Light intensity distribution conversion element, surface light source device and liquid crystal display device

一种光强度分布、转换元件的技术,应用在光学元件、光导、光学等方向,能够解决很难得到高均匀性面状光等问题,达到颜色再现范围宽、均匀性优异、简洁结构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

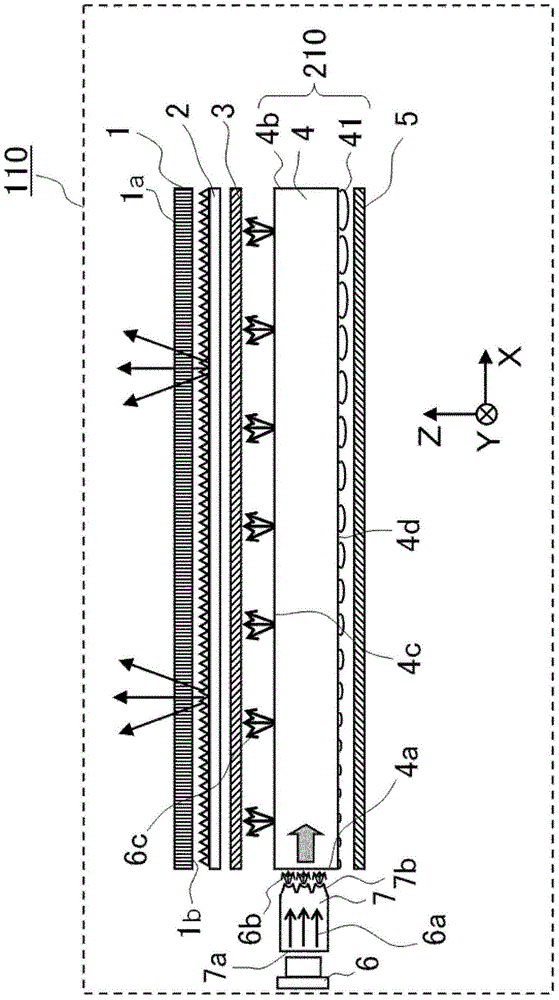

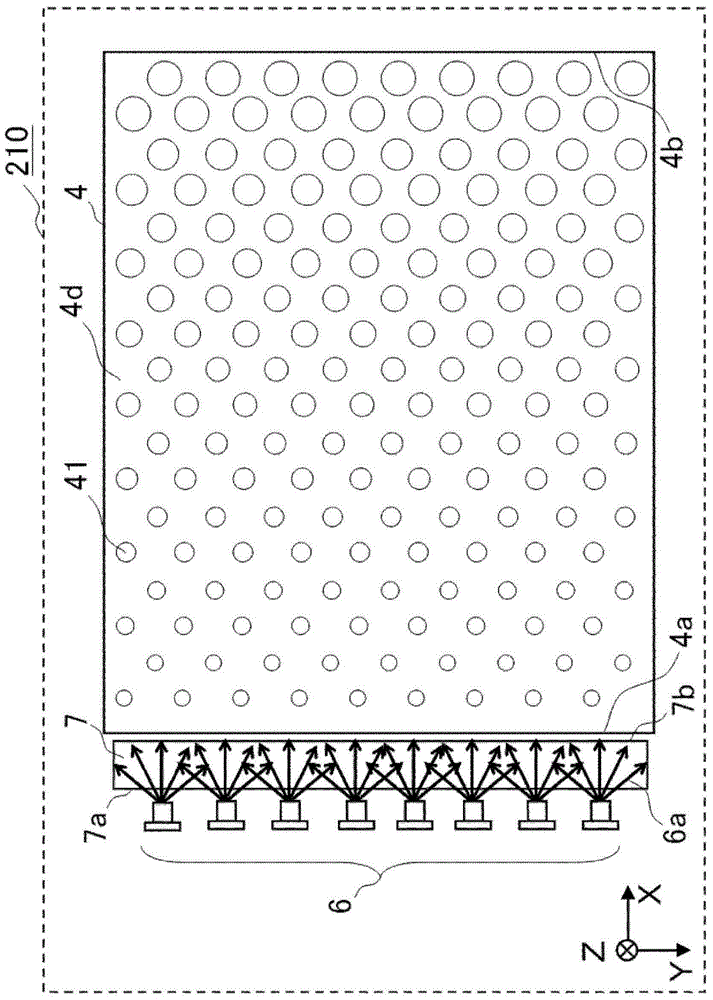

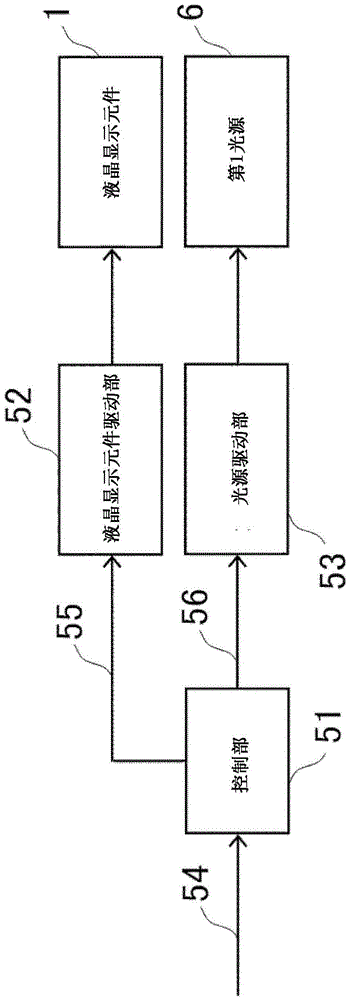

[0039] figure 1 It is a diagram schematically showing the configuration of a liquid crystal display device 110 as a transmissive display device according to Embodiment 1 of the present invention. for easy figure 1 For the description, let the short-side direction of the liquid crystal optical element 1 be the Y-axis direction, let the long-side direction be the X-axis direction, let the direction perpendicular to the X-Y plane be the Z-axis direction, and let the display surface 1a side of the liquid crystal display element 1 be + Z-axis direction. In addition, let the upper direction of the liquid crystal display device be the +Y axis direction, and let the light emission direction of the first light source 6 described later be the +X axis direction. In each of the following figures, when the liquid crystal display device is viewed from the front, the left side is defined as the +X-axis direction.

[0040] Such as figure 1 As shown, the liquid crystal display device 110 h...

Embodiment approach 2

[0092] Figure 12 It is a diagram schematically showing the configuration of a liquid crystal display device 120 as a transmissive display device according to Embodiment 2 of the present invention. The liquid crystal display device 120 of the second embodiment is the same as the liquid crystal display device 110 of the first embodiment except that the surface light source device 220 is different from the surface light source device 210 . That is, the liquid crystal optical element 1 , the optical sheets 2 and 3 , and the light reflection sheet 5 are the same as those of the liquid crystal display device 110 of the first embodiment. The same reference numerals are assigned to the same components as those of the liquid crystal display device 110 described in Embodiment 1, and detailed description thereof will be omitted.

[0093] The surface light source device 220 of Embodiment 2 includes a light source 8 , a light intensity distribution conversion element 9 , and a light guid...

Embodiment approach 3

[0107] Figure 16 It is a diagram schematically showing the configuration of a liquid crystal display device 130 as a transmissive display device according to Embodiment 3 of the present invention. also, Figure 17 It is a configuration diagram showing the surface light source device 230 from the −Z axis direction. In liquid crystal display device 130 of Embodiment 3, surface light source device 230 is different from surface light source device 220 of Embodiment 2 in that it has first light source 10 instead of light source 8 and also has second light source 11 . That is, the liquid crystal optical element 1 , the optical sheets 2 and 3 , the light guide plate 4 , the light reflection sheet 5 , and the light intensity distribution conversion element 9 are the same as those of the liquid crystal display device 120 of the second embodiment. In addition, the components of the liquid crystal display device 120 of the second embodiment that are the same as those of the liquid cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com