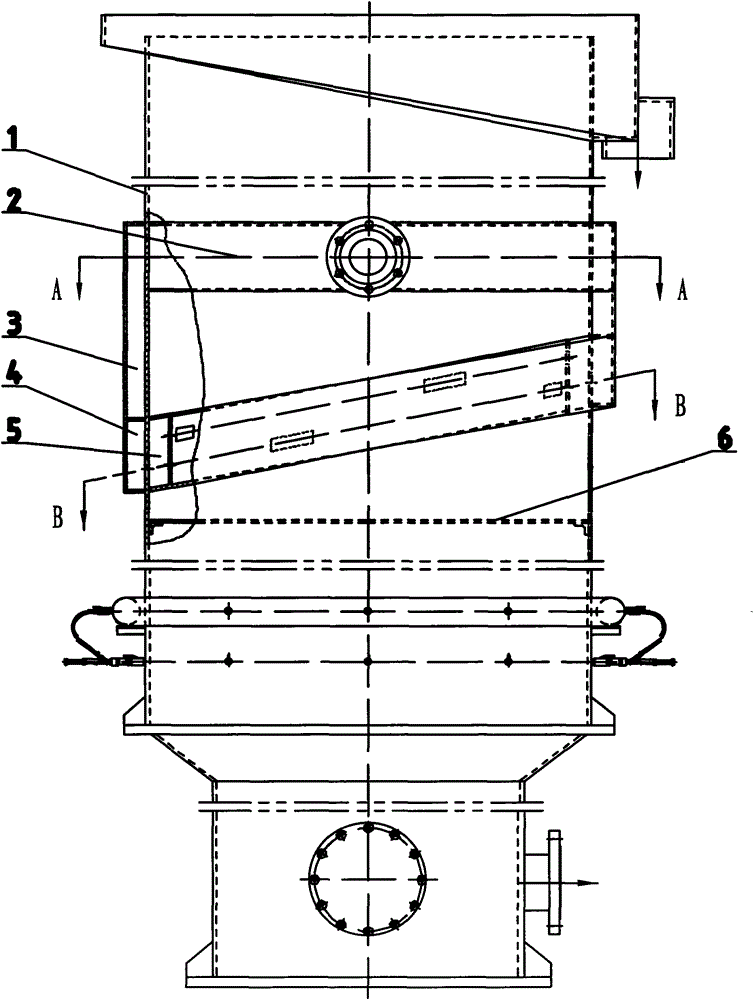

Feeding device of inflatable flotation column

A flotation column, inflatable technology, used in flotation, solid separation and other directions, can solve the problems of uneven distribution of feed, unstable feed, easy bubble breakage, etc., to achieve good mineralization effect of raw ore, feed distribution Uniform, good flotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

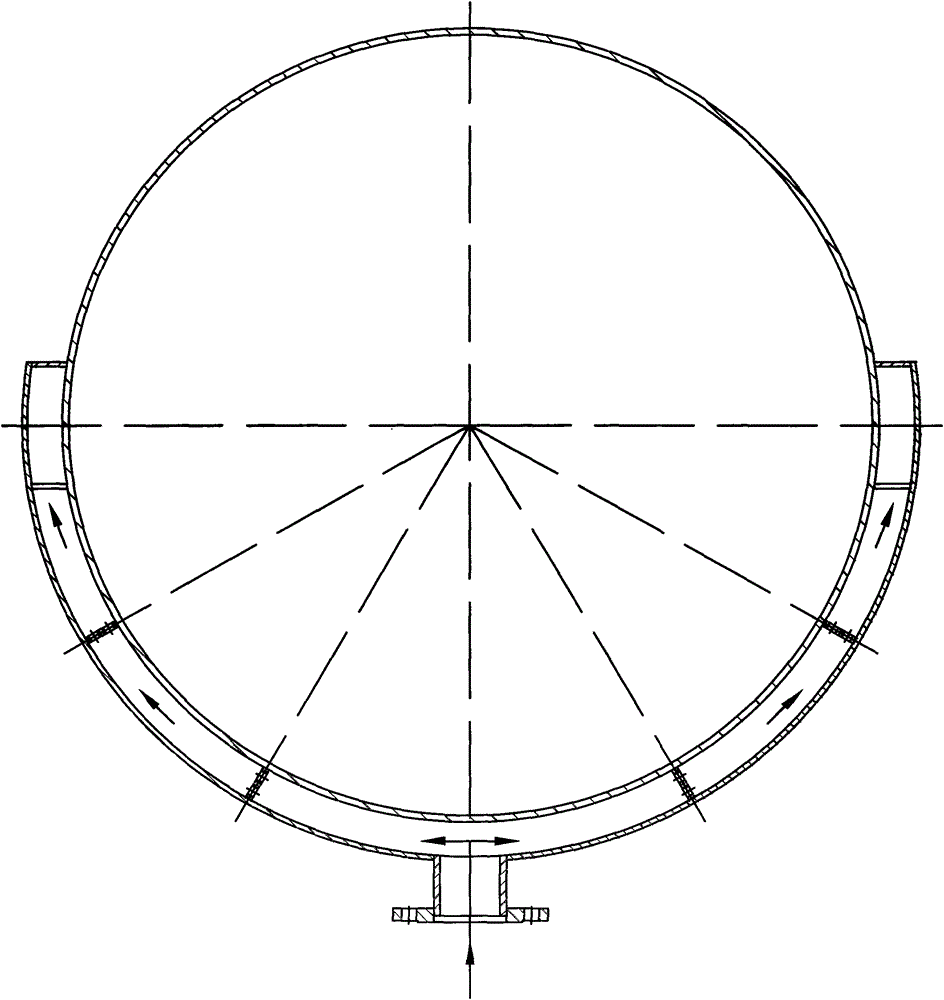

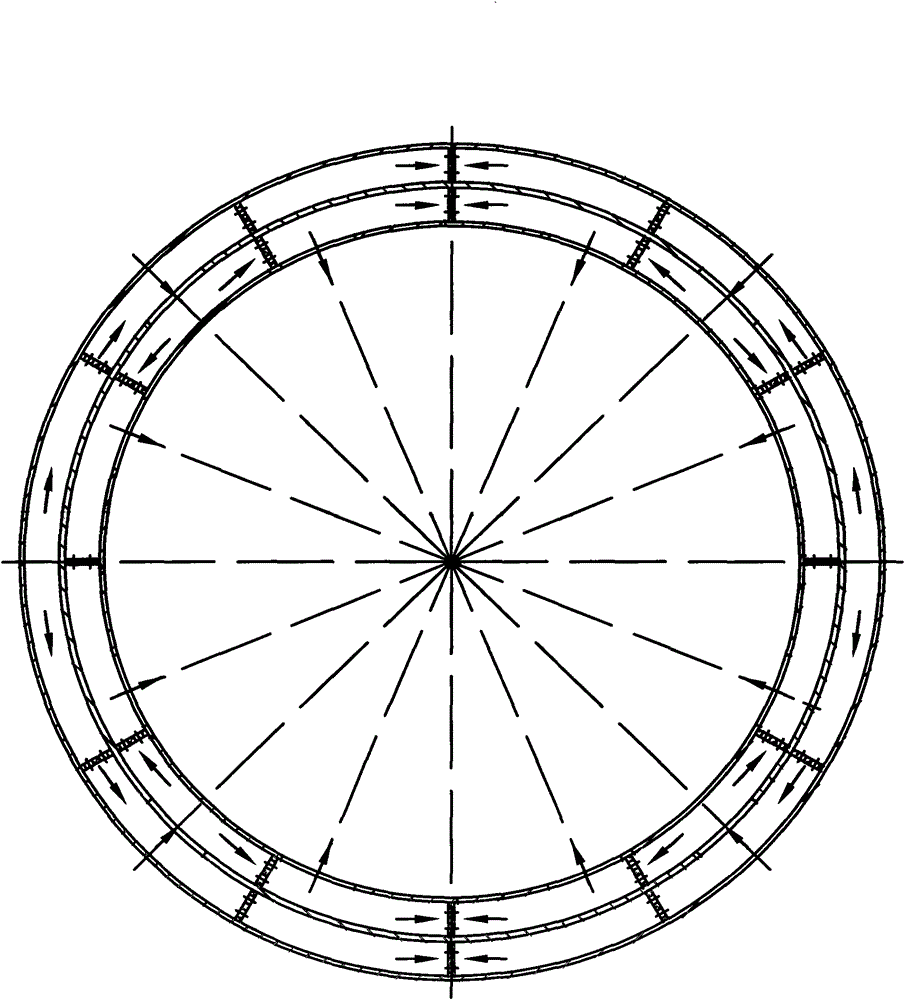

[0020] As shown in the figure: the selected ore pulp transported into the feeding tank 2 is transported to the outer tank 4 through the splitter tank 3, and then flows to the inner tank 5 through four holes on the side wall of the upper column 1 connected to the outer tank Then, through the eight rectangular outlets inside the inner tank 5, the flow is diverted to the cross section of the upper column 1, and the pulp that cannot be floated drops to the sieve plate 6 and collides with the rising air bubbles countercurrently, further improving the recovery rate of the flotation concentrate .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com