Arrangement method of WAT (wafer acceptance test) head

A layout method and technology of test heads, which are applied in the direction of measuring devices, measuring electrical variables, instruments, etc., to achieve the effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

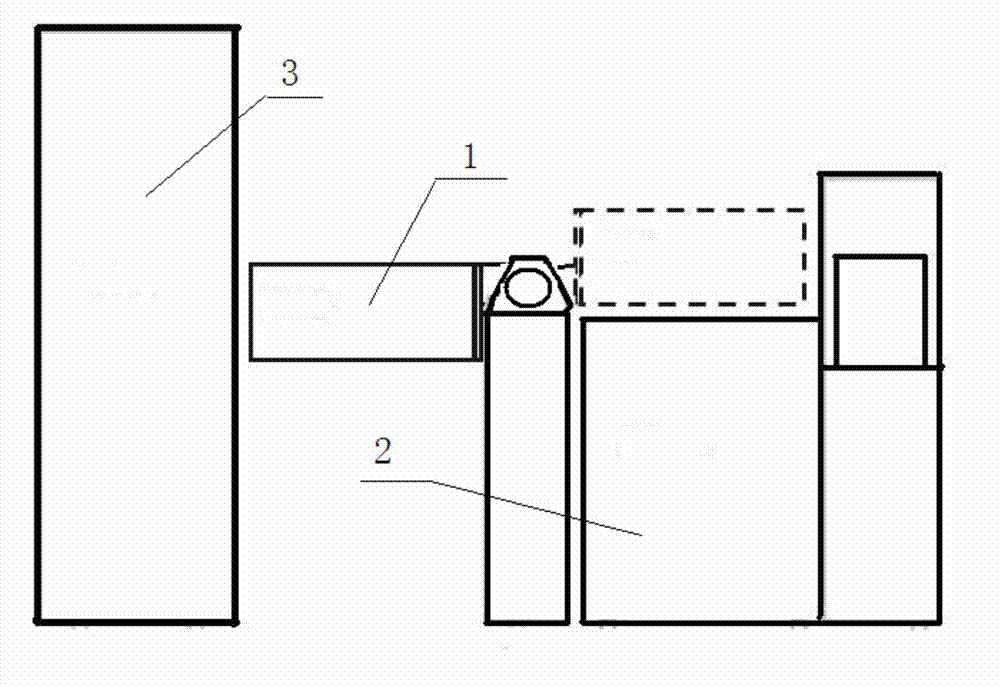

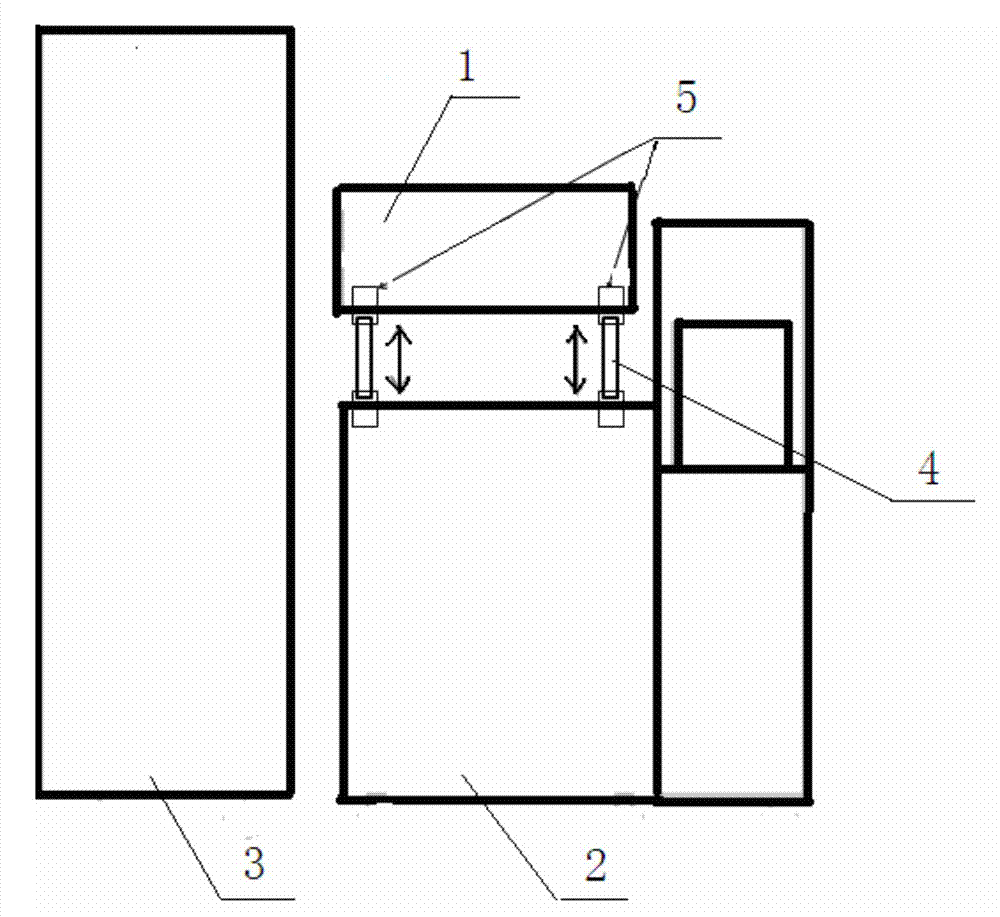

[0013] Such as Figure 1 to Figure 5 Shown, a kind of arrangement method of WAT test head, wherein, comprise: hydraulic drive device 5, described hydraulic drive device 5 comprises four hydraulically driven elevating rods 4, fixes described four on the upper surface of probe machine table 2 Hydraulically driven lifting rods 4, the four hydraulically driven lifting rods 4 are respectively fixedly connected to the four corners of the bottom surface of the test head 1; a control device (not marked in the drawings) is also provided, and the control device It is electrically connected with the hydraulic drive device 5 .

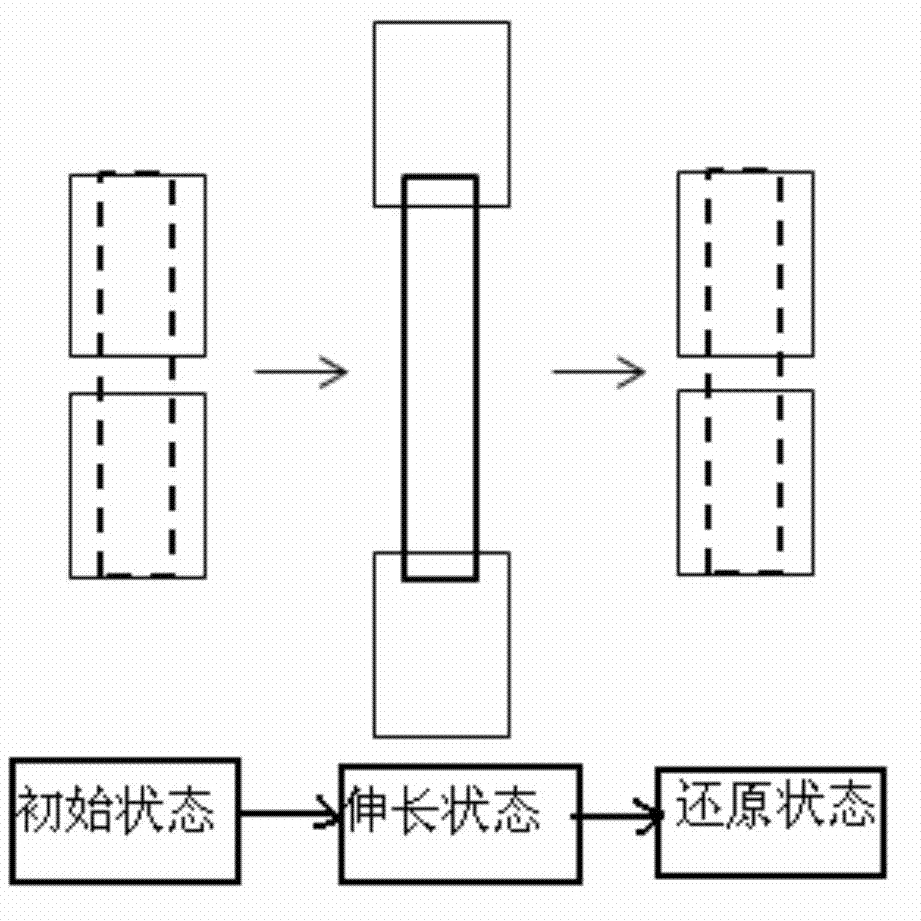

[0014] The WAT machine includes a test machine 3 and a Prober probe machine 2. Add four hydraulic transmission devices 5 to the probe machine 2 (Prober machine) and connect it to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com