Axle and production method

一种轴件、轴管的技术,应用在轴和制造领域,能够解决尺寸稳定性和强度困难、结构复杂、成本昂贵等问题,达到高制造精度和尺寸稳定性、成本节省、质量减小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention relates to a shaft (1), especially a drive shaft, for a vehicle, especially a trailer. The invention also relates to a rocker assembly ( 6 ) for such an axle and a vehicle equipped with the axle ( 1 ). Furthermore, the invention relates to a manufacturing method.

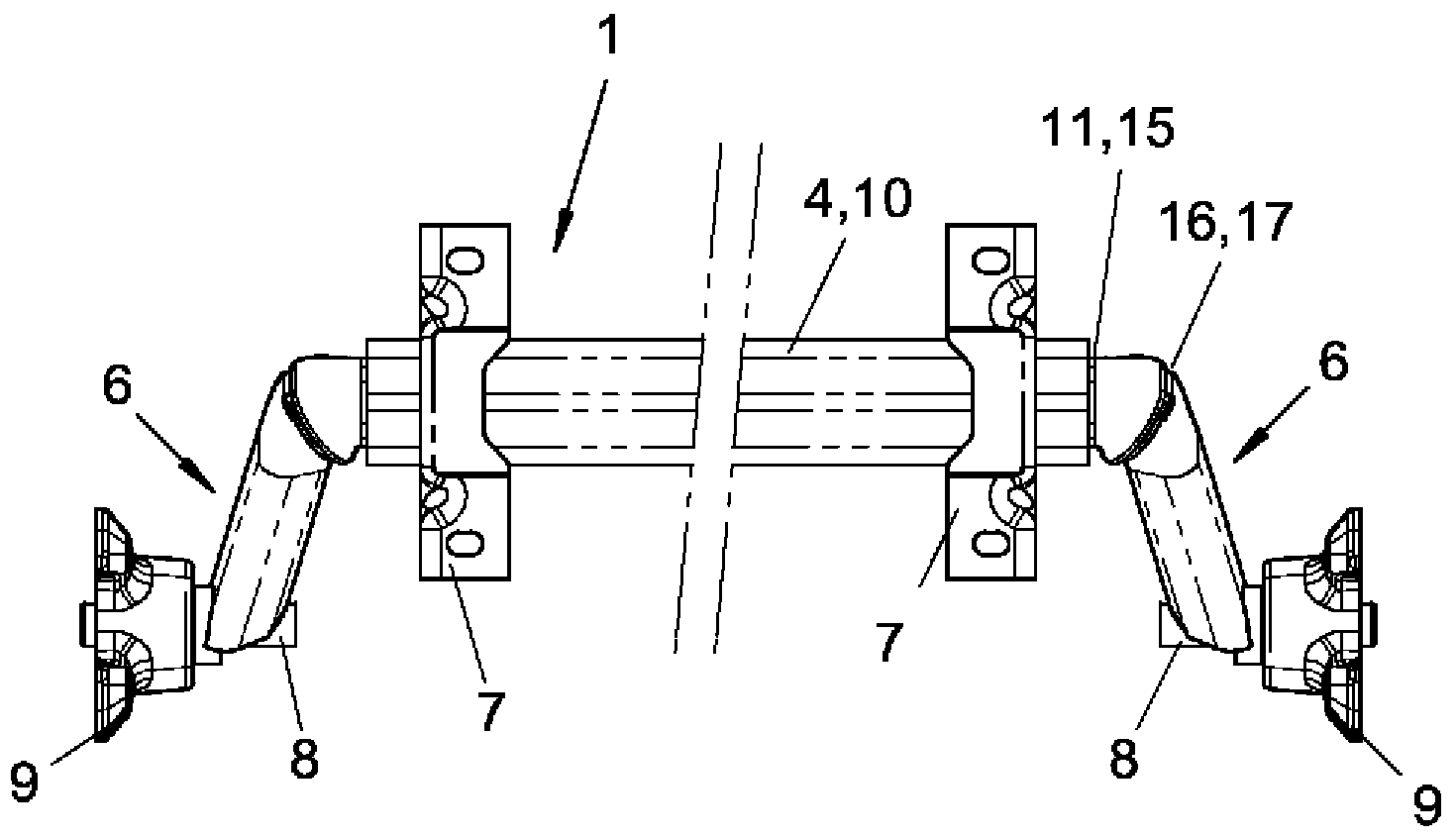

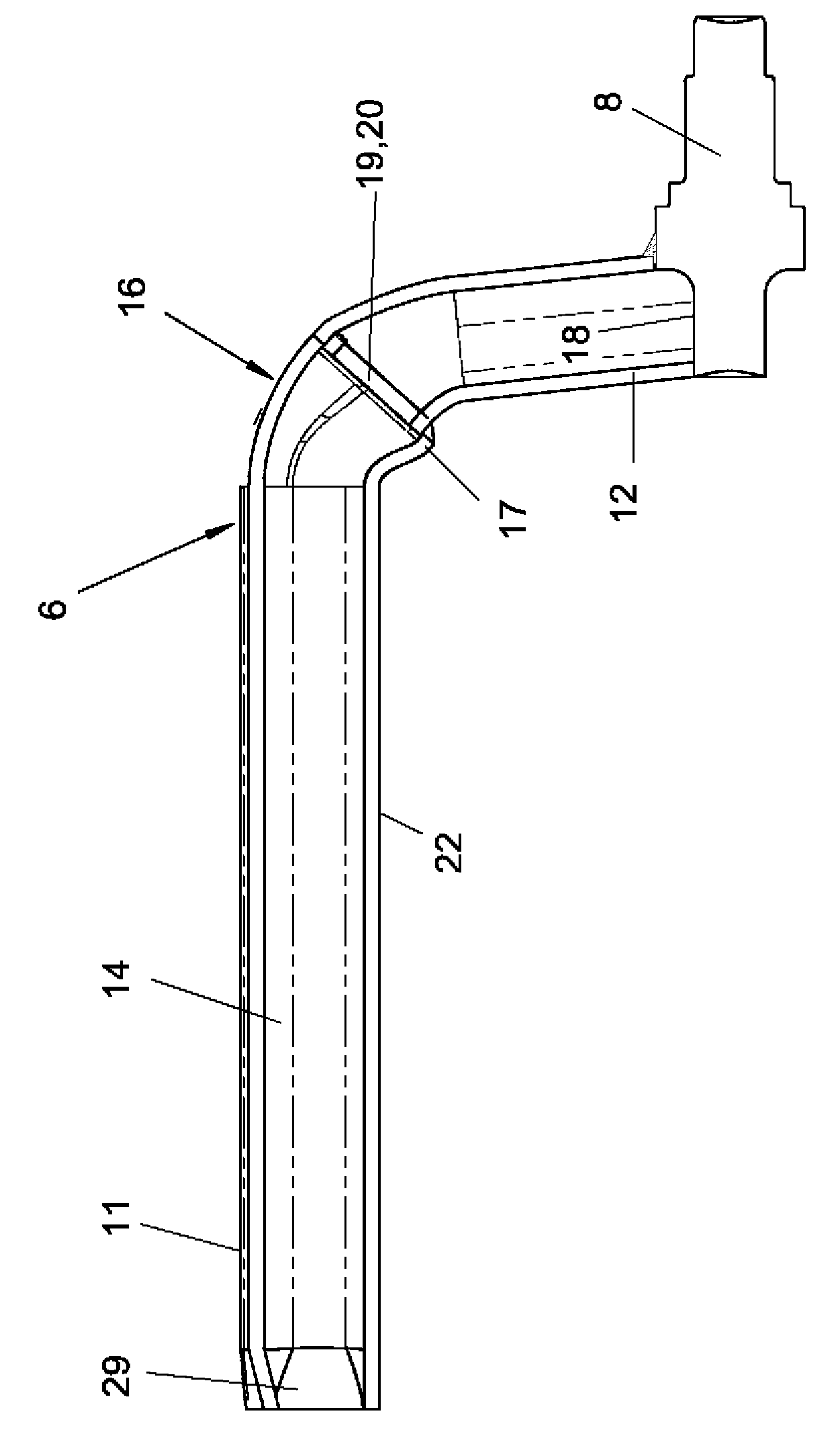

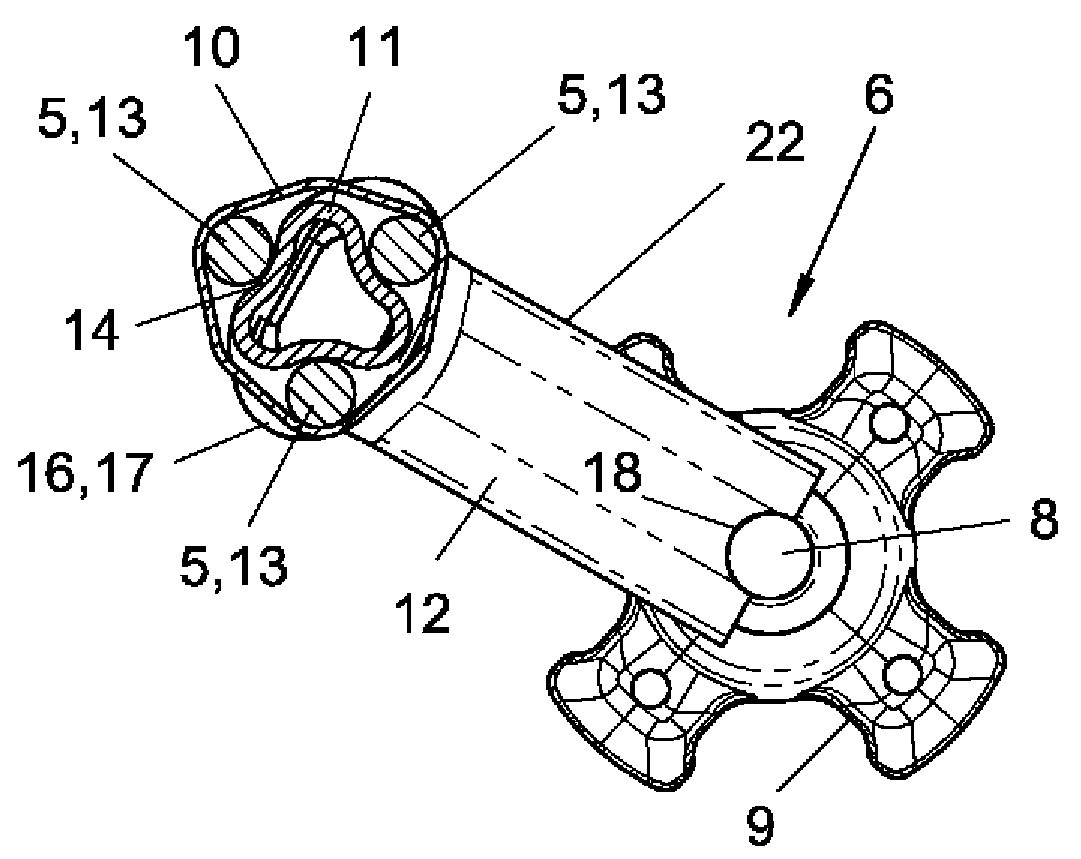

[0030] figure 1 An example of such a shaft ( 1 ) is shown, which is designed here, for example, as a non-braking transmission shaft. The shaft (1) has a shaft body (4) and a rocker assembly (6) supported thereon, which carries the hub (9) and the wheels (see Figures 15 to 18 ). Furthermore, the axle (1) has a suspension (5) for the rocker assembly (6) and is designed, for example, as a rubber spring axle.

[0031] In the embodiment shown, rocker assemblies ( 6 ) are present at both ends of the axle body ( 4 ). In a variant not shown, the shaft ( 1 ) can be designed as a separate shaft, on its two shortened shaft bodies ( 4 ), the rocker assembly ( 6 ) is supported on only one side in each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com