Double-layer plastic film thermal cutting and bonding knife

A technology of plastic film and double-layer film, which is applied in the fields of special knives for double-layer plastic film production and double-layer plastic film heat-cutting knives. It can solve the problems of low production efficiency, high energy consumption, and low output, and achieve convenient operation and improved Production efficiency and work efficiency, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are exemplified, and detailed descriptions are as follows with reference to the accompanying drawings: There is no innovation in software or methods in the present invention.

[0015] see figure 1 and figure 2 :

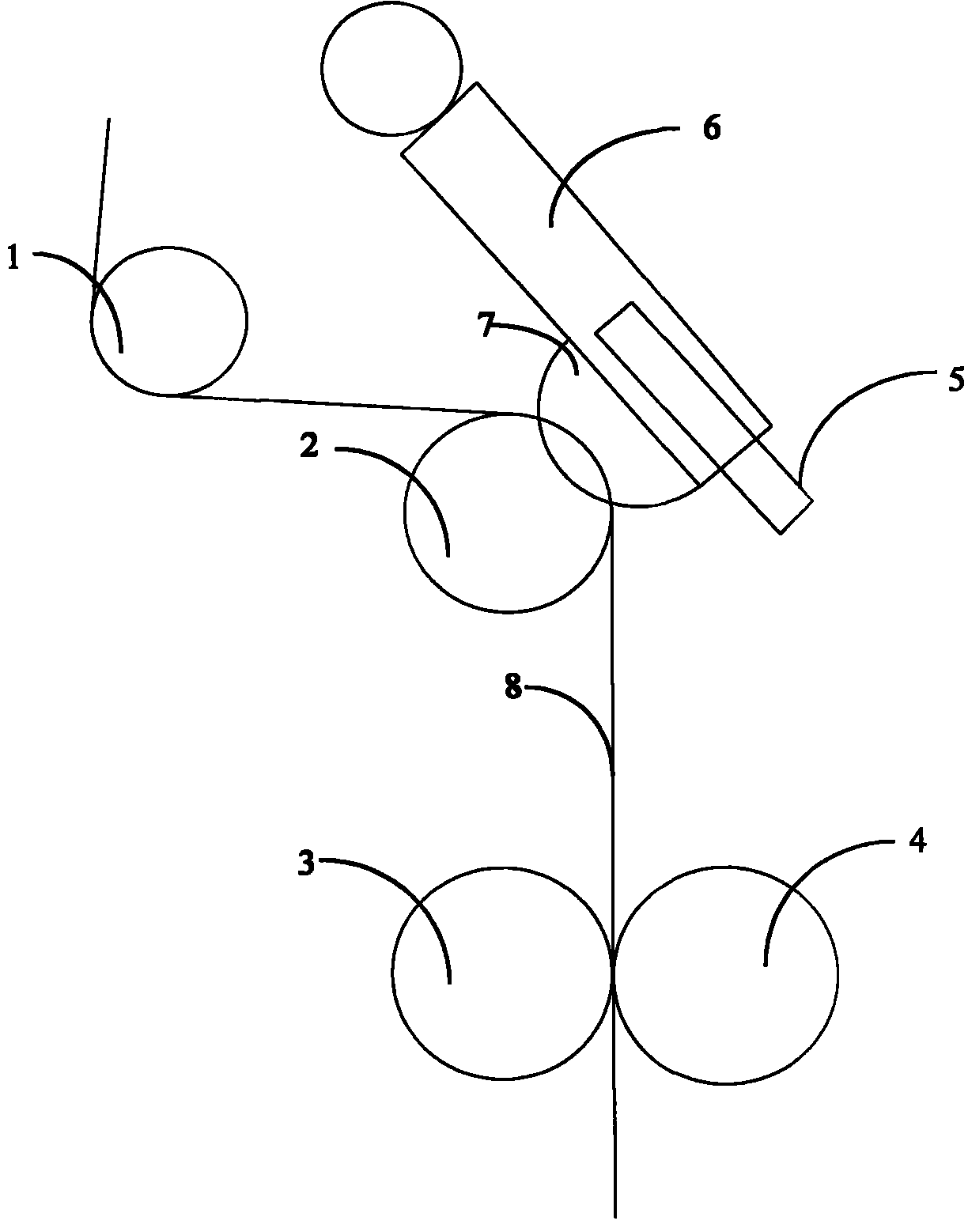

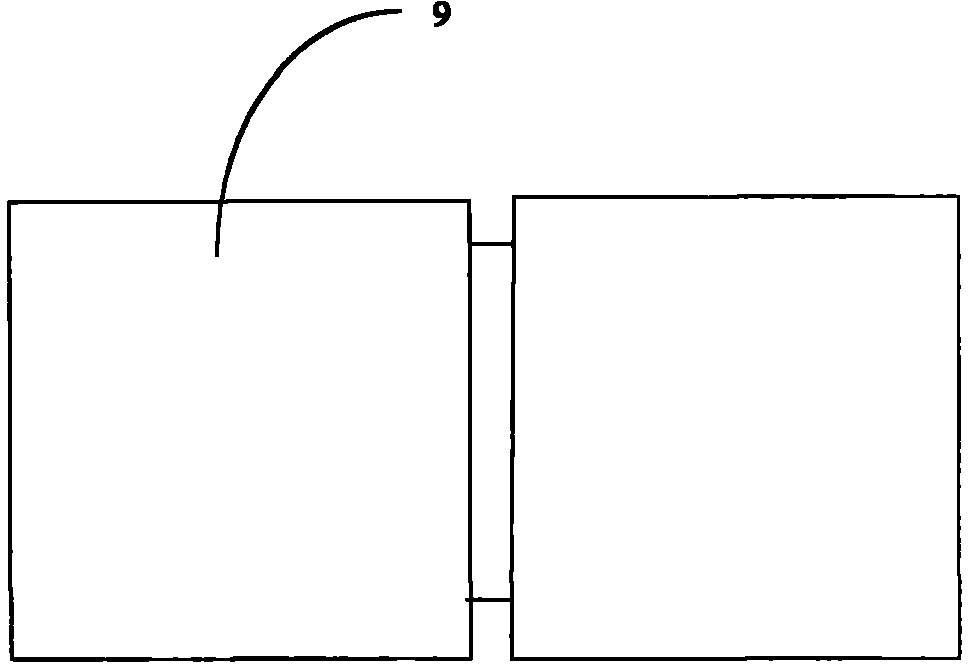

[0016] Such as figure 1 and figure 2 As shown, the double-layer plastic film hot-cutting knife of the embodiment of the present invention is mainly composed of a follow-up rotating roller 1, a rotating bottom knife 2, a traction iron roller 3, a traction rubber roller 4, an electric heating rod 5, a fixed electric heating rod and a blade assembly. It is composed of 6, blade 7, double-layer film 8, and rotating bottom knife box 9;

[0017] The follow-up roller 1 is arranged on the front end of the rotating bottom knife 2, and the fixed electric heating rod and the blade assembly 6 are arranged on the top of the rotating bottom knife ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com