Preparation method of high temperature resistance radiation orientation or multi-pole orientation neodymium iron boron annular magnet

A radiation orientation, NdFeB technology, used in the manufacture of permanent magnets, magnetic objects, inductors/transformers/magnets, etc., can solve problems such as demagnetization and parts failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In order to improve the high temperature resistance performance of the radiation-oriented or multi-pole-oriented NdFeB ring magnet, the embodiment of the present invention provides a high-temperature-resistant radiation-oriented or multi-pole-oriented NdFeB ring magnet preparation method, which specifically includes:

[0030] When preparing the high temperature resistant radiation orientation or multi-pole orientation NdFeB ring magnet of the embodiment of the present invention, the prepared radiation orientation or multi-pole orientation NdFeB ring magnet can be selected, and then the radiation orientation or multi-pole orientation The surface of the NdFeB ring magnet is coated with a coating material containing heavy rare earth elements, and the coated radiation-oriented or multi-pole-oriented NdFeB ring magnet is infiltrated with heavy rare earth elements, that is, the grain boundary Diffusion treatment.

[0031] The inventors found that by infiltrating heavy rare ea...

Embodiment 1

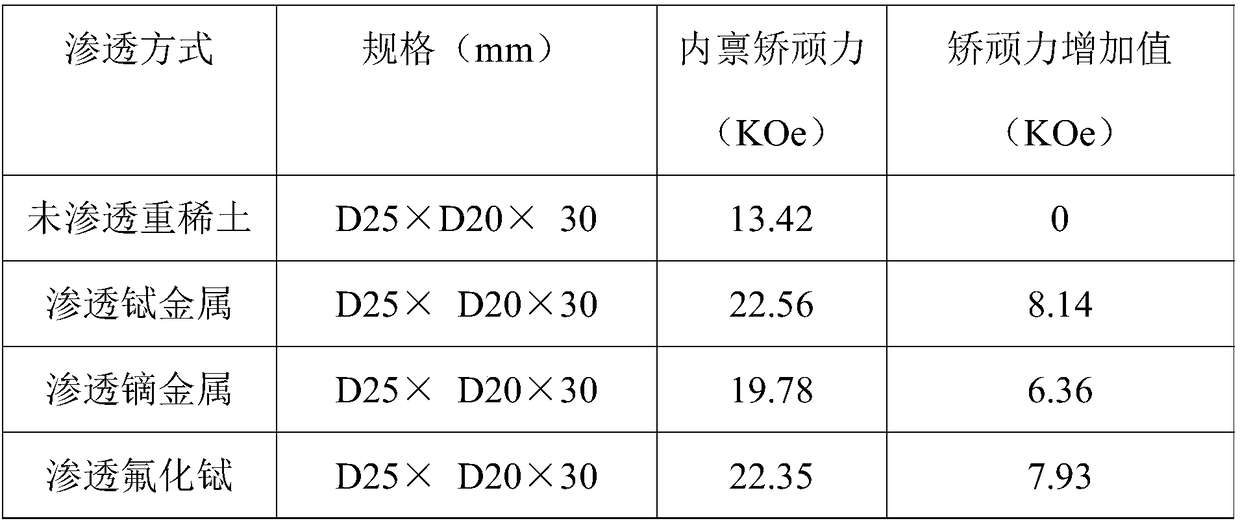

[0042] Take 9 radiation-oriented NdFeB ring magnets with the grade 38SH that have been machined and divide them into three groups of three. The first group: Vacuum sputtering on the surface of the radiation-oriented NdFeB ring magnets One layer of terbium metal coating, the coating weight is 0.5% of the ring weight, the second group: a layer of dysprosium metal coating is vacuum sputtered on the surface of the radiation-oriented NdFeB ring magnet, and the coating weight is the ring weight 0.5% of 0.3%, the third group: a layer of terbium fluoride powder coating is coated on the surface of the radiation-oriented NdFeB ring magnet, and the coating weight is 0.5% of the weight of the ring. Put three groups of coated radiation-oriented NdFeB ring magnets into a vacuum infiltration furnace for infiltration treatment of heavy rare earth elements. The infiltration temperature is 900°C and the infiltration time is 4 hours. 5 hours; the aging-treated radiation-oriented NdFeB ring magne...

Embodiment 2

[0046] Take 9 radially oriented NdFeB ring magnets of the grade 38SH that have been machined, and use the same grouping method, the same coating and the same coating method as in Example 1 to treat three groups of radially oriented NdFeB magnets. Boron ring magnet. Put three groups of coated NdFeB ring magnets into a vacuum infiltration furnace for heavy rare earth element infiltration treatment. The infiltration temperature is 600°C and the infiltration time is 20 hours, and then aging treatment is performed at a treatment temperature of 400°C and a holding time of 20 hours; The aging-treated radiation-oriented NdFeB ring magnet is subjected to gas quenching treatment, and the surface is coated with epoxy resin to obtain a high-temperature-resistant radiation-oriented NdFeB ring magnet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com