Flue ozone distributor, and arrangement mode and application thereof

A distributor and flue technology, applied in the field of environmental engineering, can solve problems such as harm to human health, environment, ecology and social economy, and achieve the effect of simple structure, convenient installation and guaranteed mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

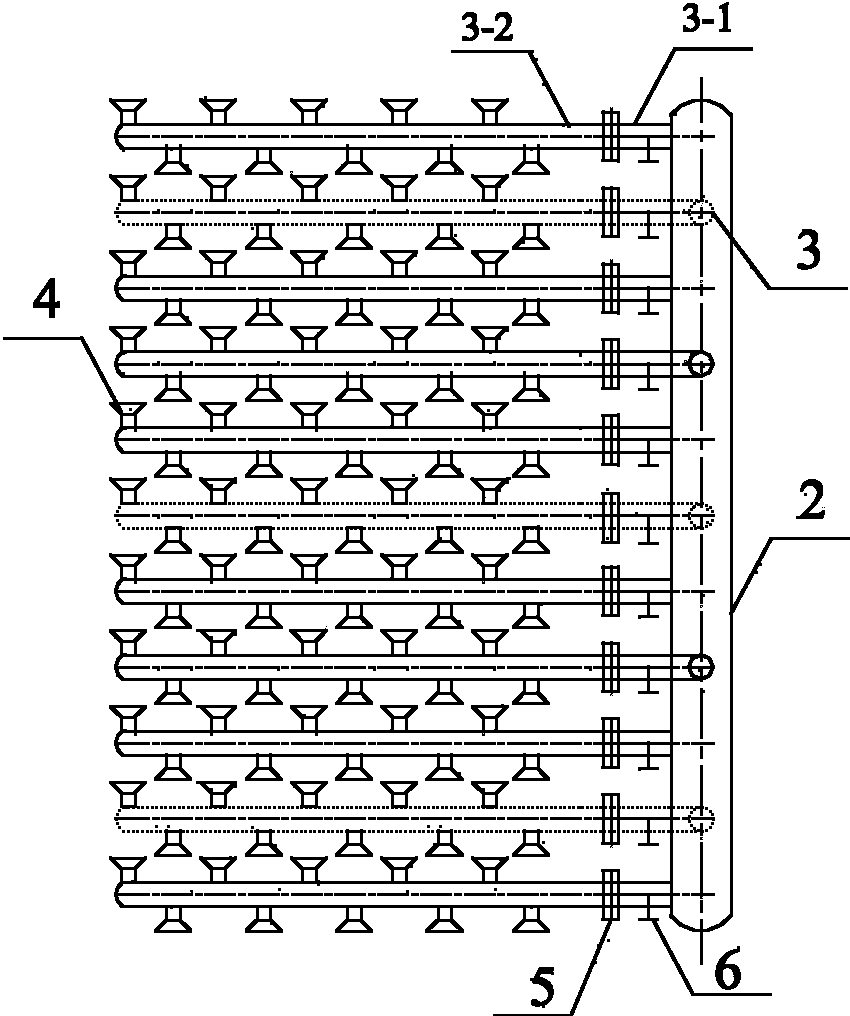

[0046] A flue ozone distributor, the flue ozone distributor includes a distribution main pipe, a plurality of distribution branch pipes and a plurality of Venturi distributors; the plurality of distribution branch pipes are drawn from different longitudinal sections of the distribution main pipe in parallel, and multiple The distribution branch pipes are arranged in a staggered manner; the multiple Venturi distributors are arranged symmetrically and staggered on both sides of the distribution branch pipes.

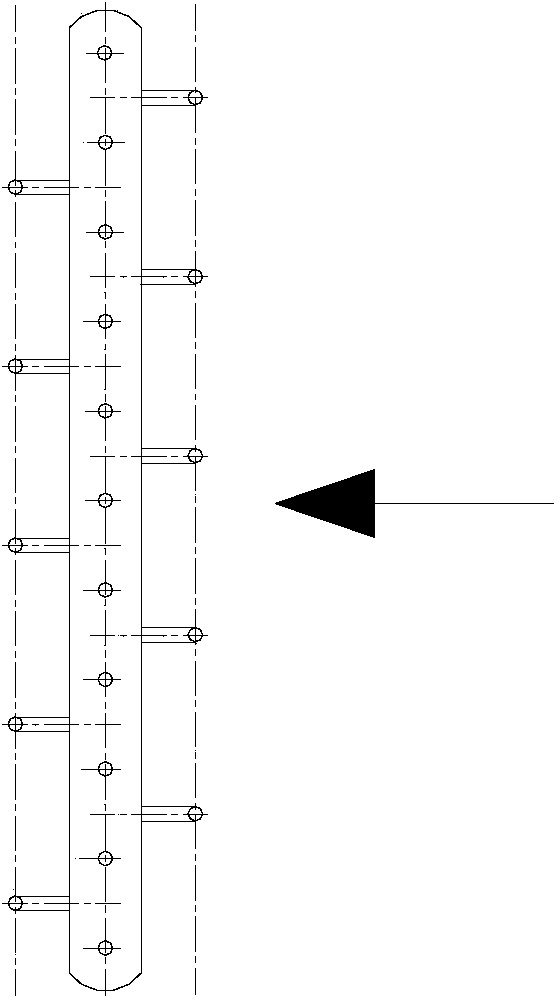

[0047] When the flue ozone distributor is arranged in the flue, the multiple Venturi distributors in the flue ozone distributor are perpendicular to the flue gas flow direction, and the horizontal distance between the ends of the multiple distribution branch pipes and the side wall of the flue is the flue 1 / 2 of the width. Even groups of flue ozone distributors are installed symmetrically and misplaced on both sides of the flue.

Embodiment 2

[0049] Such as Figure 1 to Figure 3 Shown, a kind of flue ozone distributor, described flue ozone distributor comprises distribution main pipe 2, a plurality of distribution branch pipes 3 and a plurality of Venturi distributors 4; The vertical section is branched out in parallel, and a plurality of distribution branch pipes 3 are arranged in a staggered manner;

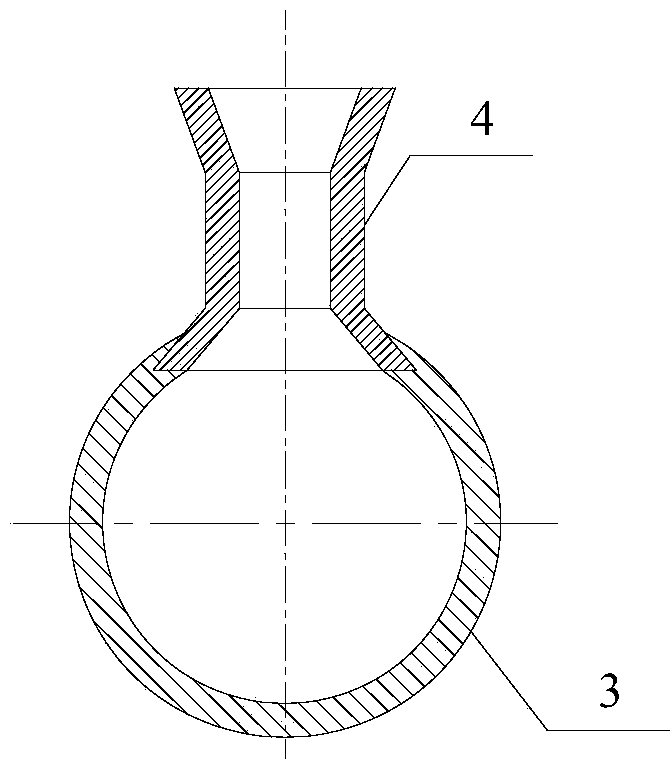

[0050] The distribution branch pipe 3 is divided into two sections, the front distribution branch pipe 3-1 section is drawn out from the distribution main pipe 2, and the rear distribution branch pipe section 3-2 is connected by a connecting flange 6. The front distribution branch pipe 3-1 is provided with a regulating valve 6, which can regulate the amount of ozone passing through according to the NO concentration in the flue gas. The distance between the different longitudinal sections is 200mm. The spacing between the centerlines of adjacent distribution branch pipes 3 of different longitudinal sections is equa...

Embodiment 3

[0057] The difference between this embodiment and embodiment 2 is:

[0058] The distance between the different longitudinal sections is 100mm. The distance between the centerlines of adjacent distribution branch pipes 3 of different longitudinal sections is 300mm.

[0059] The air velocity in the distribution main pipe 2 is 25m / s; the air velocity in the distribution branch pipe 3 is controlled at 20m / s.

[0060] The distance between two adjacent Venturi distributors 4 on the same distribution branch pipe 3 on the same side is 50mm.

[0061] The constriction angle of the Venturi distributor 4 is 70°, and the divergence angle is 25°.

[0062] The throat height-diameter ratio of the Venturi distributor 4 is 1.0, and the gas velocity at the throat is 8m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com