Online synchronous film leftover recycling device

A technology of recycling device and rewinding device, which is applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of increased mechanical wear, uneven force, and no improvement of film utilization rate, and achieves improved utilization. The effect of synchronization of production rate and production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

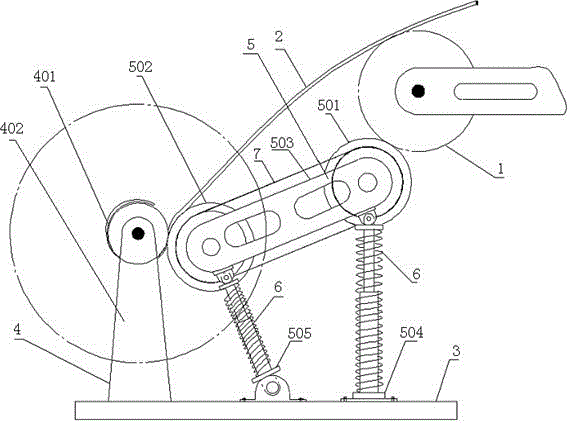

[0031] Both the active wheel bracket 504 and the driven wheel bracket 505 are liftable brackets, the bottom of the active wheel bracket 504 is fixedly connected to the base 3, and the bottom of the driven wheel bracket 505 is connected to the bottom of the driven wheel bracket 505. The base 3 is movably connected, and the top of the driven idler bracket 505 is connected with the second end of the idler link 503 .

[0032]The spring 6 includes a first spring and a second spring, the first spring is sleeved on the driving idler bracket 504, the second spring is sleeved on the driven idler bracket 505, and the first spring is sleeved on the driven idler bracket 505. The first ends of the spring and the second spring are fixedly connected with the base 3 respectively, the second end of the first spring is connected with the first end of the said wheel link 503, and the second end of the second spring is connected with the said wheel. The second end of the rod 503 is connected, and...

Embodiment 2

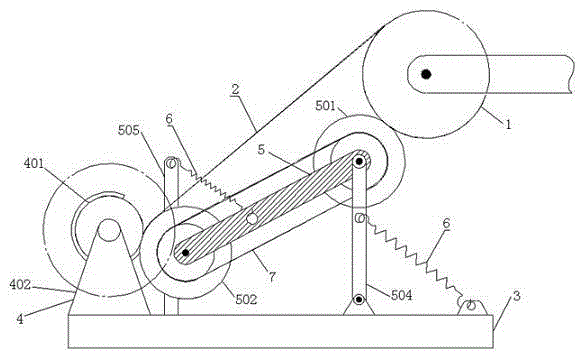

[0035] The bottom of the driving idler bracket 504 is movably connected with the base 3 , and the bottom of the driven idler bracket 505 is fixedly connected with the base 3 .

[0036] The spring 6 includes a first spring and a second spring, the first end of the first spring is connected with the active wheel support 504, and the second end is connected with the base 3; the first end of the second spring is connected with the The said idler link 503 is connected, the second end is connected with the top of the driven idler bracket 505, and the first spring and the second spring are both in tension state.

[0037] The distance from the first end of the first spring to the top of the driving wheel bracket 504 is less than the distance from the first end of the first spring to the bottom of the driving wheel bracket 504; The distance between the driving idler 501 is greater than the distance from the first end of the second spring to the driven idler 502 .

[0038] The distance...

Embodiment 3

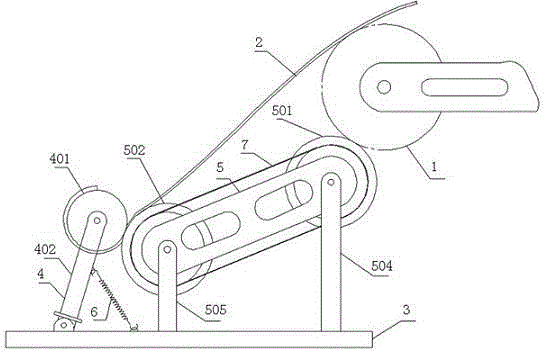

[0041] The bottoms of the driving idler bracket 504 and the driven idler bracket 505 are fixedly connected to the base 3 respectively, and the top of the driven idler bracket 505 is connected with the second end of the idler link 503, so that The bottom of the rewinding shaft support 402 is movably connected to the base 3, the first end of the spring 6 is connected to the rewinding shaft support 402, the second end is connected to the base 3, the first end of the spring 6 is connected to the rewinding shaft support The distance from the top of 402 is smaller than the distance from the first end of the spring 6 to the bottom of the winding shaft support 402, and the spring 6 is in a stretched state.

[0042] Since the bottom of the winding shaft support 402 is movable, the tension of the spring can make the edge of the winding shaft 401 abut against the driven roller 502 .

[0043] The present invention does not need a driving motor, and realizes synchronous recycling of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com