Waste heat distillation drinking device of automotive diesel engine

A technology for diesel engines and drinking water devices, which is applied to engine components, combustion engines, beverage preparation devices, etc., can solve the problems of lack of clean and hygienic drinking water, and achieve the effects of mitigating fire hazards, increasing the heat dissipation area, and increasing the condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

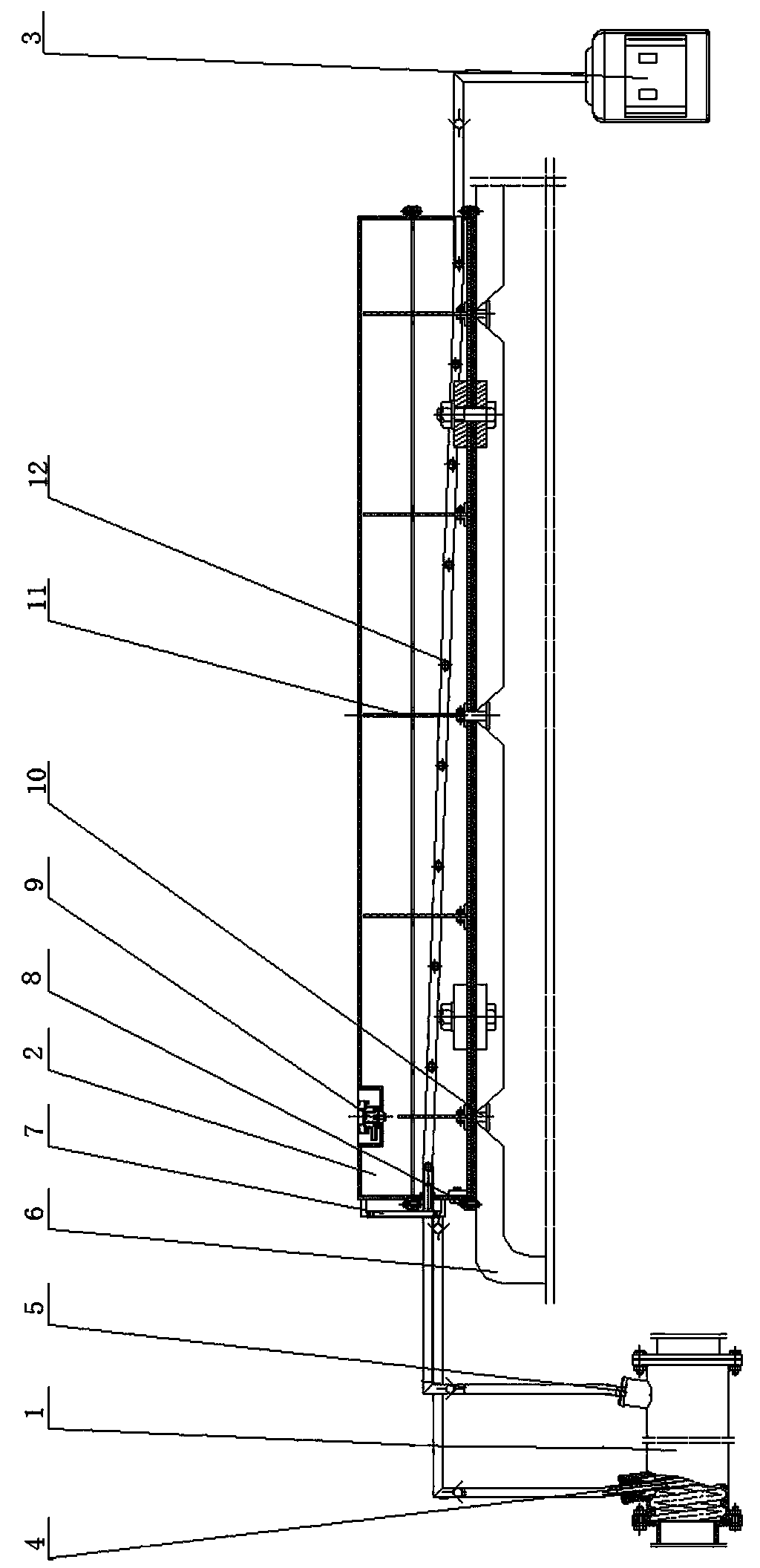

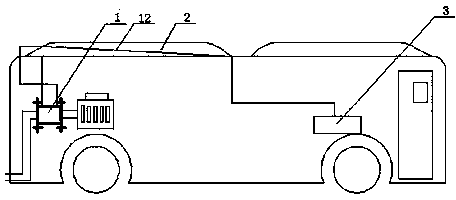

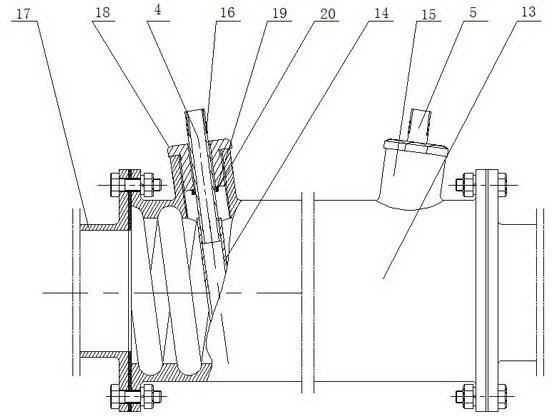

[0022] See Figure 1 to Figure 5 A vehicle diesel engine residual heat distilled drinking water device includes a carburetor 1, a condensed water tank 2 and a water dispenser 3. The carburetor 1 is a key component for the vaporization of the water flowing into the carburetor 1 from the condensed water tank 2 from the liquid state through absorbing the waste heat of the engine to form water vapor, which includes a connecting straight pipe 13 and a spiral pipe 14 . Both ends of the connecting straight pipe 13 are fixedly connected with the original automobile exhaust pipe 17 by bolts. In order to ensure a good vaporization effect, an austenitic stainless steel tube is used to wind a helical tube 14. The inner diameter or small diameter of the helical tube 14 is the same as that of the original exhaust pipe 17, so that it does not aff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com