A well washing and wax removal vehicle and wax removal method thereof

A wax removal vehicle and vehicle body technology, which is applied in the direction of cleaning equipment, earthwork drilling, wellbore/well components, etc., can solve the problems of short warm-up time, warm-up time field, and increased cost, and achieve labor intensity reduction, Long service life, heat loss pin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

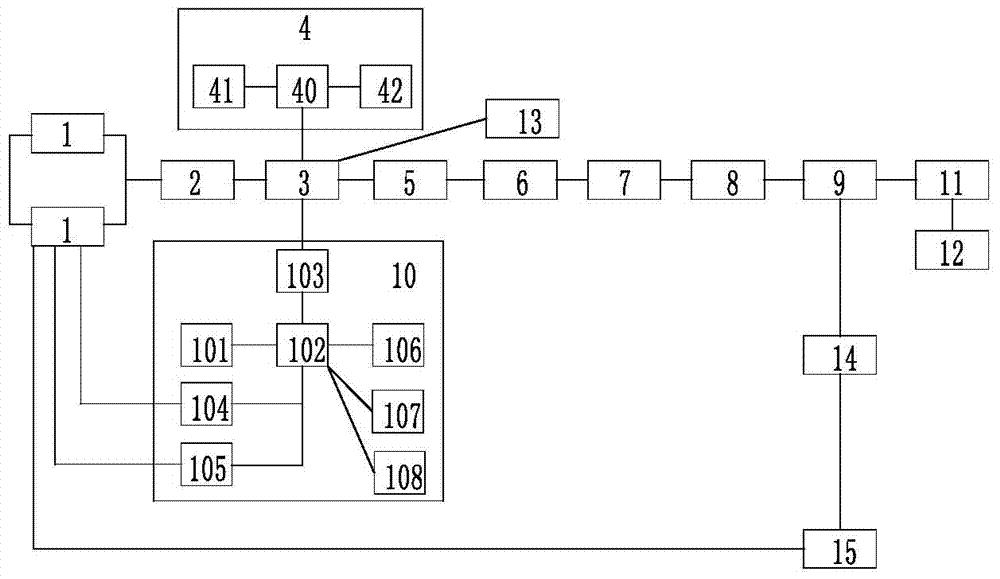

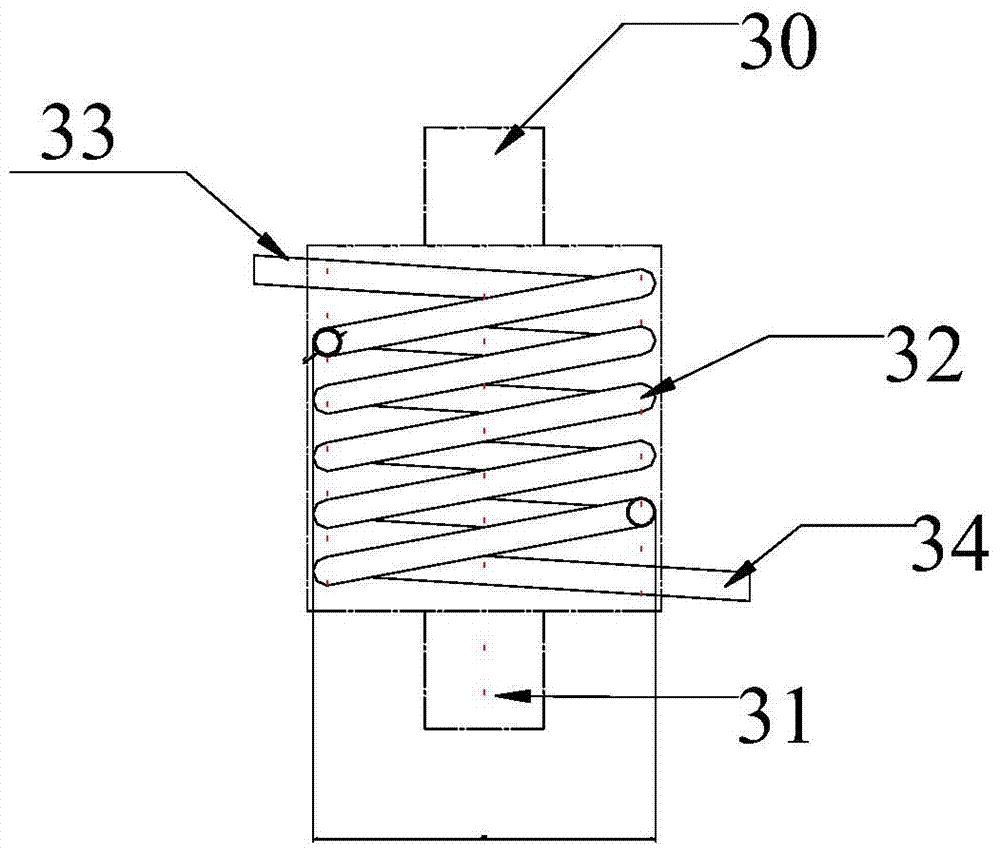

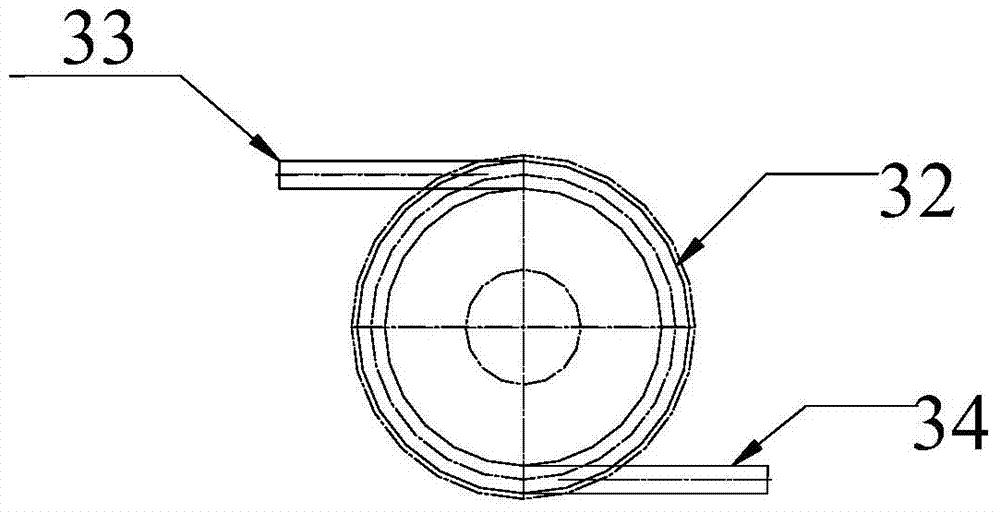

[0025] Attached below Figure 1-4 A well washing and wax removal vehicle and a wax removal method thereof according to the present invention are described in detail.

[0026]An LNG pretreatment device for a well washing and wax removal vehicle, the LNG pretreatment device includes a car body and a box body, the box body is arranged on the chassis of the car body; a plurality of connected LNG Gas tank assembly 1, tail gas collection device 4, vaporization heating system 3, combustion system 11, control system 10 and LNG gas recovery system 12; the LNG gas tank assembly is a double-layer vacuum structure with an inner tank and an outer wall, and the A multi-layer heat insulating material is arranged between the inner tank and the outer wall; the LNG gas tank assembly includes a manual emptying valve for releasing the internal pressure of the gas tank, a liquid filling joint for connecting with a gas dispenser, and a The throttling valve to control the internal pressure of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com