Repeating stud welding torch

A stud welding and continuous firing technology, applied in the characteristics of electrodes, welding equipment, arc welding equipment, etc., can solve the problems of low efficiency, high work intensity, and tired fingers of the operator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

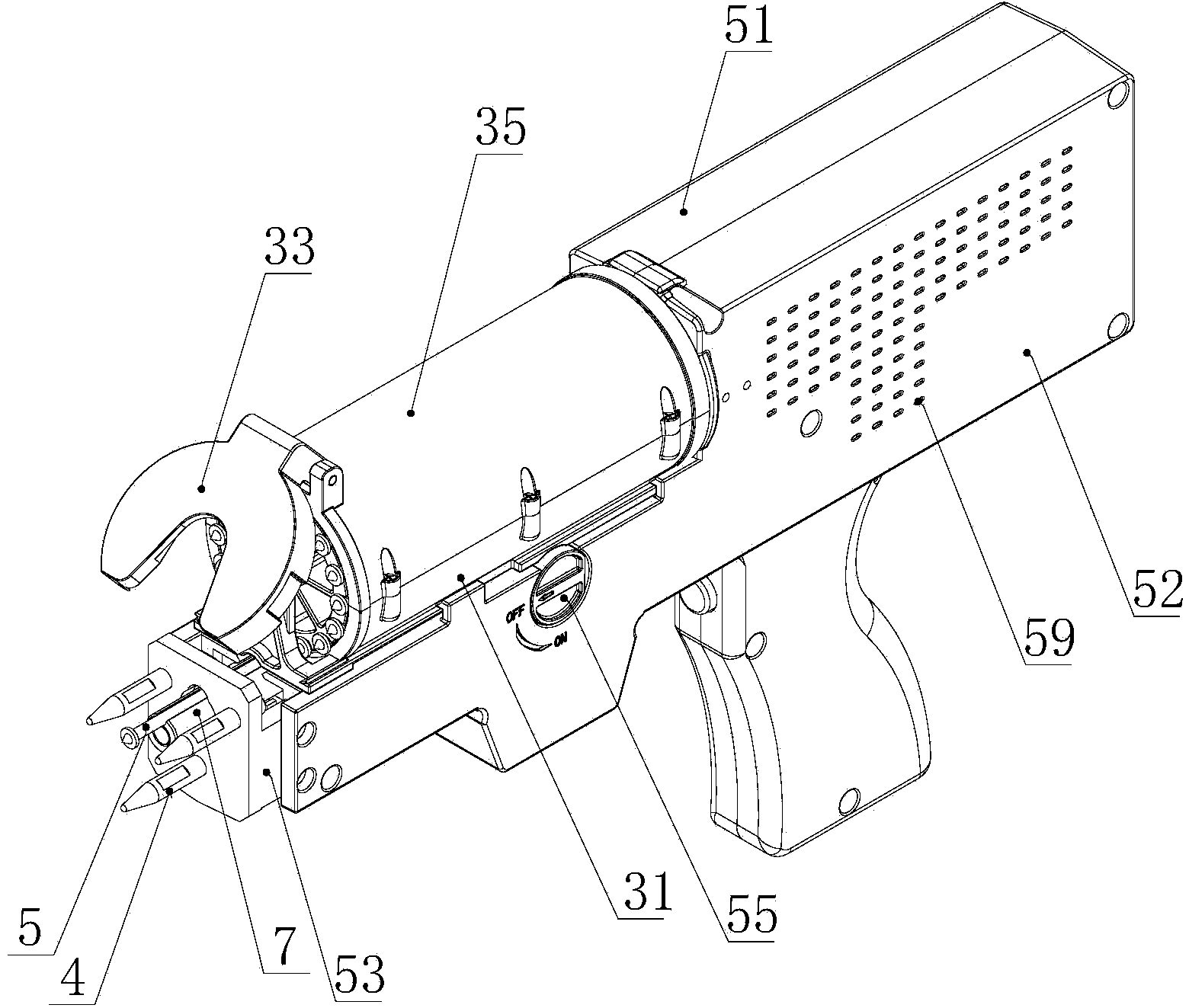

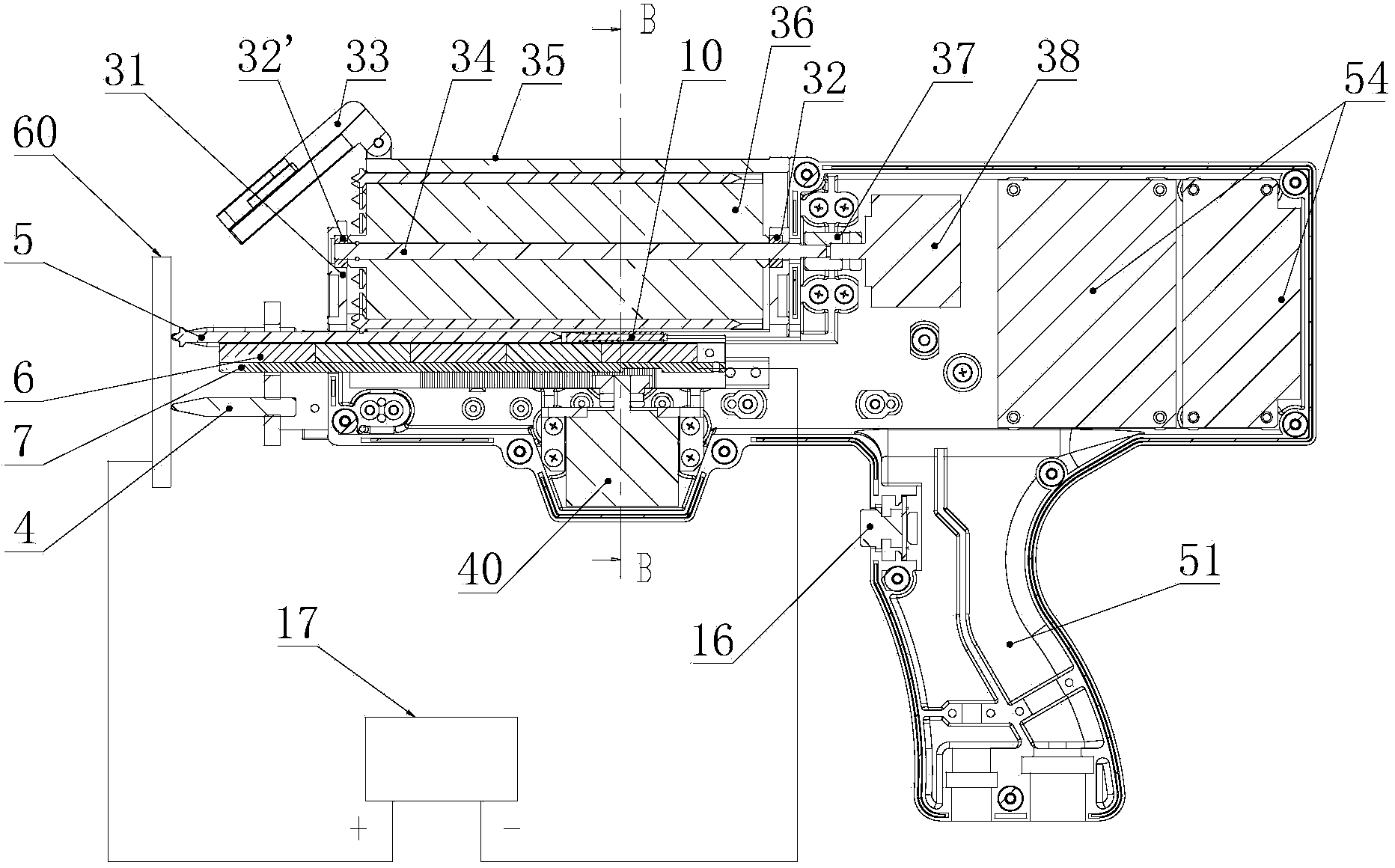

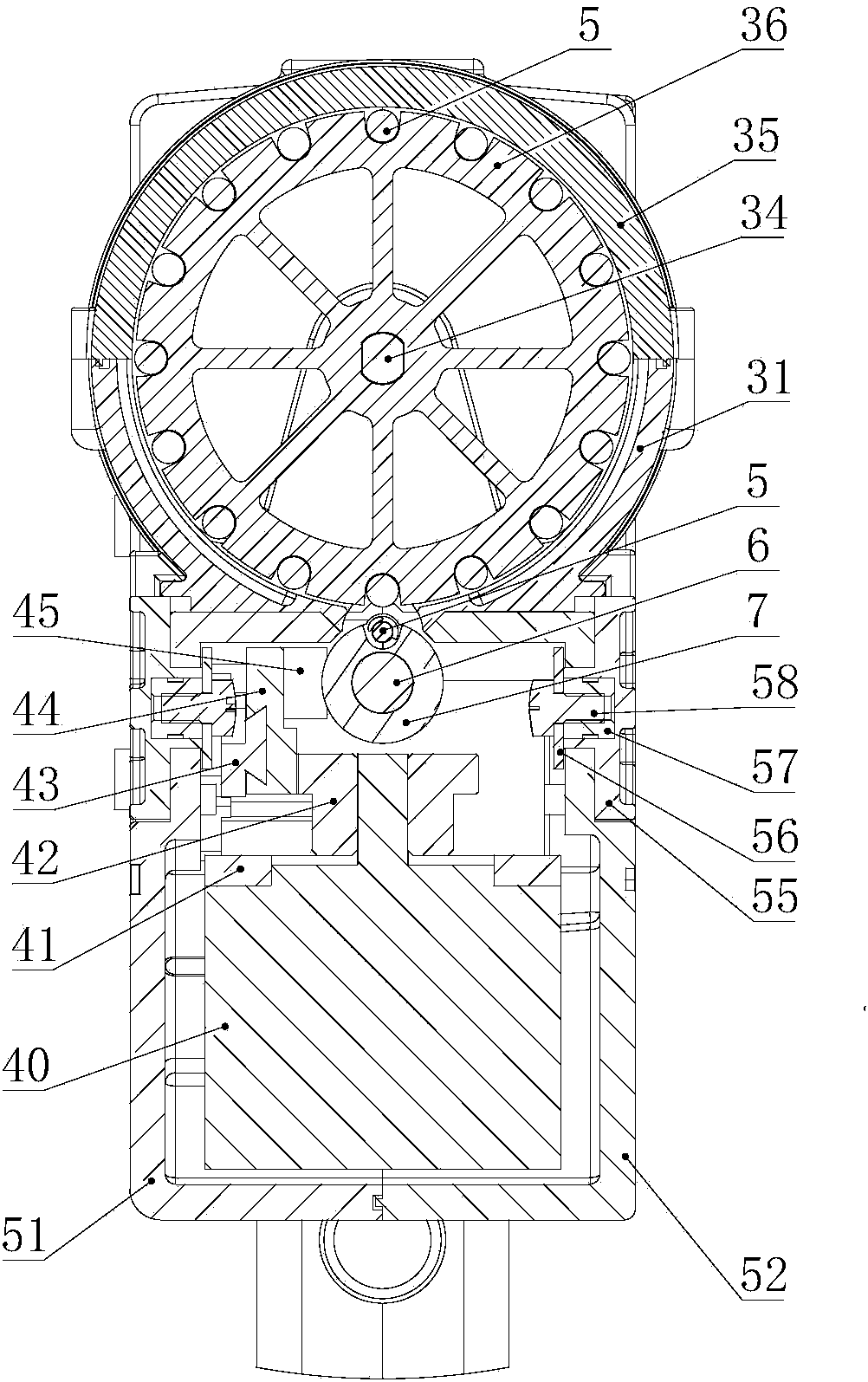

[0023] According to attached Figures 1 to 3 The specific embodiment of the present invention is described further:

[0024] A continuous firing stud welding torch includes a torch casing, a wheel mechanism, a first motor 38 , a second motor 40 , and a driven shaft 7 . The driven shaft 7 is wrapped with a radial magnetic steel 6, and the upper part of the driven shaft 7 is provided with a groove matching the diameter of the welding stud 5. The second motor 40 is fixedly connected with the gun housing through the motor base 41, and the output shaft of the second motor is sleeved with a gear 42, the gear 42 meshes with the rack slider 44, and the rack slider 44 is connected to the driven shaft through the connecting block 45. 7 connection, the rack slider and the guide rail 43 are clearance fit. Driven shaft 7, guide rail 43, rack slide block 44 and connection block 45 are all conductors, and guide rail 43 is connected with the negative pole of welding power supply 17, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com