Thermoplastic plastic extrusion strip dedicated head

A thermoplastic and machine head technology, applied in the field of machinery, can solve the problems of large melt flow resistance and uncompact structure of the machine head, and achieve the effects of beautiful appearance, compact structure and flexible disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

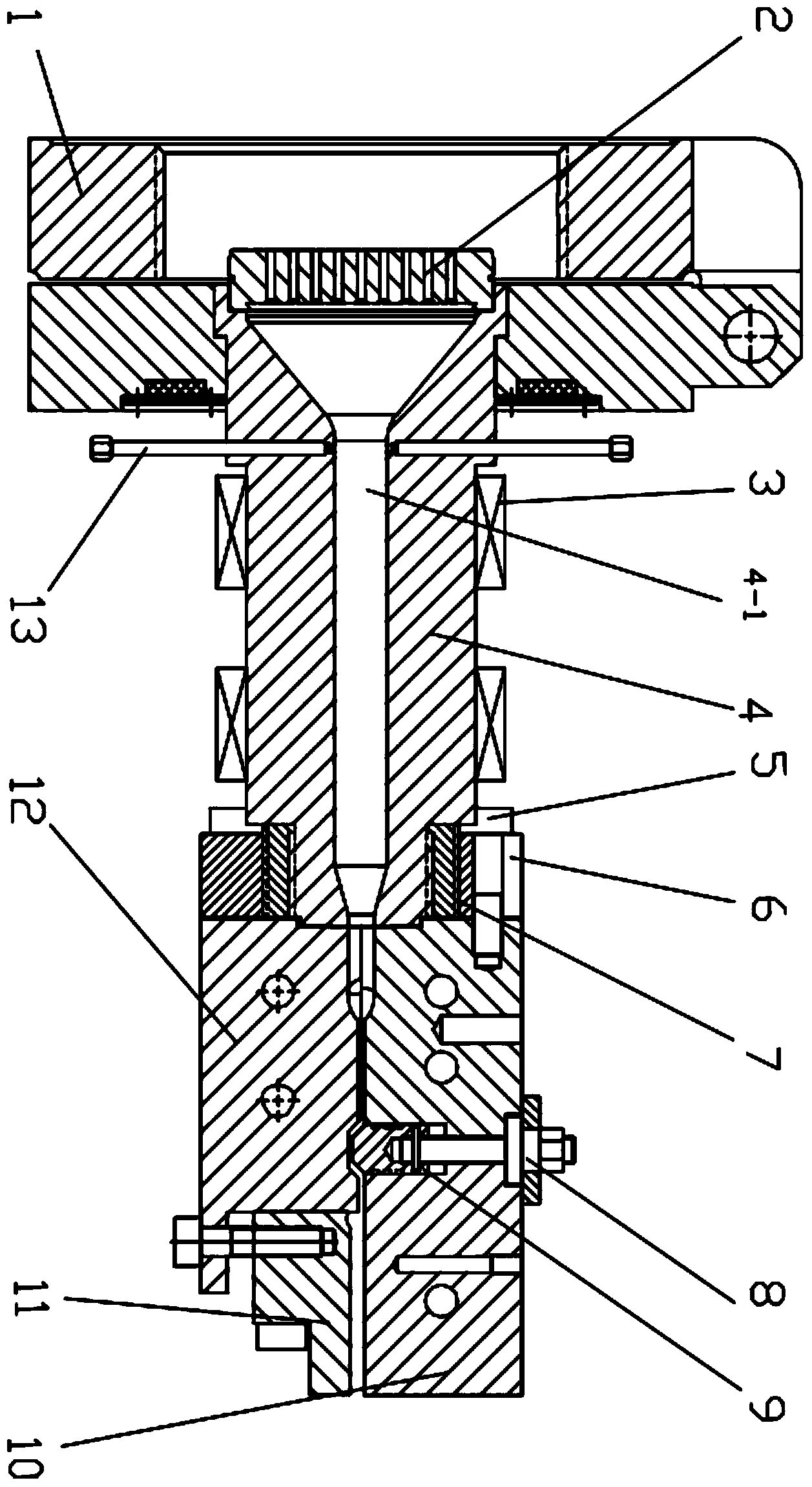

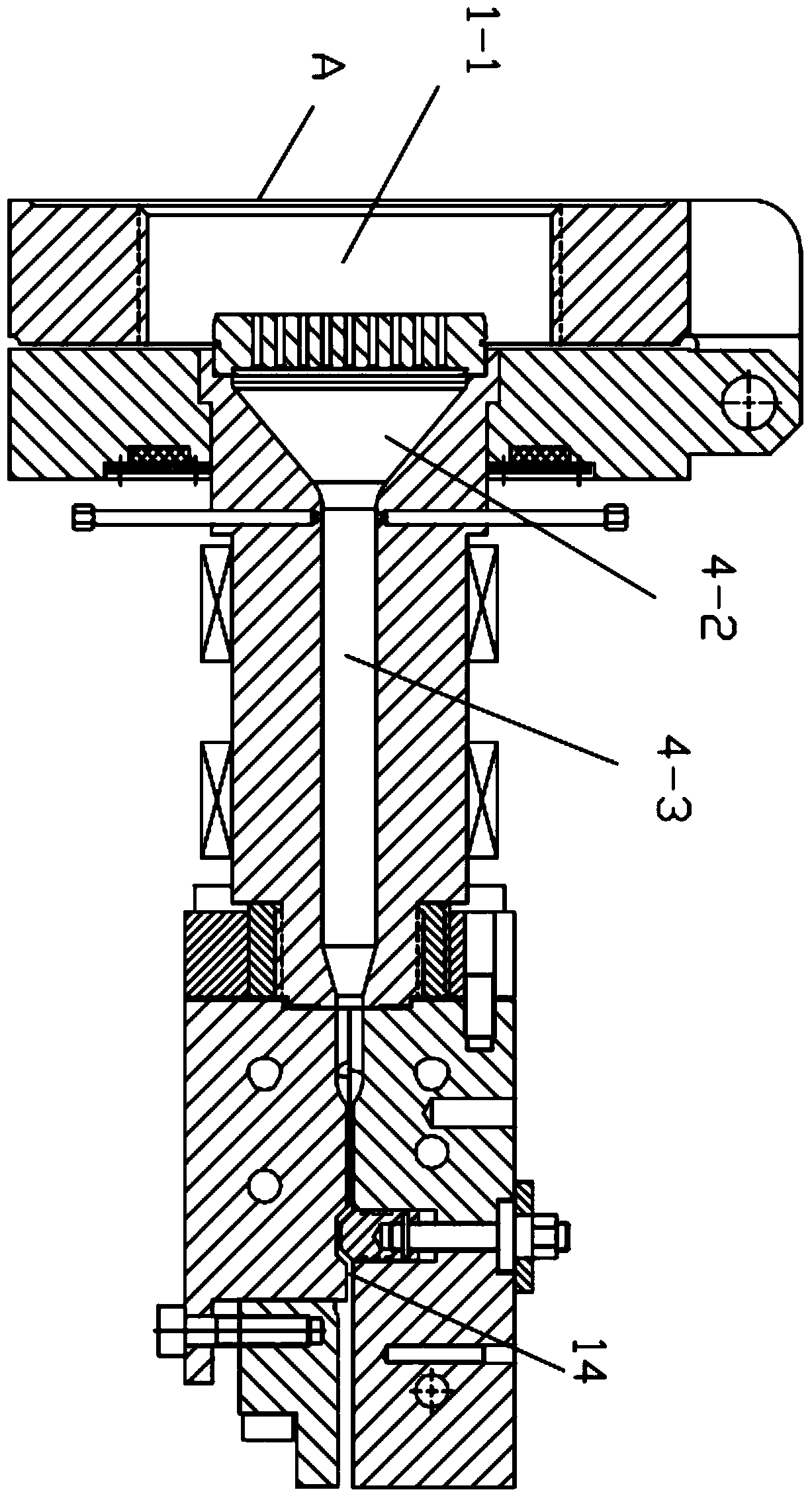

[0018] The present invention will be described in detail below in conjunction with the drawings.

[0019] The special head of the present invention refers to the part between the end of the screw of the extruder and the mouth of the extruder. The special head of the extruder is the key component of the molding of the thermoplastic material. The melt of the extruder is rotated by the screw through the head. The flow state is transformed into a single straight flow state. At the same time, the plastic melt is further plasticized by the temperature control of the heating system, and then the compression ratio is adjusted to generate the required strip molding pressure, which increases the plastic extrusion strip The compactness improves the strength and toughness of the material belt. The continuous material belt with the required rectangular section is obtained through the die, and then wound into a plastic cylindrical tank according to the required diameter.

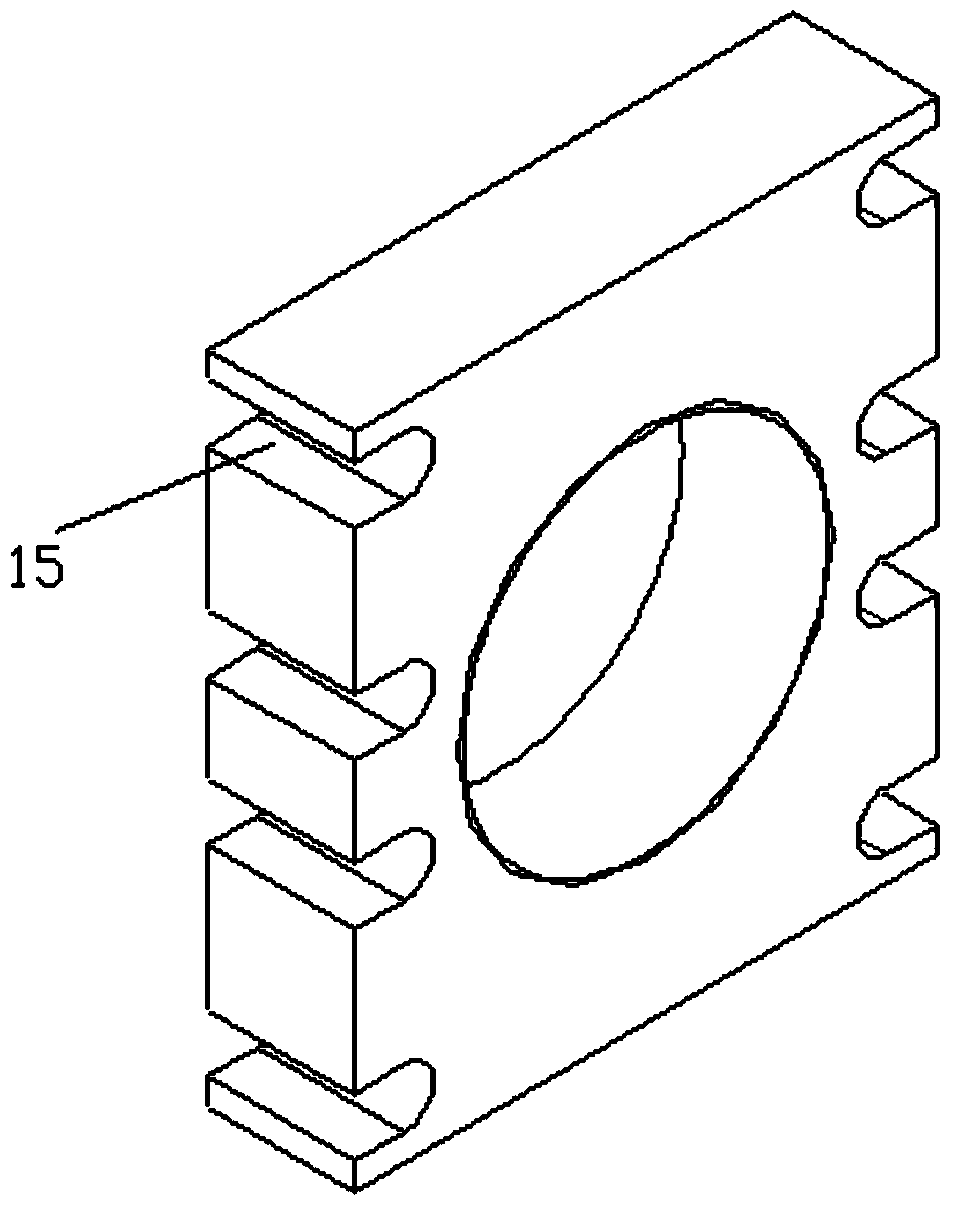

[0020] Specifically, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com