Rolling shutter type low-temperature radiant heating film heating method

A low-temperature radiation, roller-blind technology, applied in the heating field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

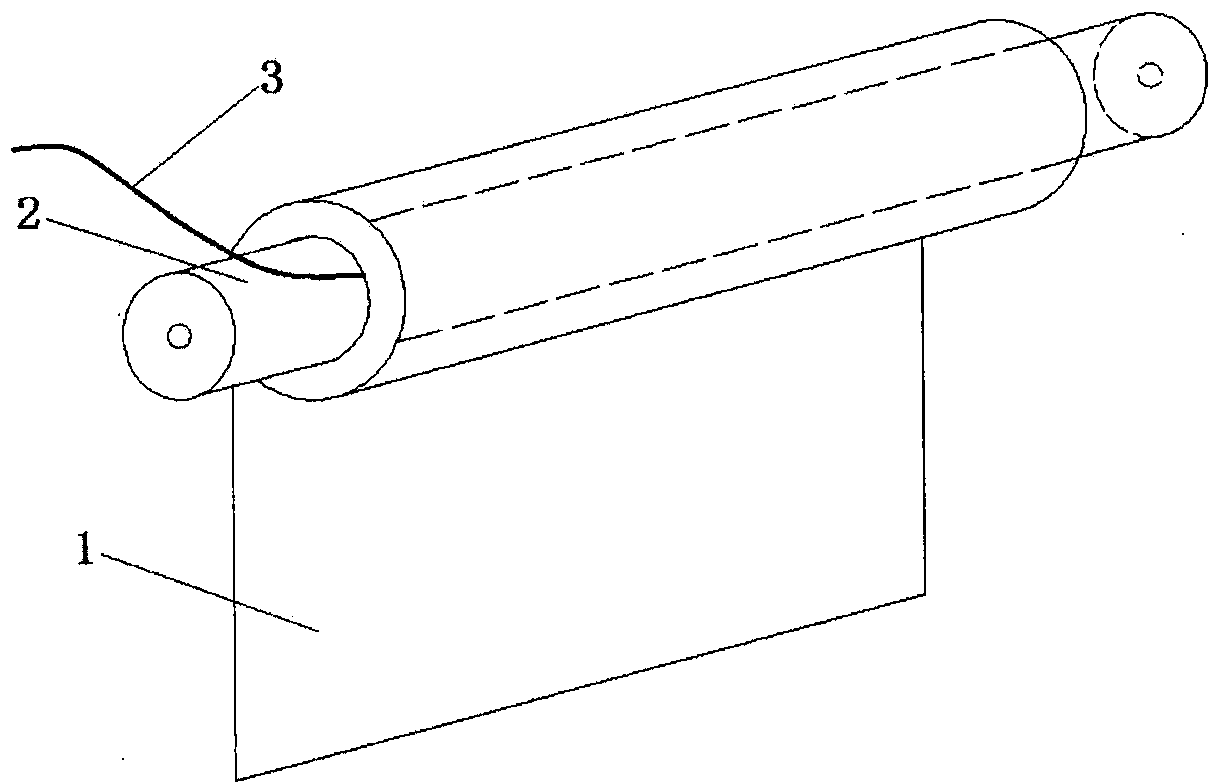

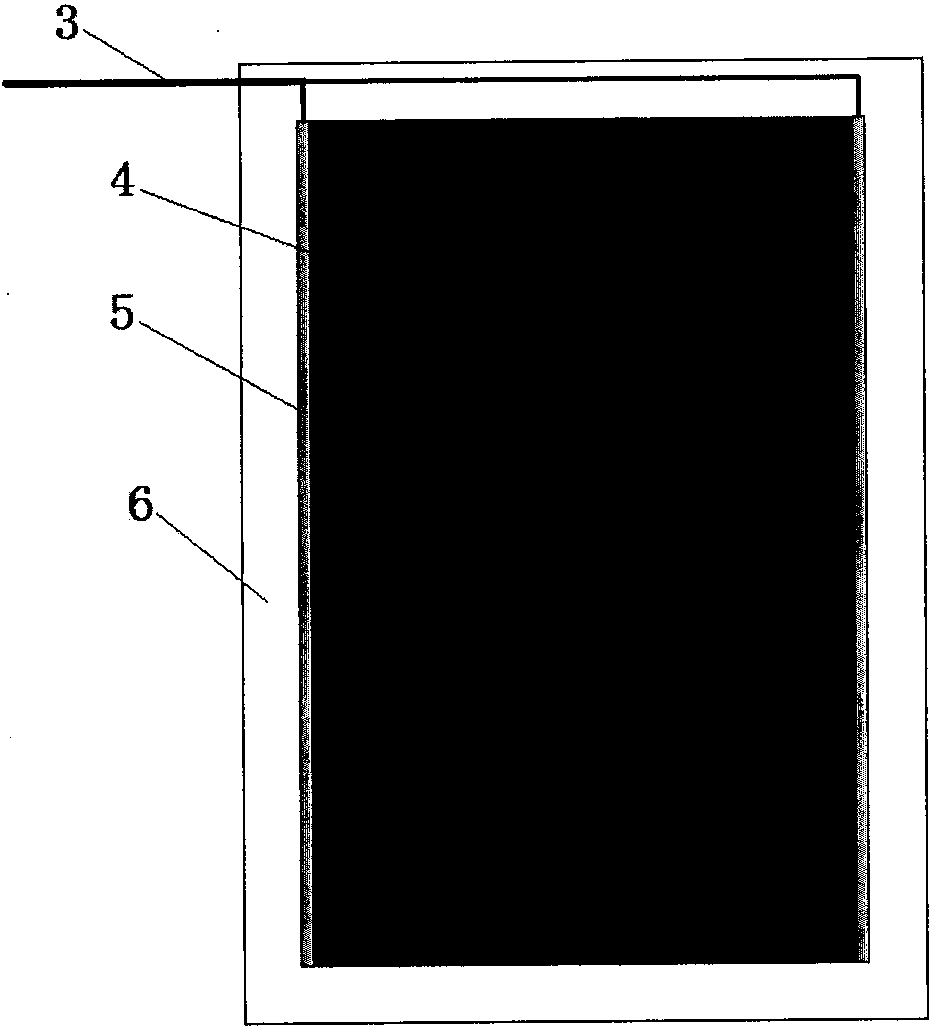

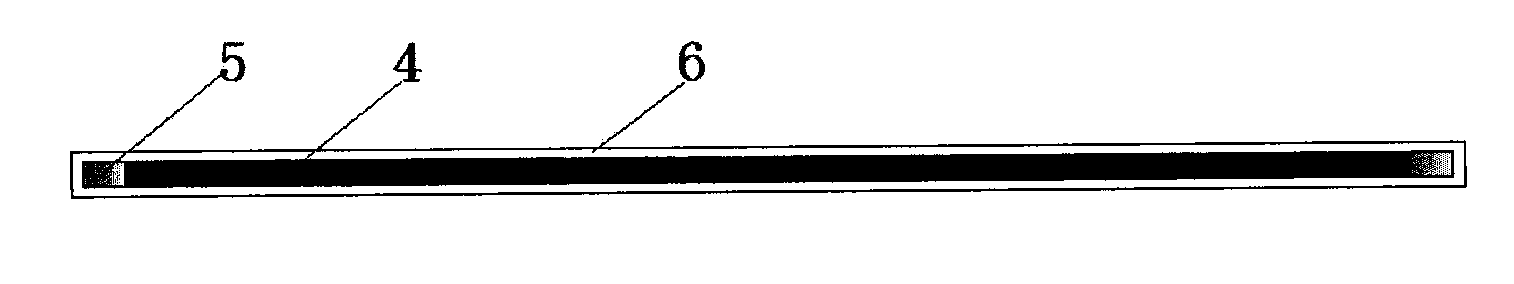

[0016] Such as figure 1 , figure 2 and image 3 As shown, the rolling curtain type low-temperature radiation heating film includes a reel 2, a heating film 1, and the heating film 1 is composed of an electrothermal film 4, an electrode 5 and an insulating sealing film 6; figure 2 and image 3 It can be seen that both ends of the electrothermal film 4 are connected to the electrodes 5 , and the electrodes 5 are connected to the wires 3 and then sealed in the insulating sealing film 6 . The maximum heating power of the electric heating film can be controlled by controlling the amount of conductive filler added, so that electric heating films with different heating power can be selected according to needs. Production method: Add 200g of carbon black particles into 1000g of solvent, ultrasonically disperse evenly, add 1000g of silicone rubber and stir evenly, then add 40g of curing agent; inject the mixed solution into the mold at room temperature for 48 hours to cure and for...

Embodiment 2

[0018] Such as figure 1 , figure 2 and image 3 As shown, the rolling curtain type low-temperature radiation heating film includes a reel 2, a heating film 1, and the heating film 1 is composed of an electrothermal film 4, an electrode 5 and an insulating sealing film 6; figure 2 and image 3 It can be seen that both ends of the electrothermal film 4 are connected to the electrodes 5 , and the electrodes 5 are connected to the wires 3 and then sealed in the insulating sealing film 6 . The maximum heating power of the electric heating film can be controlled by controlling the amount of conductive filler added, so that electric heating films with different heating power can be selected according to needs. Production method: Add 300g of carbon black particles into 1200g of solvent, ultrasonically disperse evenly, add 1000g of silicone rubber and stir evenly, then add 40g of curing agent; inject the mixture into the mold at room temperature for 48 hours to cure and form an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com