Wafer?immersion?device

A wafer and wafer technology, which is applied in the field of wet wafer processing in the semiconductor industry, can solve the problems of the uniformity of soaking time and waiting time of a single wafer, and achieve the advantages of speeding up processing efficiency and uniformity, reducing process processing time and facilitating maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

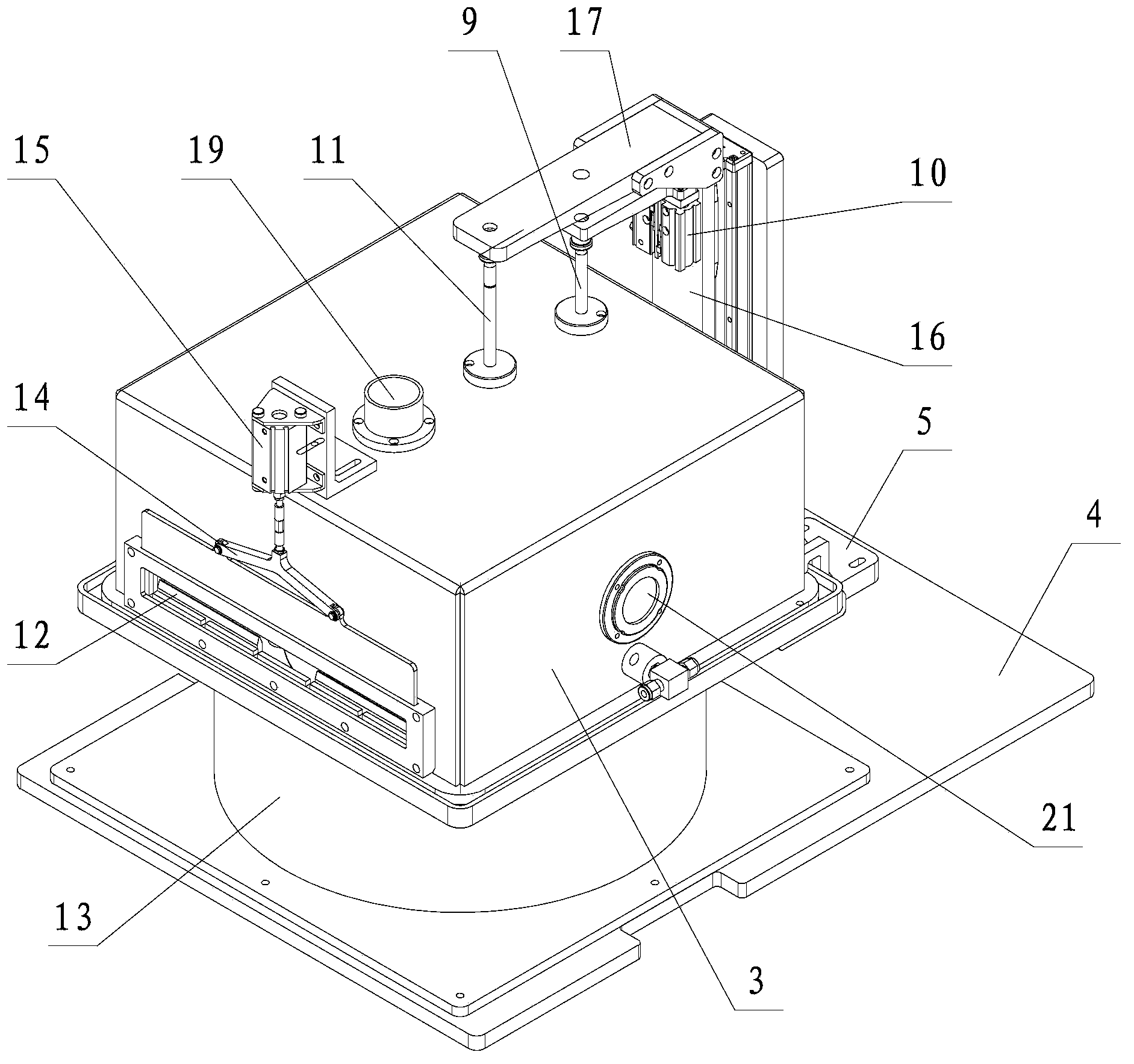

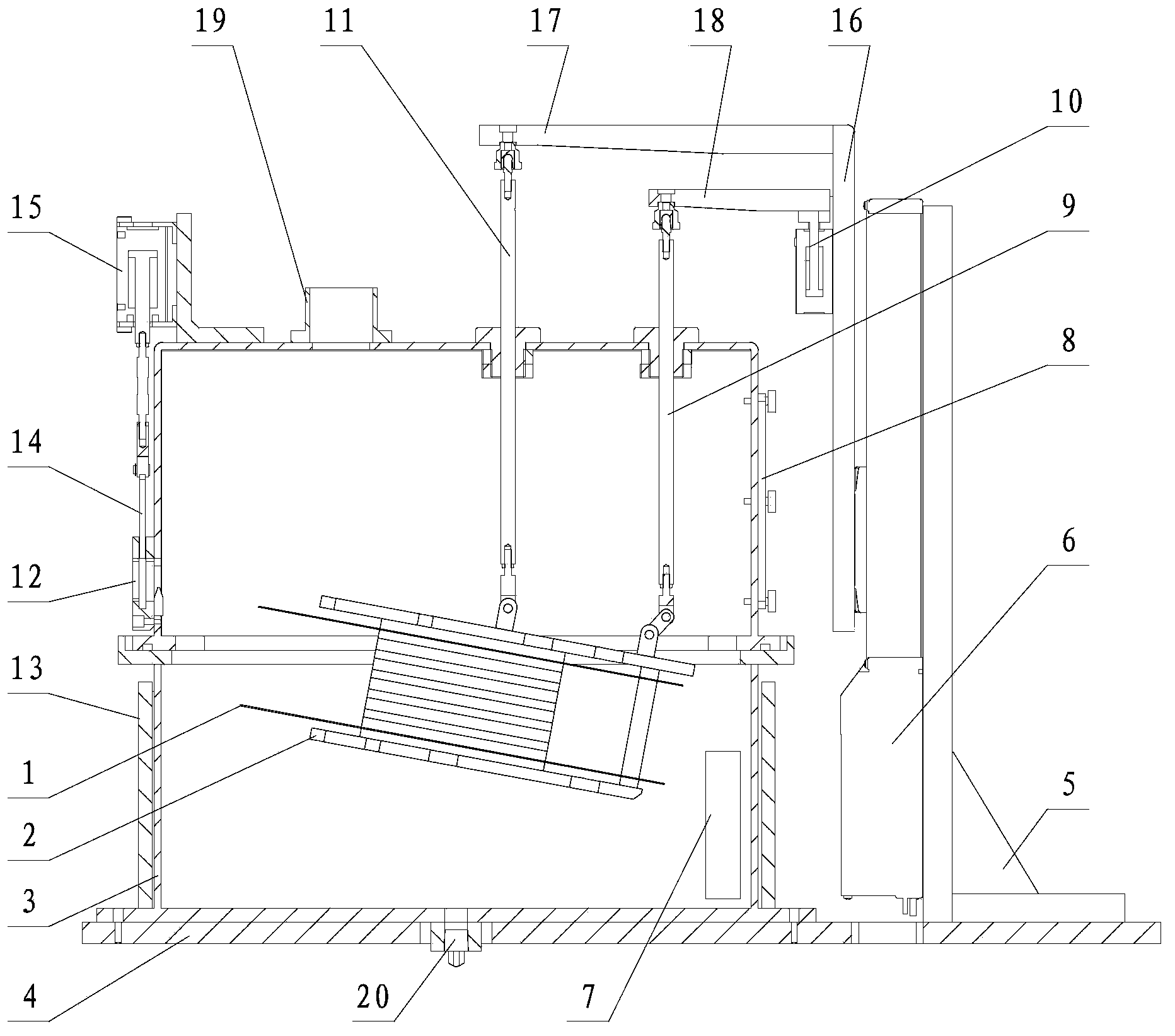

[0020] Such as figure 1 , figure 2 As shown, the present invention includes a film box 2, a liquid storage tank 3, a base plate 4, a support 5, an electric actuator 6, an ultrasonic generator 7, an inclined connecting rod 9, an inclined cylinder 10, a lifting connecting rod 11, a film transfer window 12, The heating plate 13, the baffle plate 14 and the lifting cylinder 15, wherein the liquid storage tank 3 is fixed on the bottom plate 4, is a closed cavity, the upper part of the liquid storage tank 3 is a cuboid or a cube, and the lower part is a drum shape; the electric actuator 6 passes through The bracket 5 is fixed on the bottom plate and is located on one side of the liquid storage tank 3 . Cassette 2 is located in liquid storage tank 3, and can be loaded with a plurality of wafers 1 in the cassette 2; connected, the other end is inserted into the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com