Spinosyn/emamectin benzoate microsphere and preparation method thereof

A technology of emamectin and spinosad, which is applied in the field of pesticides to achieve the effect of reducing contact toxicity, reducing harm and improving optical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

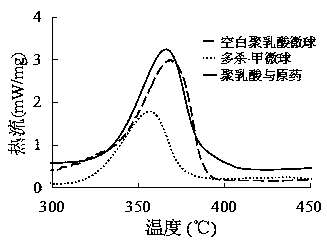

Image

Examples

Embodiment 1

[0036] A preparation method of biodegradable spinosyn / emamectin benzoate microspheres, comprising the following steps:

[0037] (1) Preparation of drug-containing oil-phase suspension: mix 0.7101 g spinosad technical drug, 0.3132 g emamectin benzoate technical drug with 0.765 g polylactic acid, 0.045 g polycaprolactone, 0.09 g stearic acid was mixed, added 10 mL of dichloromethane, and dissolved in an ice-water bath to obtain a medicinal oil phase suspension; wherein, the active ingredient in the original drug of spinosad accounted for 84.5wt%, emamectin benzidine The active ingredients in the salt raw medicine accounted for 95.8%;

[0038] (2) Preparation of primary emulsion: using a high-speed homogenizer, inject the drug-containing oil-phase suspension in step (1) into 100 mL of PVA-1788 aqueous solution under the condition of homogeneous emulsion dispersion, wherein, PVA-1788 The content in the aqueous solution is 20 mg / ml, and the O / W primary emulsion is prepared; the em...

Embodiment 2

[0042] A preparation method of biodegradable spinosyn / emamectin benzoate microspheres, comprising the following steps:

[0043] (1) Preparation of drug-containing oil-phase suspension: mix 0.2034 g spinosad original drug, 0.3760 g emamectin benzoate original drug with 0.425 g polylactic acid, 0.05 g polycaprolactone, 0.025 g stearic acid was mixed, added 10 mL of dichloromethane, and dissolved in an ice-water bath to obtain a medicinal oil phase suspension; wherein, the active ingredient in the original drug of spinosad accounted for 84.5wt%, emamectin benzidine The active ingredients in the salt raw medicine accounted for 95.8%;

[0044] (2) Preparation of primary emulsion: use a high-speed homogenizer to inject the drug-containing oil-phase suspension in step (1) into 200 mL of gelatin aqueous solution under the condition of uniform dispersion of milk, wherein the gelatin in aqueous solution The content is 10 mg / ml, and the O / W primary emulsion is prepared; the emulsificati...

Embodiment 3

[0048] A preparation method of biodegradable spinosyn / emamectin benzoate microspheres, comprising the following steps:

[0049] (1) Preparation of drug-containing oil phase suspension: mix 1.42 g of spinosad original drug, 0.3132 g of emamectin benzoate original drug with 1.05 g of polylactic acid, 0.3 g of polycaprolactone, 0.15 g stearic acid was mixed, added 10 mL of dichloromethane, and dissolved in an ice-water bath to obtain a medicinal oil phase suspension; wherein, the active ingredient in the original drug of spinosad accounted for 84.5wt%, emamectin benzidine The active ingredients in the salt raw medicine accounted for 95.8%;

[0050] (2) Preparation of primary emulsion: using a high-speed homogenizer, inject the drug-containing oil phase suspension in step (1) into 150 mL of PVA-1788 aqueous solution under the condition of homogeneous emulsion dispersion, wherein, PVA-1788 The content in the aqueous solution is 15 mg / ml, and the O / W primary emulsion is prepared; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com