Electromagnet test piece work air gap adjusting device applied to micro electromagnetic valve

A technology of working air gap and adjusting device, which is applied in the field of electromagnets, can solve the problems of wearing pads, long test cycle, and prolonging the test cycle, so as to achieve the effects of convenient disassembly and installation, shortening the test cycle, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

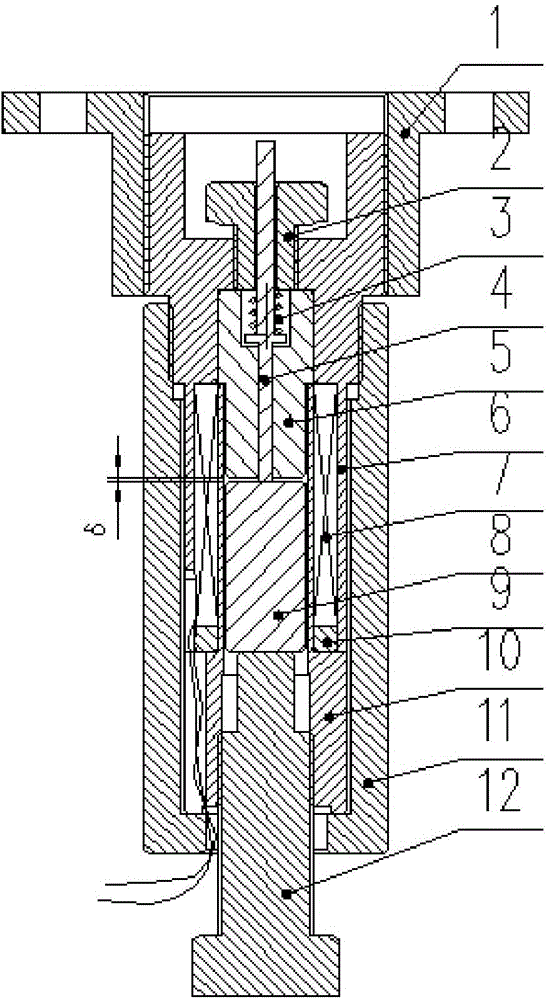

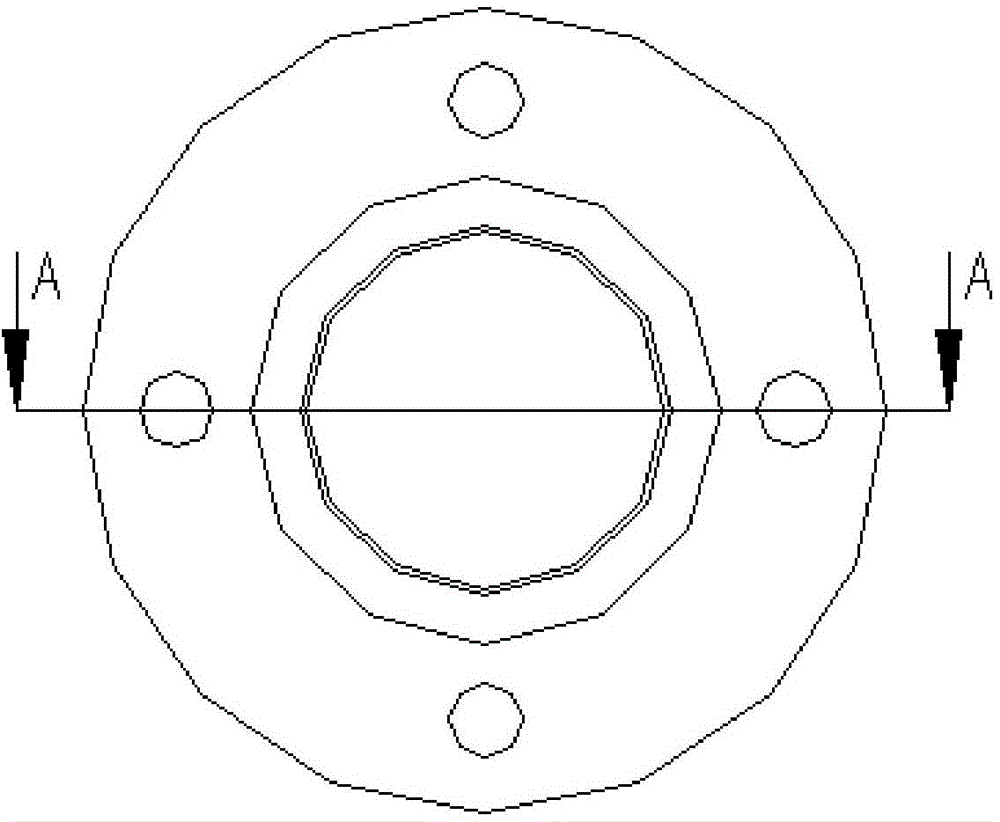

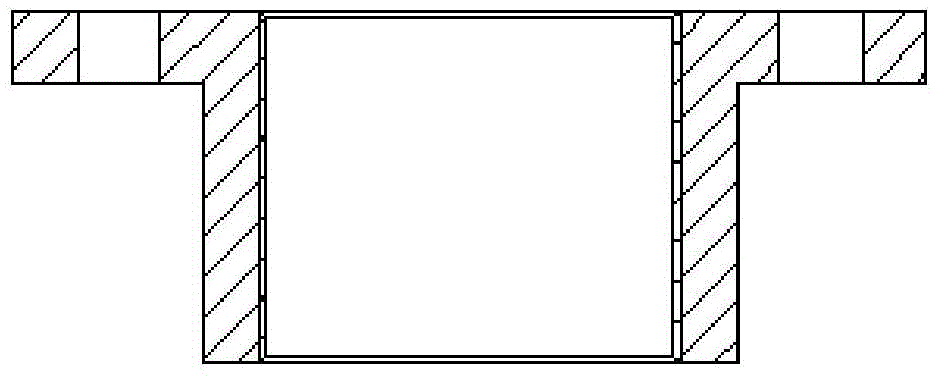

[0026] refer to figure 1 A device for adjusting a working air gap of an electromagnet test piece for a miniature solenoid valve, comprising an electromagnet test piece, a working air gap adjusting mechanism, and a test bench installation and fixing mechanism. The electromagnet test piece includes a thrust rod 4, a preload spring 3, a static iron core 5, an armature 8, a base 10, a coil spacer 9, a coil 7 and an electromagnet jacket 6; the working air gap adjustment structure includes a spring adjustment Bolt 2 and armature adjustment bolt 12; the test bench installation and fixing structure includes coupling sleeve 11 and fixed sleeve 1.

[0027] During the installation process, firstly, the coil spacer 9 is fitted on the base 10 through clearance fit, the coil 7 is wound on the base 10, and two enameled wires are drawn out, and the enameled wire winding thickness is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com