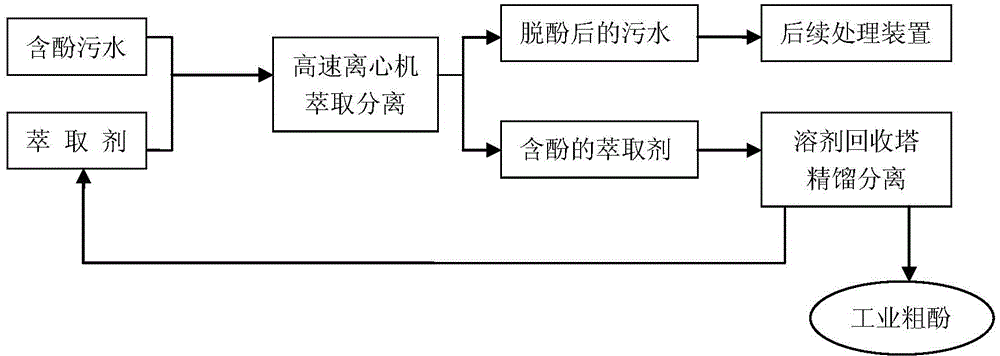

Centrifugal extracting wastewater dephenolization technology

A sewage and extraction technology, applied in the field of environmental engineering, can solve the problems of reducing the added value of phenolic substances, large consumption of acid and alkali, large amount of stripping liquid, etc., and achieves small retention, low solvent loss rate and low operating cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] [Embodiment 1] Adopt the process method of the present invention to process semi-coke production sewage, the main process parameters are as follows:

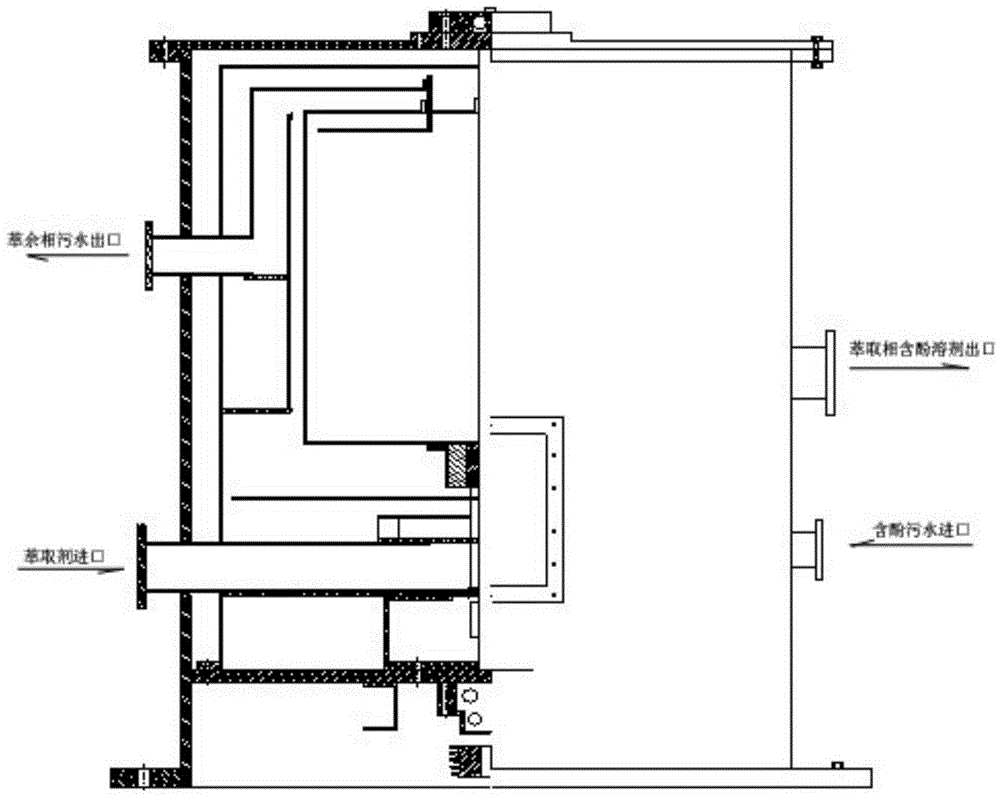

[0040] Main equipment: large centrifuge speed 1500r / min, separation factor 580;

[0041] Sewage treatment capacity: 10m 3 / h;

[0042] Sewage type: semi-coke production (annual output of 600,000 tons) sewage, total phenol content: 8605.6mg / L, volatile phenol content: 4615.8mg / L;

[0043] Solvent type: methyl isobutyl ketone;

[0044] Sewage to solvent volume ratio; 5.5:1;

[0045] Solvent recovery tower top temperature: 98°C;

[0046] Solvent recovery tower bottom temperature: 185°C;

[0047] Reflux ratio: 0.8;

[0048] The total phenol content of treated sewage: 489.2mg / L, volatile phenol content: 268.9mg / L;

[0049] Solvent loss rate: 1.8‰;

[0050] Recovery of industrial crude phenol: 941 kg / day.

Embodiment 2

[0051]Embodiment 2 adopts the processing method of the present invention to process lignite drying dry distillation sewage, according to figure 1 The process shown in the figure is processed, and the main process parameters are as follows:

[0052] Main equipment: large centrifuge speed 1500r / min, separation factor 580;

[0053] Sewage treatment capacity: 8m 3 / h;

[0054] Sewage type: lignite drying (annual output of 600,000 tons) dry distillation sewage, total phenol content: 9236mg / L, volatile phenol content: 5638mg / L, pH value: 8.5, water temperature: 50°C;

[0055] Solvent type: methyl isobutyl ketone;

[0056] Sewage to solvent volume ratio: 6:1;

[0057] Solvent recovery tower top temperature: 102°C;

[0058] Solvent recovery tower bottom temperature: 198°C;

[0059] Reflux ratio: 0.75;

[0060] The total phenol content of treated sewage: 501.2mg / L, volatile phenol content: 319mg / L;

[0061] Solvent loss rate: 1.7‰;

[0062] Recovery of industrial crude phenol:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com