Shaft with a flange connection

A flange and forging technology, which is applied in the field of flange connection devices, can solve the problems of increasing time consumption and achieve the effect of increasing static friction and simple and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

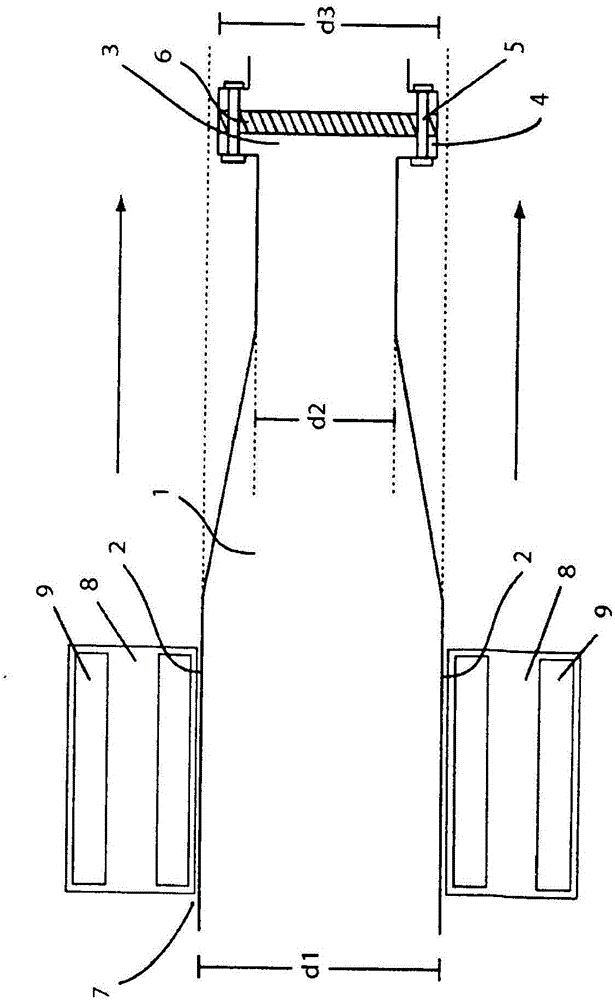

[0017] exist figure 1 shows a shaft 1 which has a diameter d1 at the location of the rolling bearing housing 2 . The shaft 1 tapers conically in the direction of the flange 3 and has a diameter d2 in this narrower region. At the narrower end of the shaft 1 there is a flange 3 with a diameter d3 comprising a flange plate 4 which in this example is forged onto the shaft 1 and is thus integral with said shaft. The flange is connected to the flange piece 4 by screws 5 . In order to transmit the torque, friction discs 6 for evenly distributing the force caused by rotation on the flange discs 4 are installed between the flanges. On the thicker end of the shaft 1 on the hub 7 is mounted a rolling bearing 8 with rolling bodies 9 therein. The diameter d3 of the flange connection 3 is slightly smaller than the inner diameter d1 on which the rolling bearing 8 rests. It is thus possible to remove the rolling bearing 8 on the hub 7 from the shaft in the direction of the arrow after dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com