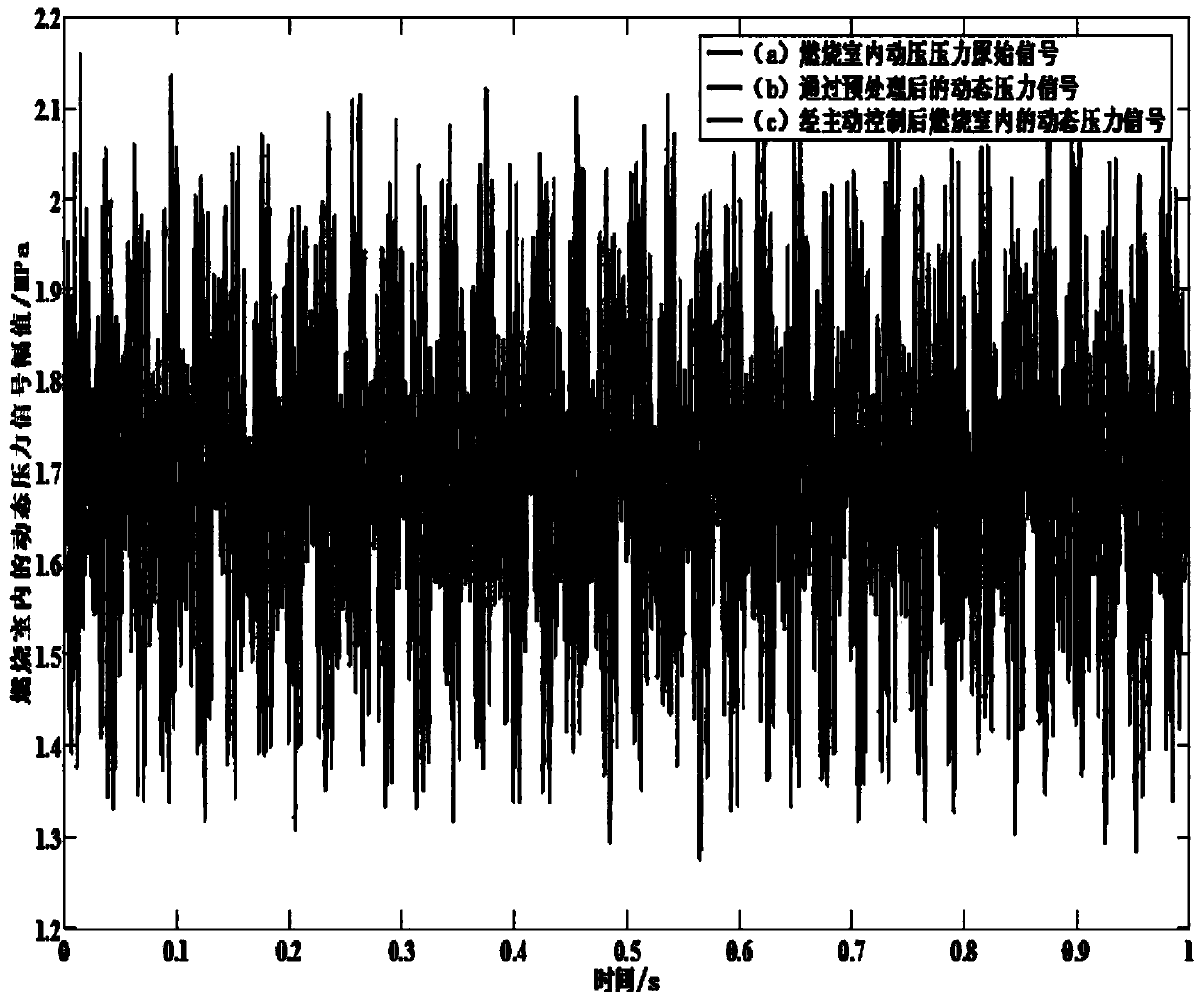

[0022] 1) Install a dynamic pressure sensor on the end cover part of the gas turbine combustion chamber or the wall of the flame tube, and the dynamic pressure sensor measures the dynamic pressure signal with a set time step t;

[0023] 2) Send the original dynamic pressure signal in the combustion chamber collected by the dynamic pressure sensor to the signal processing unit, and record the original signal as P(t), t∈[τ 1 ,τ 2 ]; τ 1 is the time to start recording data, τ 2 is the moment at which data recording ends;

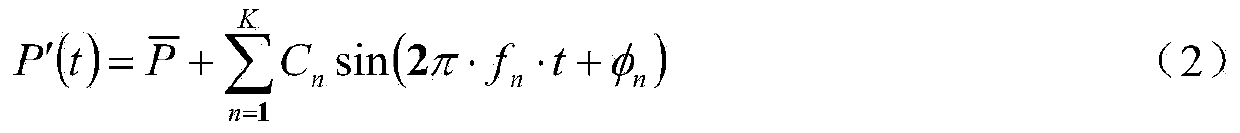

[0024] 3) The original dynamic pressure signal is denoised by the prepr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com