Rotor And Brushless Motor

A technology of brushless motors and rotors, which is applied in the manufacture of motor generators, electric components, synchronous motors with stationary armatures and rotating magnets, etc., and can solve problems such as easy demagnetization of excitation magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

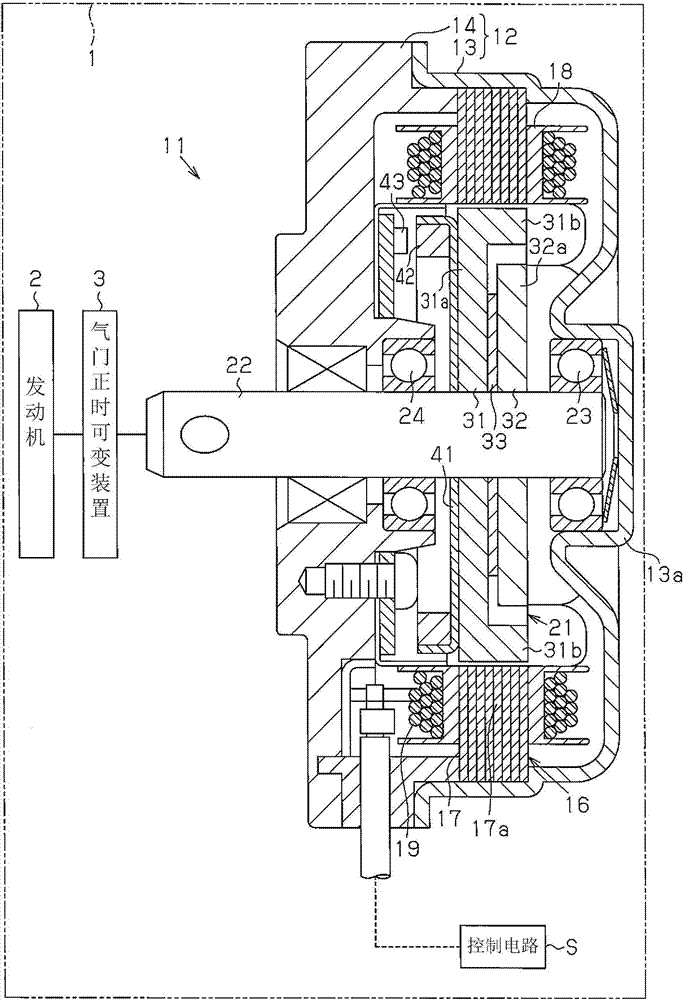

[0077] Below, according to figure 1 and figure 2 A first embodiment of the brushless motor will be described.

[0078] Such as figure 1 As shown, the brushless motor 11 of this embodiment is used in a position control device arranged in a vehicle engine compartment 1 , more specifically, in a variable valve timing device 3 connected to an engine 2 .

[0079] Such as figure 1 As shown, the motor case 12 of the brushless motor 11 has a bottomed cylindrical casing 13 and the front side of the cylindrical casing 13 ( figure 1 The front end plate 14 with the opening closed in the center and left side).

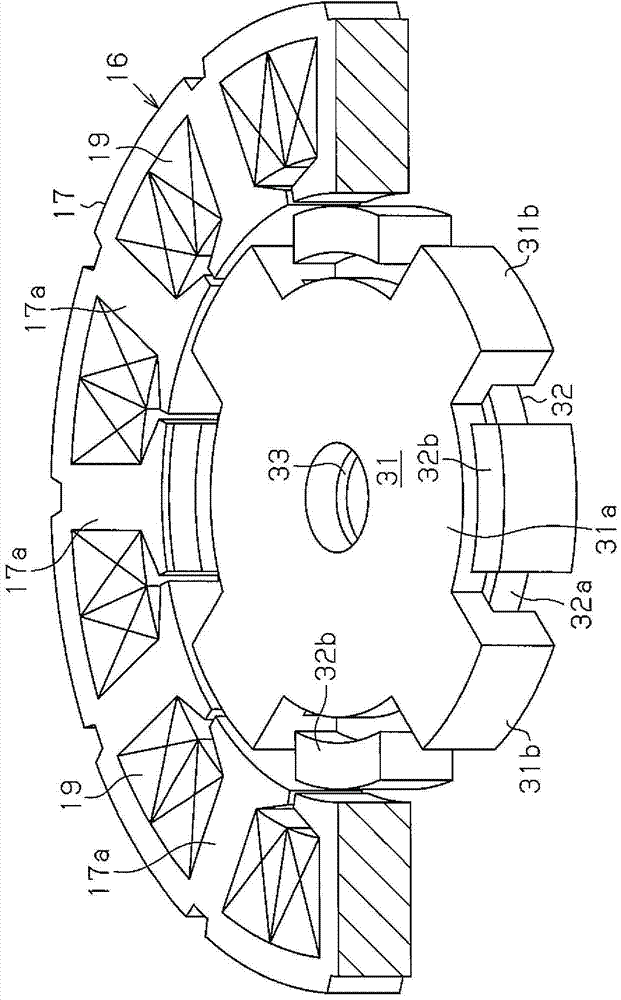

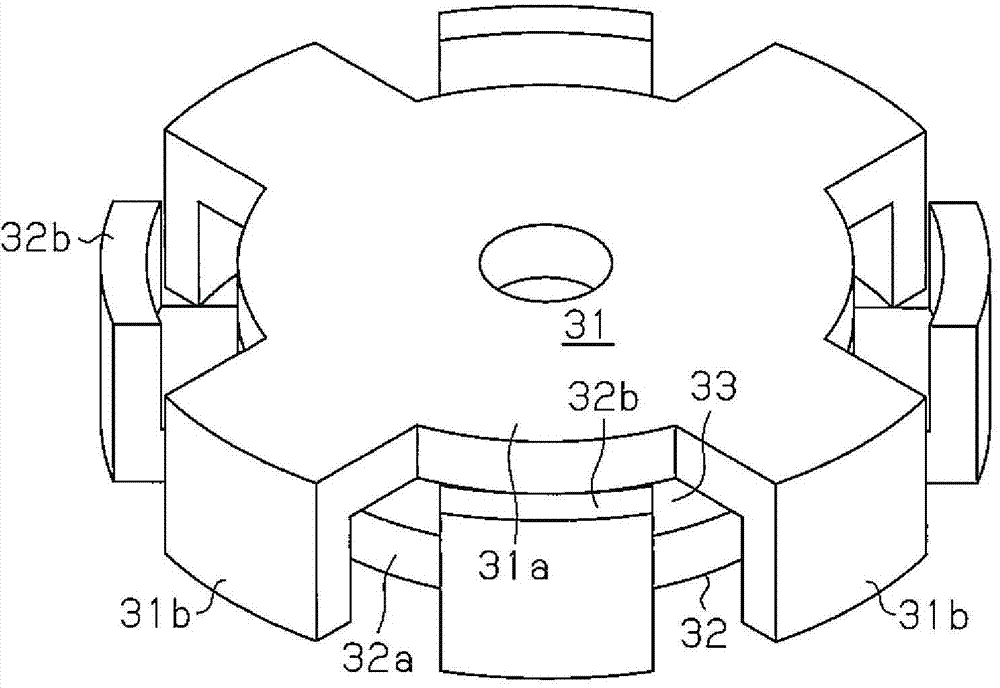

[0080] Such as figure 1 As shown, a stator 16 is fixed to the inner peripheral surface of the cylindrical housing 13 . The stator 16 includes: an armature core 17 having a plurality of (twelve in this embodiment) teeth 17a extending radially inward as concentrated winding teeth; and a winding 19 wound around the armature core 17 via an insulator 18 On the tooth 17a. The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com