Production system for anti-pollution chemical coating on surface of metal in water

A chemical coating and production system technology, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc., can solve problems such as inactivation of liquid coatings, reduced stirring effect, and overcooling. To achieve the effect of low manufacturing cost, maintain the best properties, and avoid partial overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

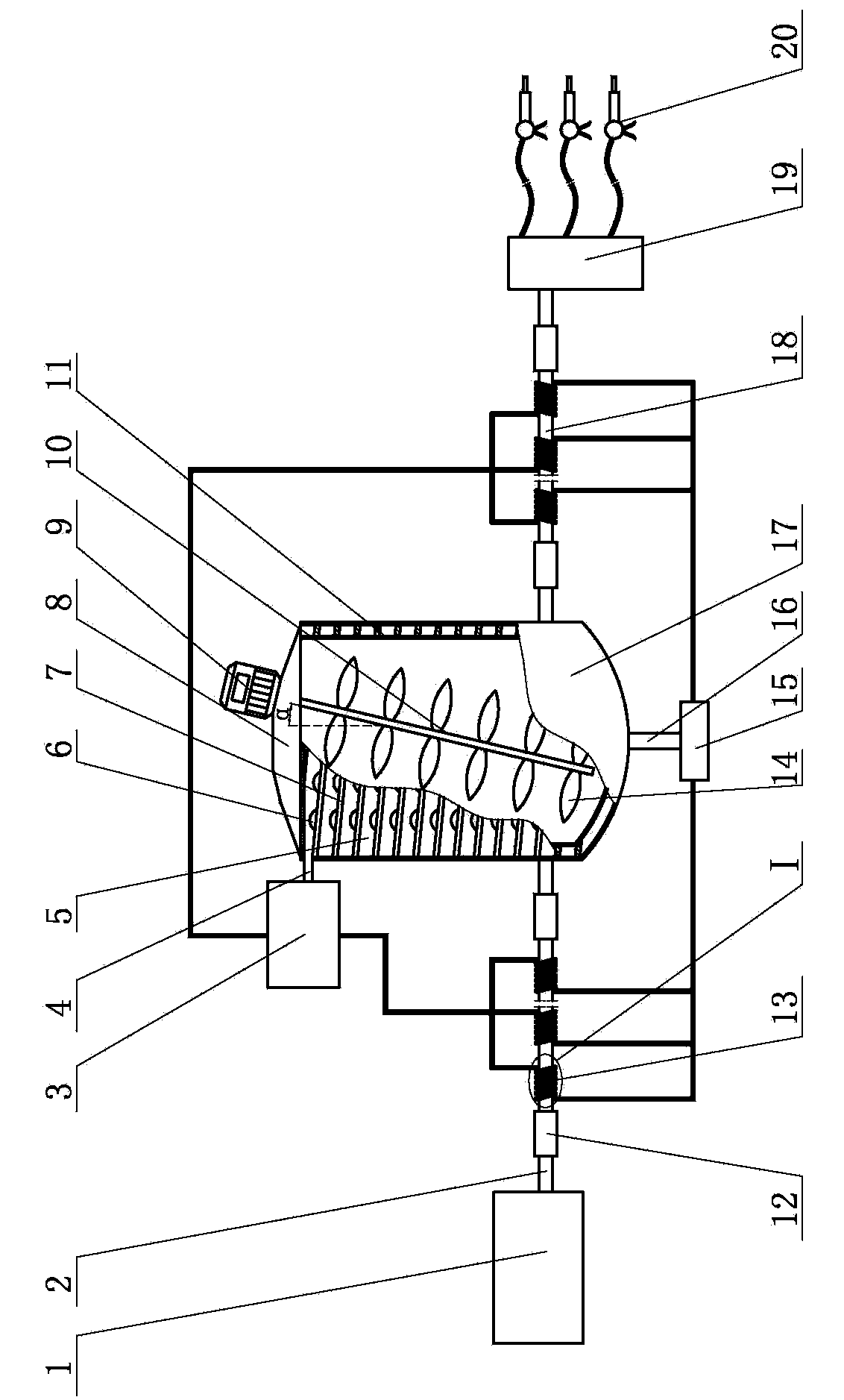

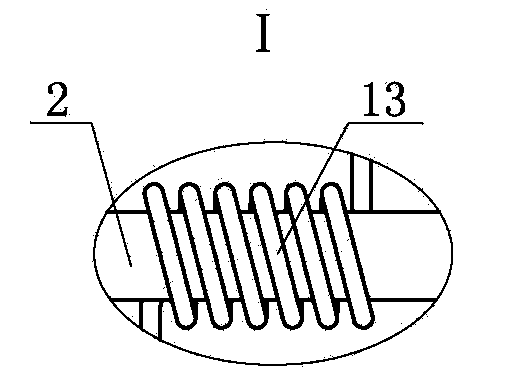

[0009] Production systems for metal anti-pollution chemical coatings in water, such as figure 1 Shown, comprise solid melting furnace 1, agitator and liquid storage tank 19, feed pipe 2 is set between solid melting furnace 1 and agitator, discharge pipe 18 is set between agitator and liquid storage tank 19, agitator includes The outer shell 17, the inner shell 11 and the top cover 8, the inner shell 11 is provided with the stirring shaft 10, the stirring blade 14 is arranged on the stirring shaft 10, the stirring motor 9 is installed on the top cover 8, the output shaft of the stirring motor 9 is connected to the stirring shaft 10, and the outer shell 17 and the inner shell 11 are provided with a spiral partition 7, the upper part of the outer shell 17 and the inner shell 11 is provided with a liquid inlet pipe 4, and the lower part of the outer shell 17 is provided with a liquid outlet pipe 16, and the liquid inlet pipe 4 and the liquid outlet pipe 16 are connected. heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com