Device and method for pretreating LNG (liquefied natural gas) for well flushing wax removal vehicle

A technology of pretreatment device and wax cleaning car, which is applied to isolation devices, cleaning appliances, earthwork drilling and other directions, can solve the problems of short preheating time, preheating time field and high cost, and achieves reduced labor intensity and long service life. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

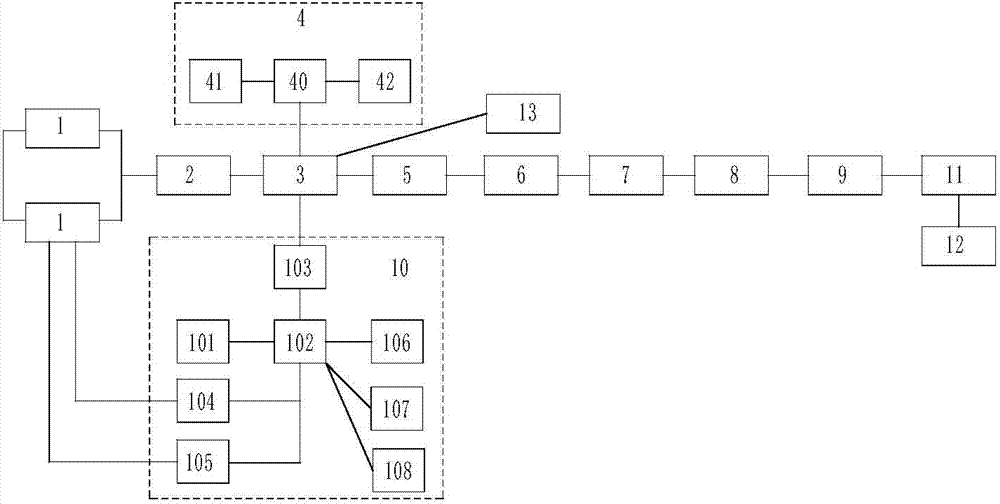

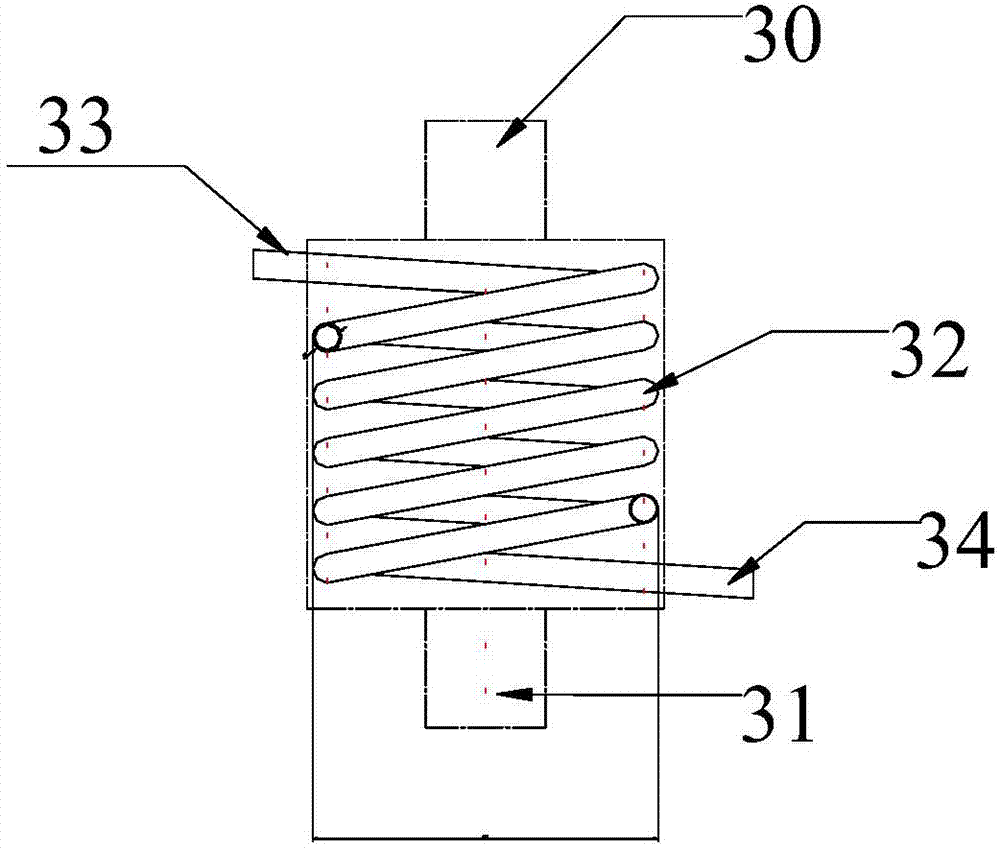

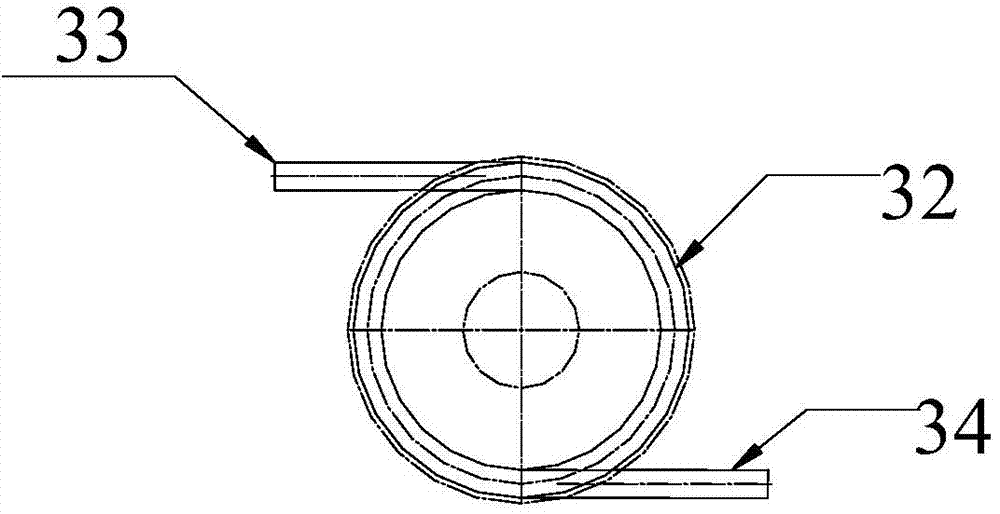

[0022] Attached below Figure 1-3 The LNG pretreatment device for well washing and wax removal truck and its processing method are described in detail.

[0023] An LNG pretreatment device for a well washing and wax removal vehicle. The LNG pretreatment device includes a vehicle body and a box body. The box body is arranged on the chassis of the vehicle body; and the box body is provided with a plurality of connected LNG Gas tank 1, tail gas collection device 4, vaporization heating system 3, combustion system 11, control system 10, and LNG gas recovery system 12; the LNG gas tank and the vaporization heating system are connected through a first-stage pressure reducing valve 2 The vaporization heating system is connected to the combustion system, and a pressure gauge 5, a buffer tank 6, a check valve 7, a secondary pressure reducing valve 8, a pressure gauge 9 are connected in sequence between the two; the exhaust gas collection The device 4 is used to collect the exhaust gas of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com