Roller used for separating sand and stone

A sand and gravel separation and roller technology, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of waste of tap water and concrete materials, incomplete separation, and unfavorable environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

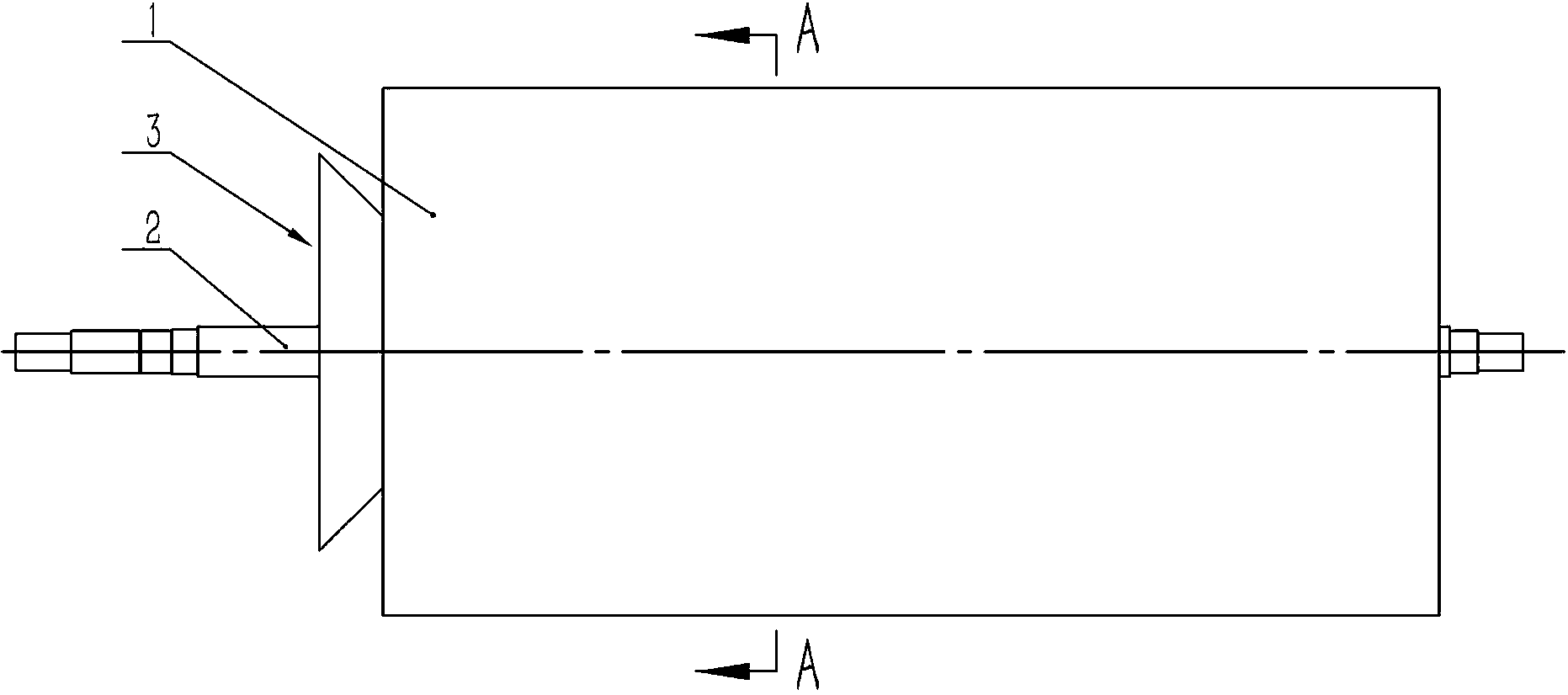

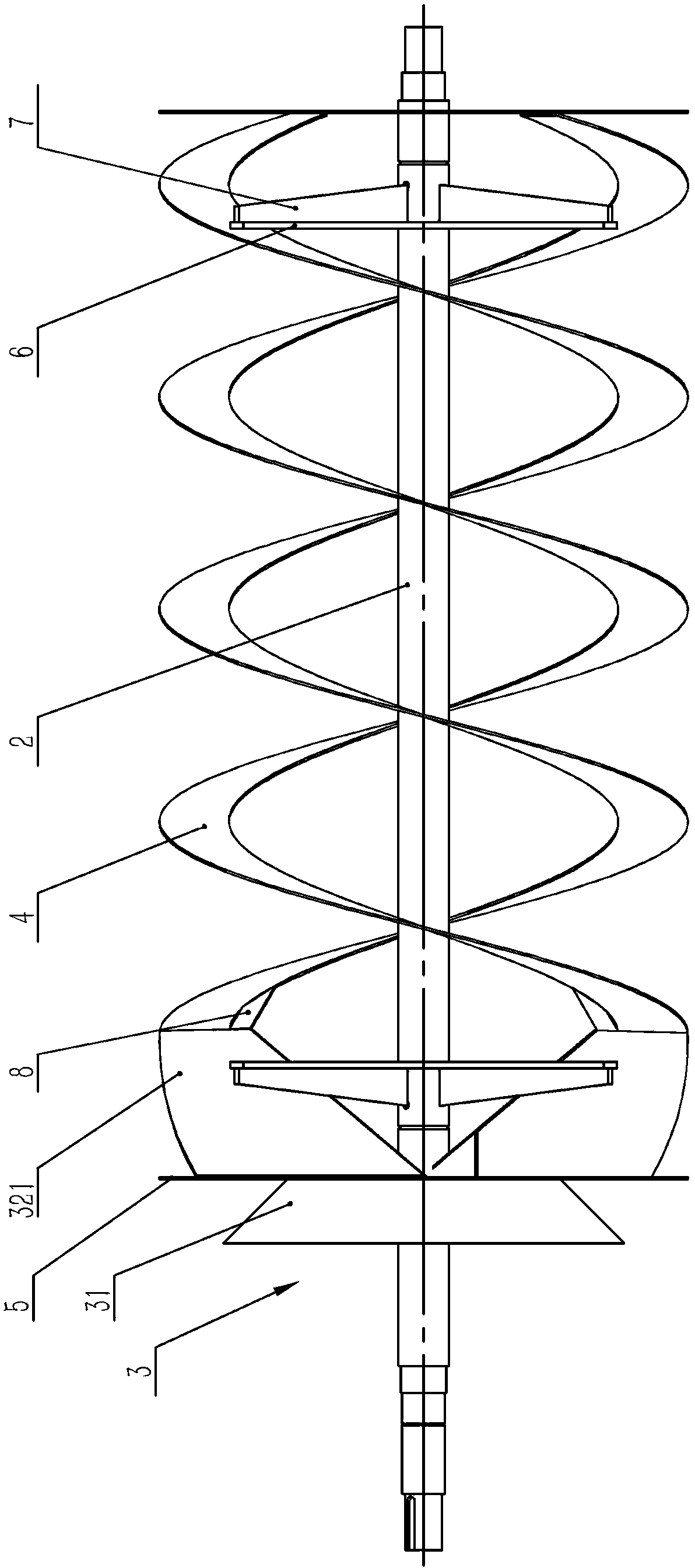

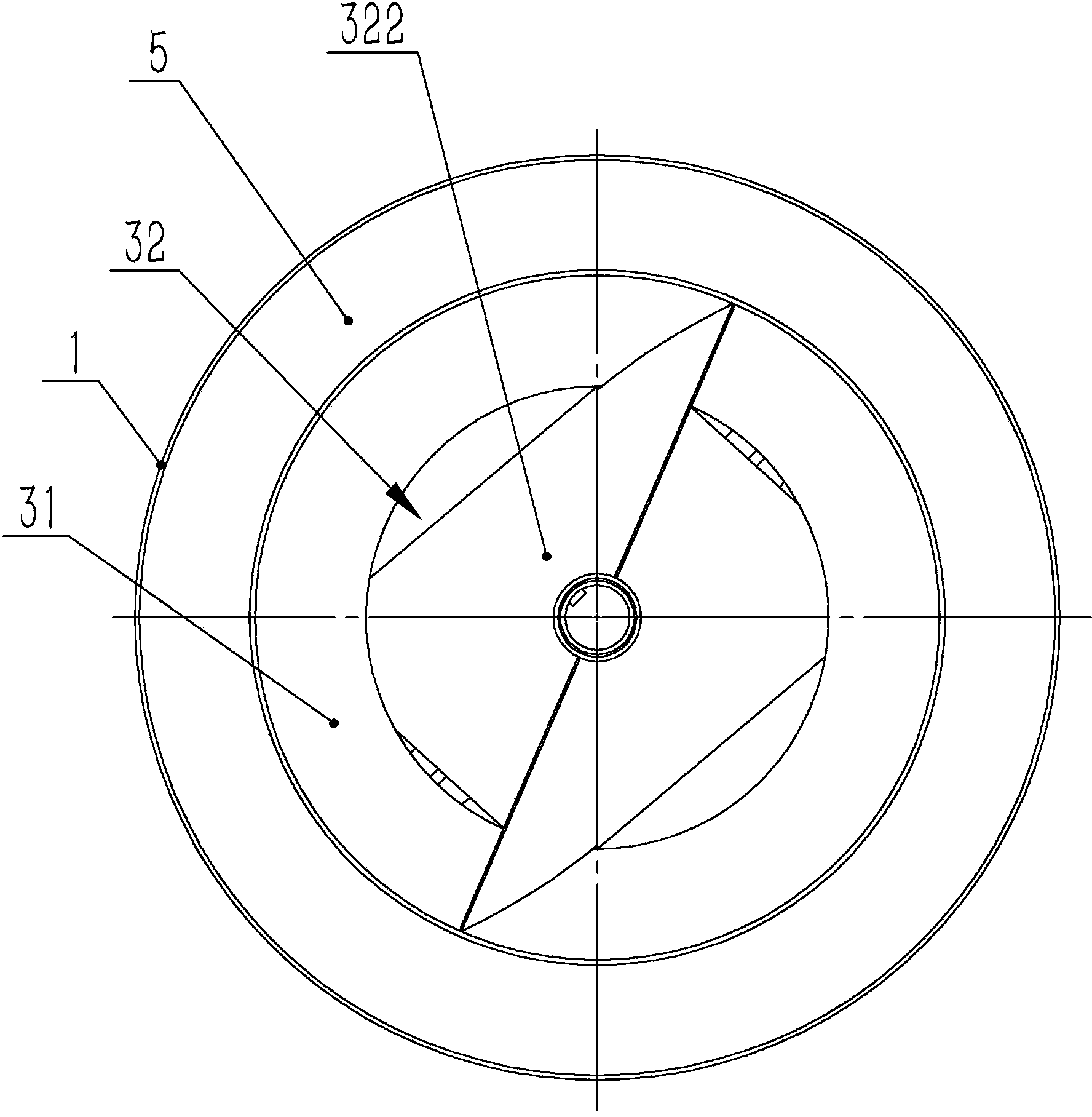

[0015] like Figure 1 to Figure 5 As shown, the drum used for sand and gravel separation disclosed in the present invention includes a screen-type cylinder 1 , a rotating shaft 2 and a discharge device 3 . The inner wall of the cylinder 1 has double-headed helical blades 4 arranged symmetrically about its axial centerline. There are annular sealing plates 5 at both ends of the cylinder 1, wherein the width of the annular sealing plate 5 near the end of the discharge device 3 is consistent with the width of the helical blade 4, and the width of the annular sealing plate 5 at the other end is greater than the width of the helical blade 4. Both ends of the rotating shaft 2 protrude from the cylindrical body 1 . A support plate 6 in the shape of a cross is welded to the inner wall of the cylinder body 1 on the rotating shaft 2 , and reinforcing ribs 7 are provided on the support plate 6 .

[0016] The discharge device 3 is located at the end of the cylinder body corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com