Unilateral broaching involute internal spline deburring broach

An internal spline and involute technology, which is used in the field of unilateral broaching of involute internal spline deburring broaches, can solve the problems of workpiece deflection, deviated tooth flanks, and burrs, so as to reduce the scrap rate of parts and ensure Dimensional accuracy, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

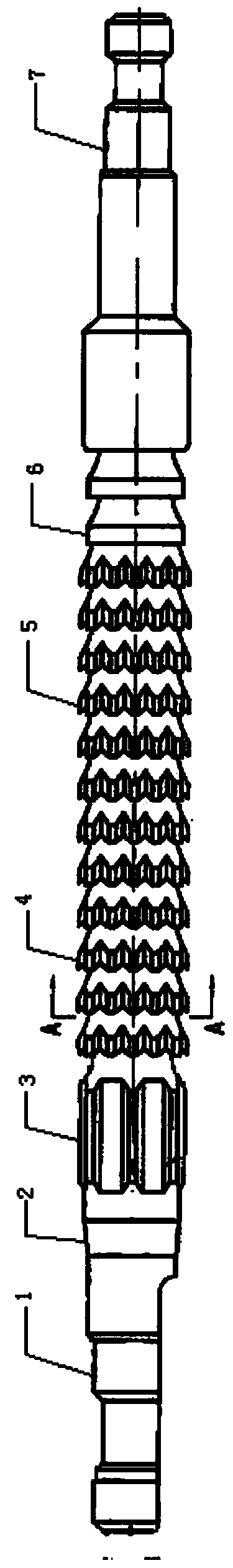

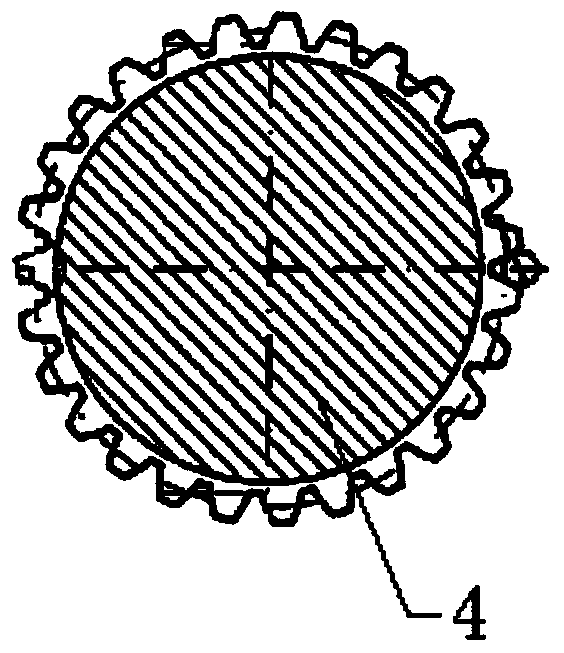

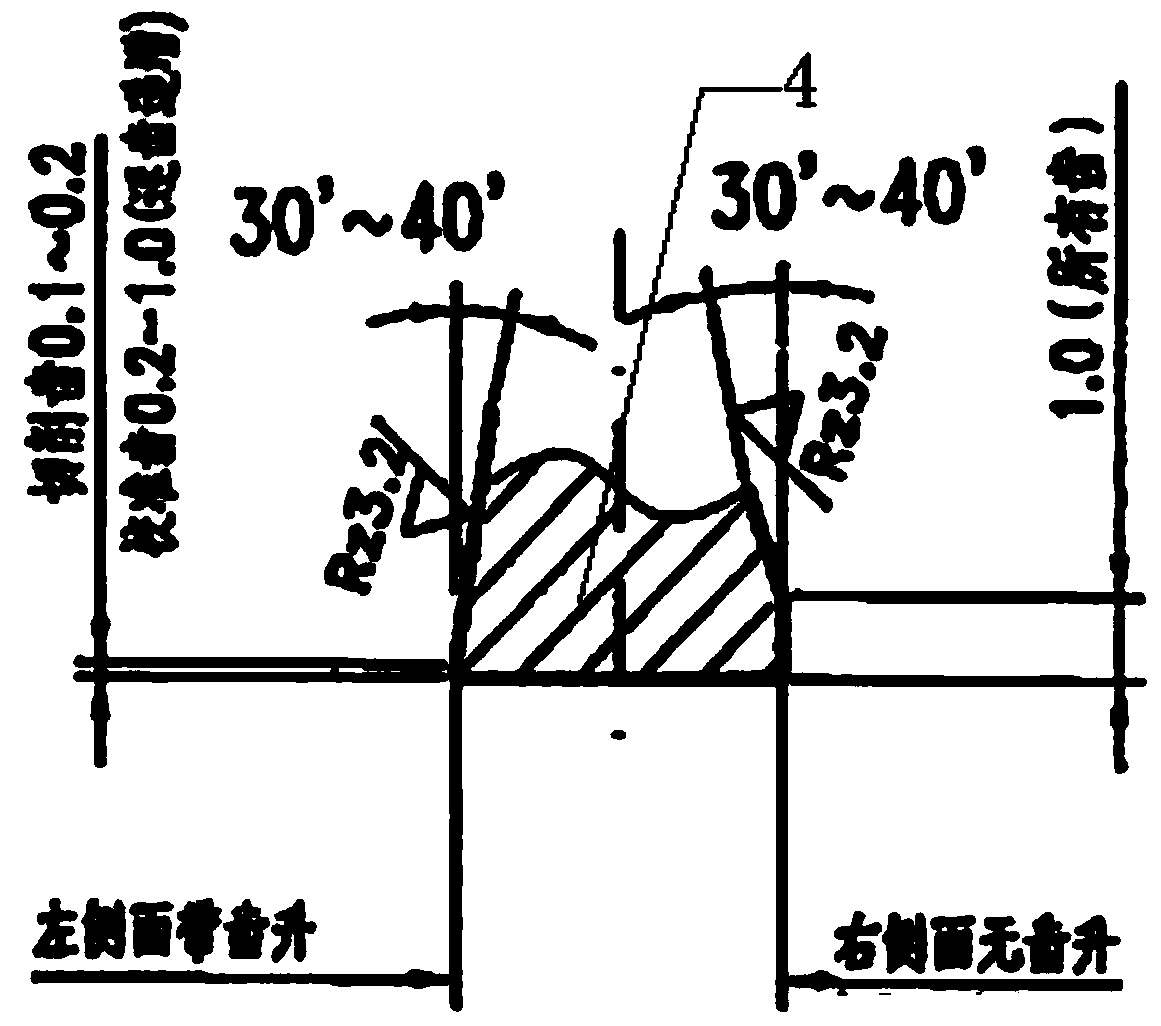

[0015] Such as Figure 1 to Figure 3 As shown, a single-side broaching involute internal spline deburring broach is characterized in that it includes a front handle 1, a transition cone 2, a guide key 3, a spline cutting tooth 4, and a spline shaping tooth 5 connected in sequence , scalloped portion 6, rear handle 7, the guide key, the spline cutting tooth, and the scalloped portion are linearly connected with the axis; the guide key plays the role of guiding the teeth; the spline cutting tooth plays the role of unilateral broaching and removal The role of edge burrs; the scalloped part plays the role of shaping and finishing; the spline cutting teeth include a plurality of identical spline teeth; the spline teeth include left and right sides; broaching teeth, the blade inclination angle is 30-40°, the cutting tooth margin on the left side is 0.1-0.2; The positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com