System for determining position of bare chip

A technology for judging systems and bare chips, applied to measuring devices, optical devices, instruments, etc., can solve problems such as low production efficiency, rising costs, and wrong designation of reference chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] One Example which actualized the form for implementing this invention is demonstrated using drawing.

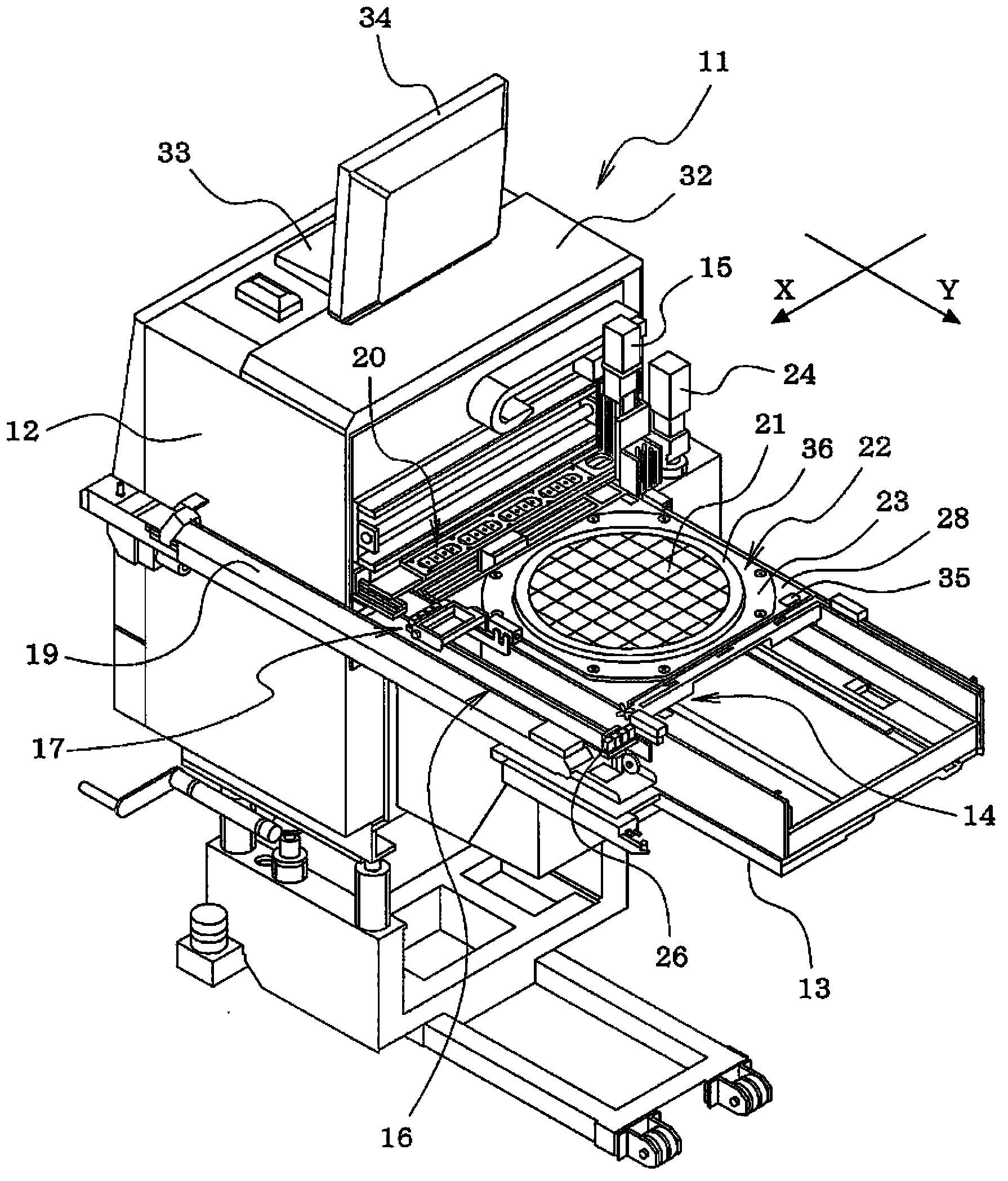

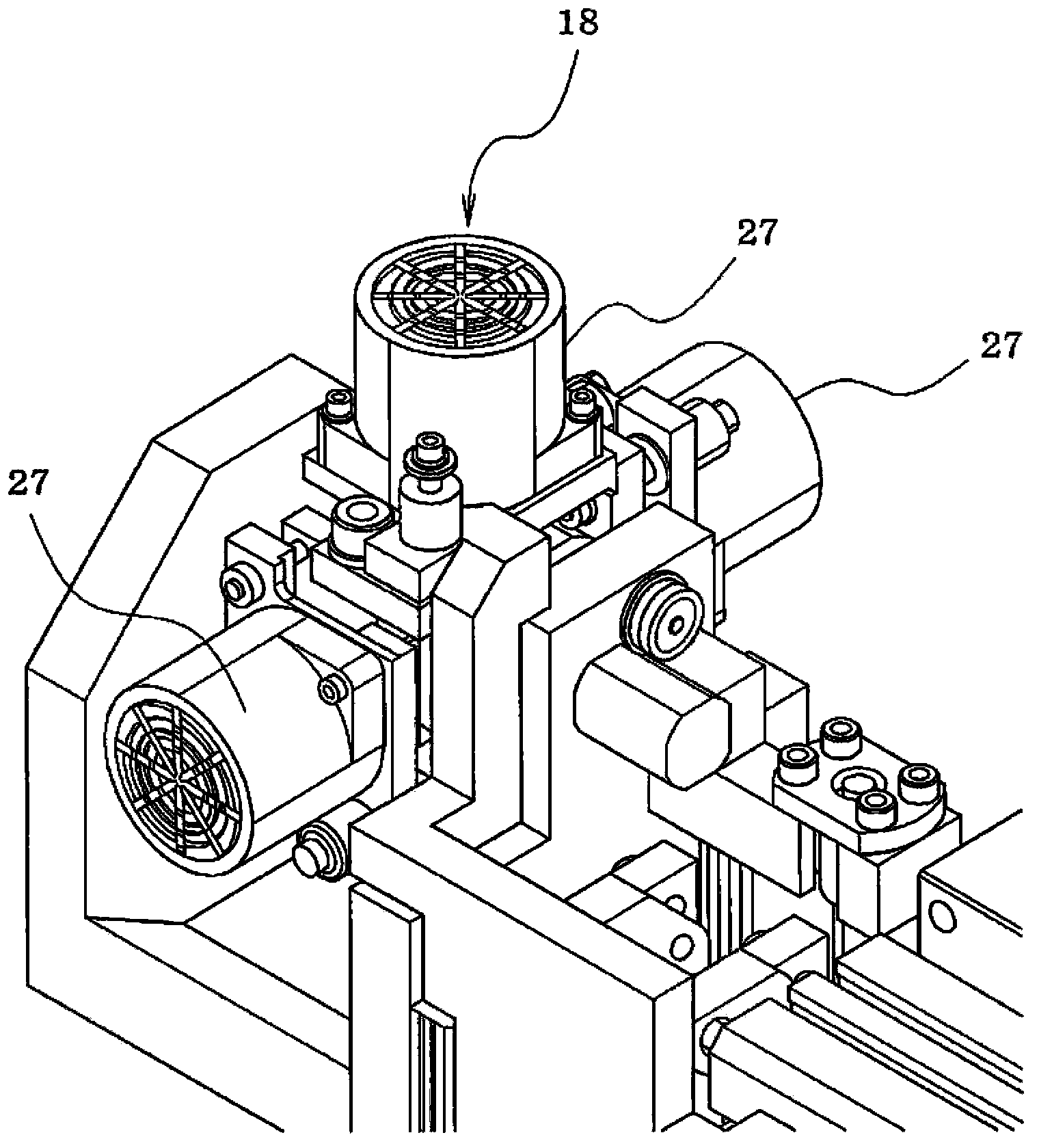

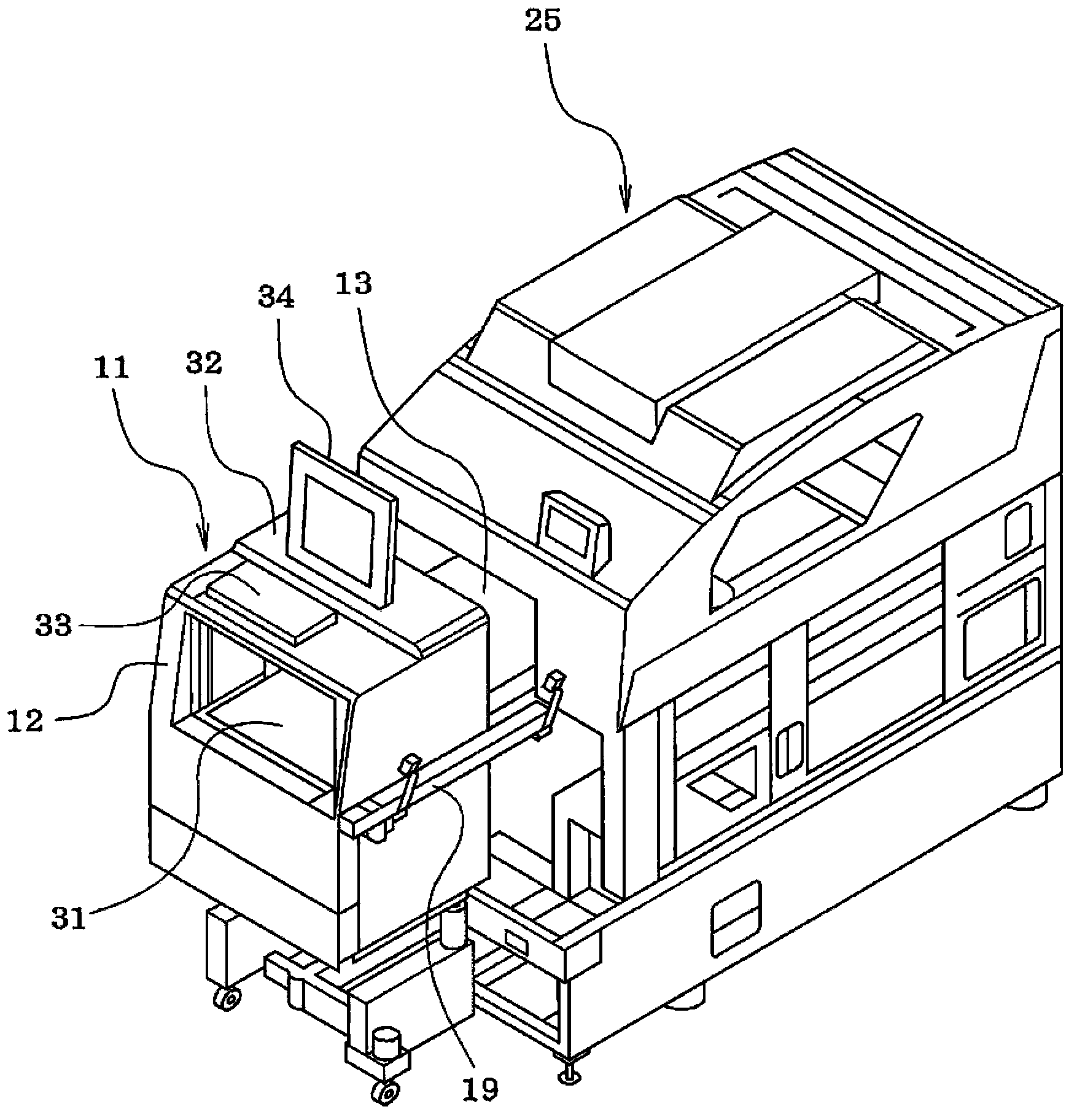

[0030] Such as figure 1 As shown, the die picking device 11 of this embodiment includes: a bin holding part 12 (pan tower), a tray pull-out platform 13, a tray pull-out mechanism 14, an auxiliary manipulator 15, a shuttle mechanism 16, a turning unit 17, and a jacking unit 18 (see figure 2 ), NG conveyor 19, nozzle changer 20, etc. Such as image 3 As shown, this die pickup device 11 is installed in a state where the tray pullout table 13 is inserted into the feeder installation slot of the component mounter 25 .

[0031] Wafer trays on which dies 21 (wafer parts) are placed can be mixed and loaded in multiple stages in a magazine (not shown) that is vertically movable in the magazine holding unit 12 of the die picker 11 22 and a tray tray (not shown) on which tray parts (electronic parts) are placed. Such as Figure 4 and Figure 5 As shown, in the wafer tray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com