Peristaltic pump type 3D printing pen

A 3D printing pen and peristaltic pump technology, applied in coating preservation and other directions, can solve the problems of single raw material, inflexible use, uneven extrusion speed of raw materials, etc., to achieve a wide range of applications, convenient adjustment and control, and a wide variety of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

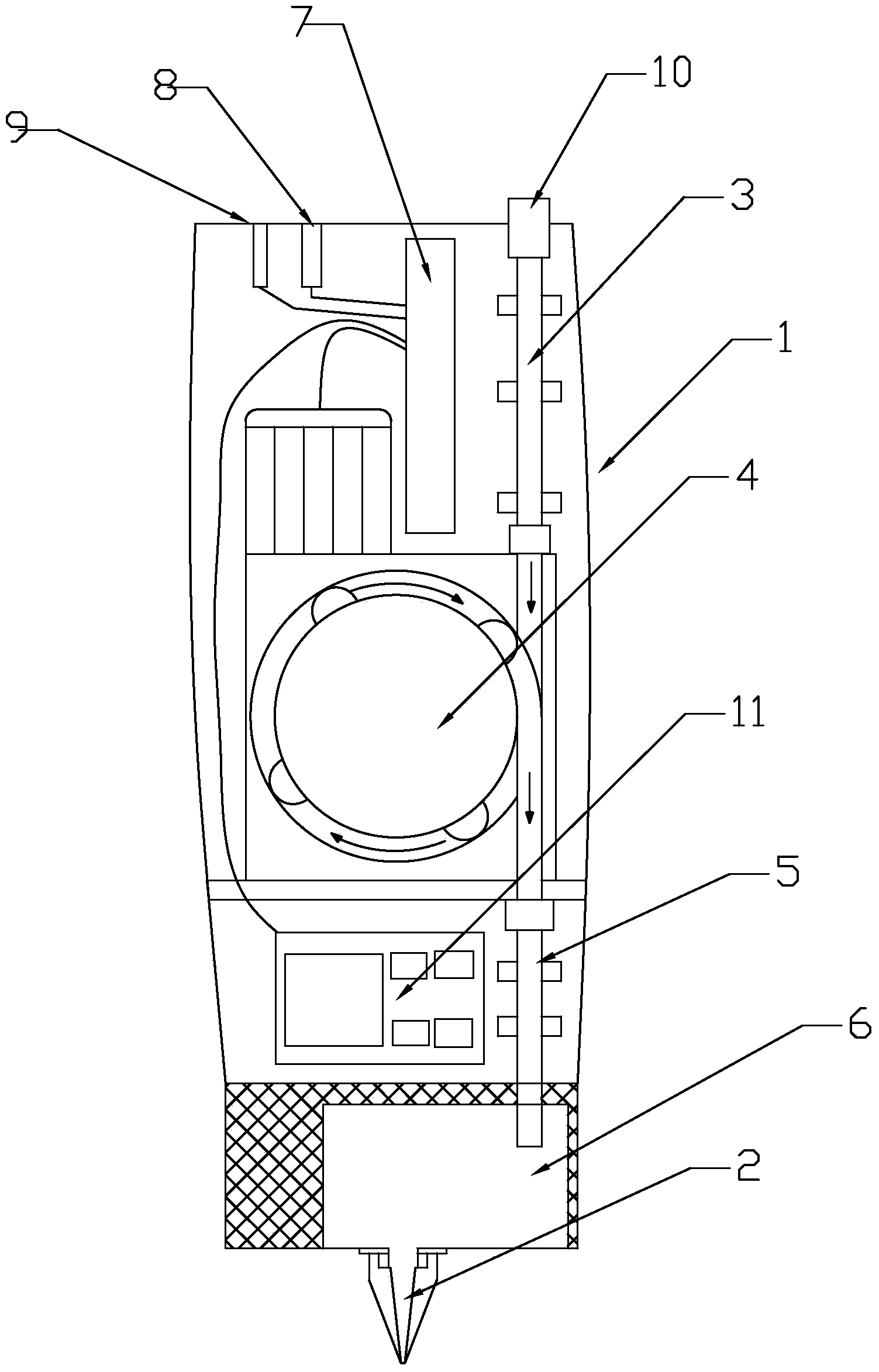

[0016] Such as figure 1 As shown, a peristaltic pump type 3D printing pen includes a pen case 1, a nib 2, a feeding pipe 3, a peristaltic pump 4, a discharge pipe 5, a heat preservation cavity 6, and a circuit module 7; one end of the feeding pipe 3 is provided There is a joint 10 for externally connecting the feeding pipe, and the other end is connected to the input end of the peristaltic pump 4. If the raw material is chocolate, one end of the feeding pipe can be inserted into a heating container for melting chocolate, and the other end is connected to the feeding pipe 3 through the joint 10. The socket can provide a stable source of raw materials for the peristaltic pump type 3D printing pen; one end of the discharge pipe 5 communicates with the heat preservation cavity 6, and the other end communicates with the output end of the peristaltic pump 4, and the discharge The circumferential position of pipe 5 and insulation cavity 6 joint parts is sealed with rubber ring to kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com