Current transformer polarity test rod

A current transformer and polarity testing technology, which is applied in the field of electric power system, can solve problems such as unreliable connection between the test rod and the two poles of the current transformer, which affects the smooth progress of the test work, and reduces the work safety factor, so as to improve work safety. coefficient, simple structure, and the effect of reducing work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

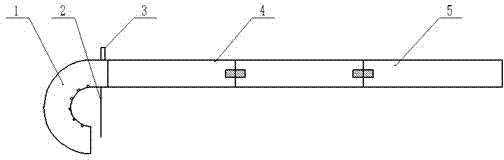

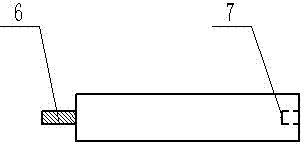

[0021] A current transformer polarity test rod, which includes a wire hook 1, an intermediate connecting insulating rod 4 and a test tail rod 5, wherein the intermediate connecting insulating rod 4 is formed by splicing two hollow insulating rods with a fixed structure . One end of the hollow insulating rod is provided with a groove 7, and the other end is provided with a metal connector 6; the fixed connection structure between two hollow insulating rods is installed on the metal connector 6 connected to the hollow insulating rod Formed in the groove 7 on the hollow insulating rod. The top end of the intermediate connecting insulating rod 4 formed by splicing hollow insulating rods is connected with the wire hook 1, and its bottom end is connected with the test tail rod 5 by a fixed structure. The connecting end of the test tail bar 5 is provided with a metal connector 6; the fixed connection structure between the test tail bar 5 and the intermediate connecting insulating ro...

Embodiment 2

[0024] A current transformer polarity test rod, which includes a wire hook 1, an intermediate connecting insulating rod 4 and a test tail rod 5, wherein the intermediate connecting insulating rod 4 is formed by splicing four hollow insulating rods with a fixed structure . One end of the hollow insulating rod is provided with a groove 7, and the other end is provided with a metal connector 6; the fixed connection structure between every two hollow insulating rods is installed on the metal connector 6 on the hollow insulating rod. Formed in the groove 7 on the hollow insulating rod. The top end of the intermediate connecting insulating rod 4 formed by splicing hollow insulating rods is connected with the wire hook 1, and its bottom end is connected with the test tail rod 5 by a fixed structure. The connecting end of the test tail bar 5 is provided with a metal connector 6; the fixed connection structure between the test tail bar 5 and the intermediate connecting insulating rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com