Edge-folding and ring-cutting machine for bottle caps

A bottle cap and edge cutting technology, applied in metal processing, household components, household appliances, etc., can solve problems such as unfavorable synchronous work, easy loosening of chains, and large space occupied by equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

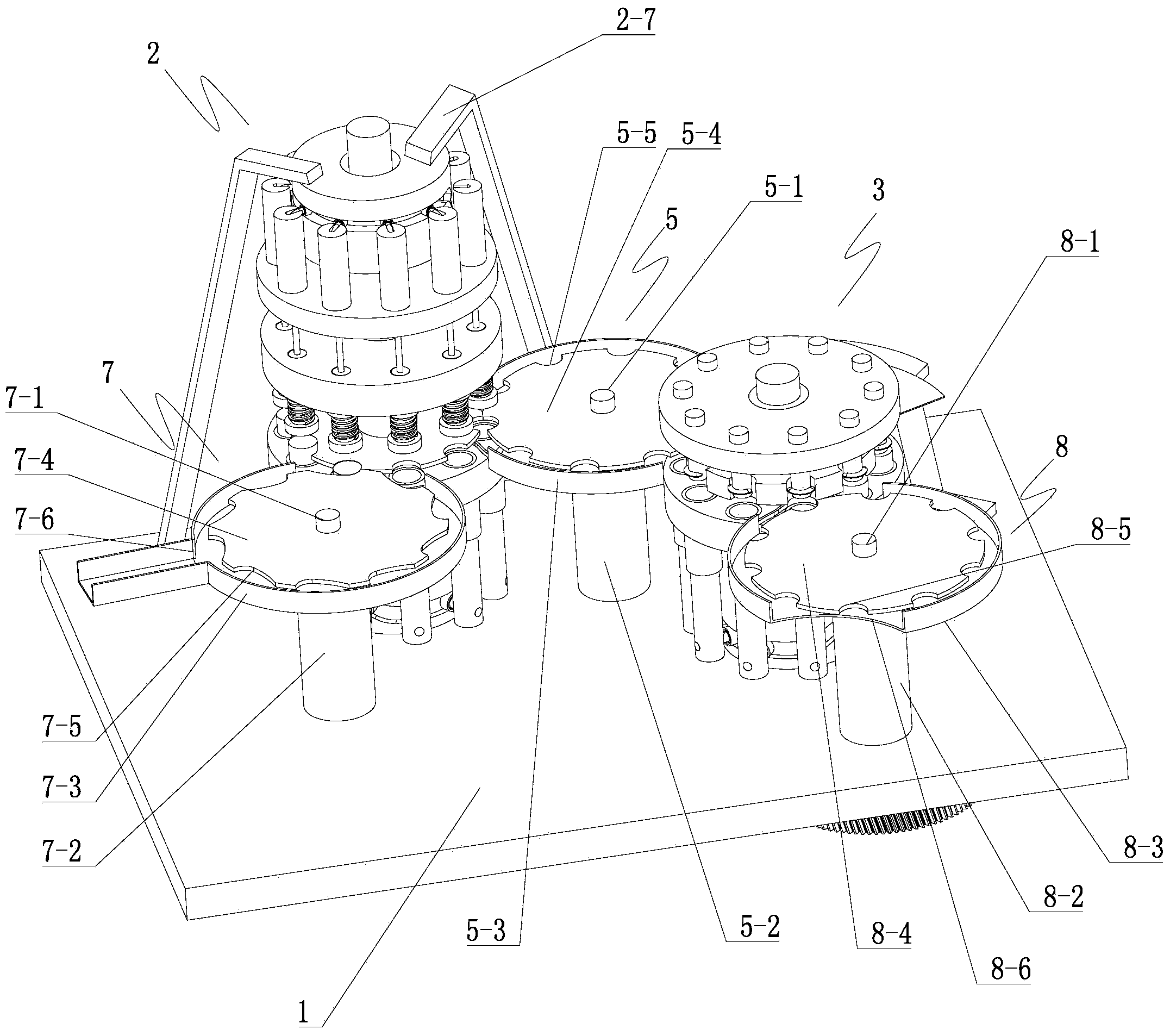

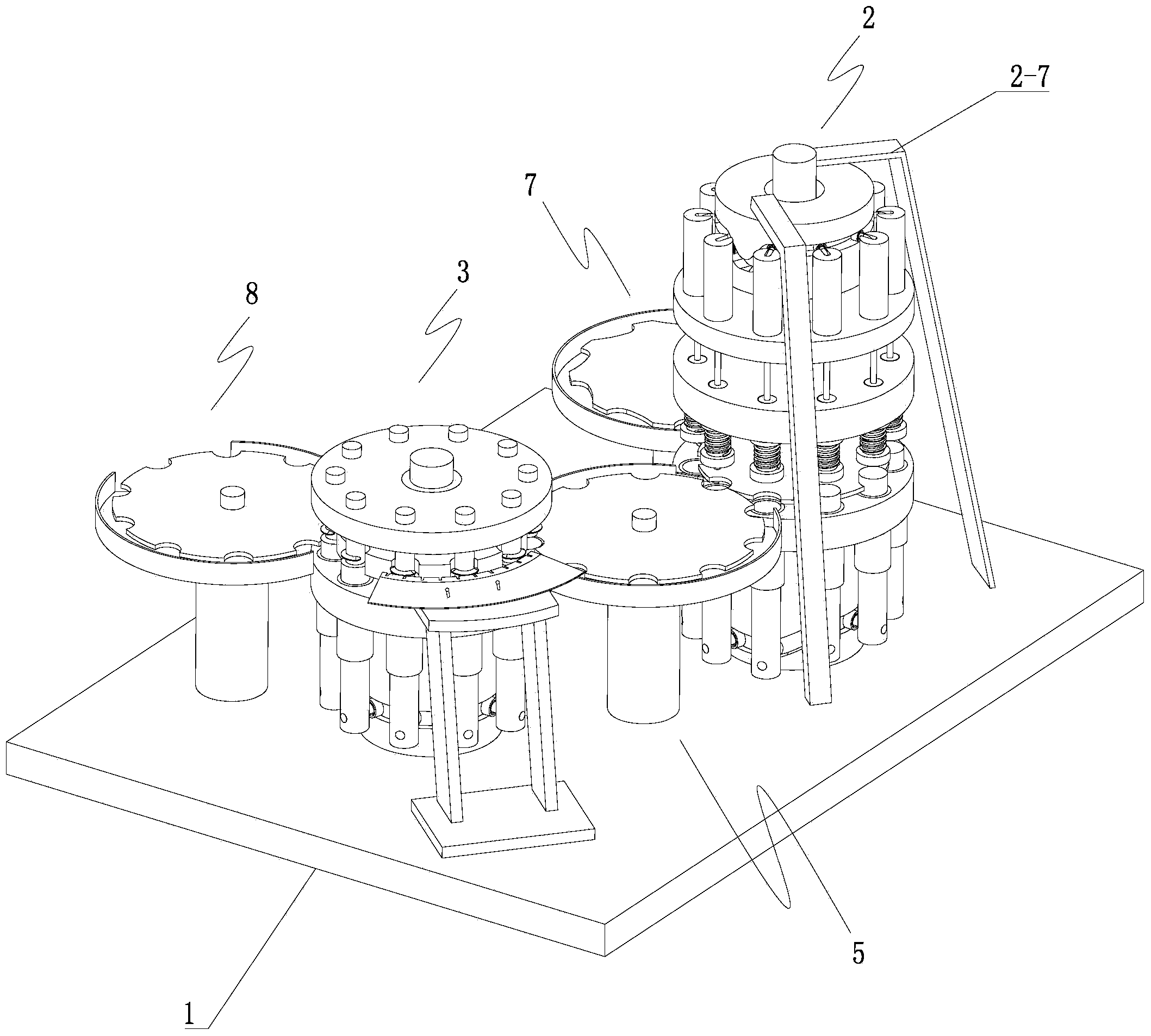

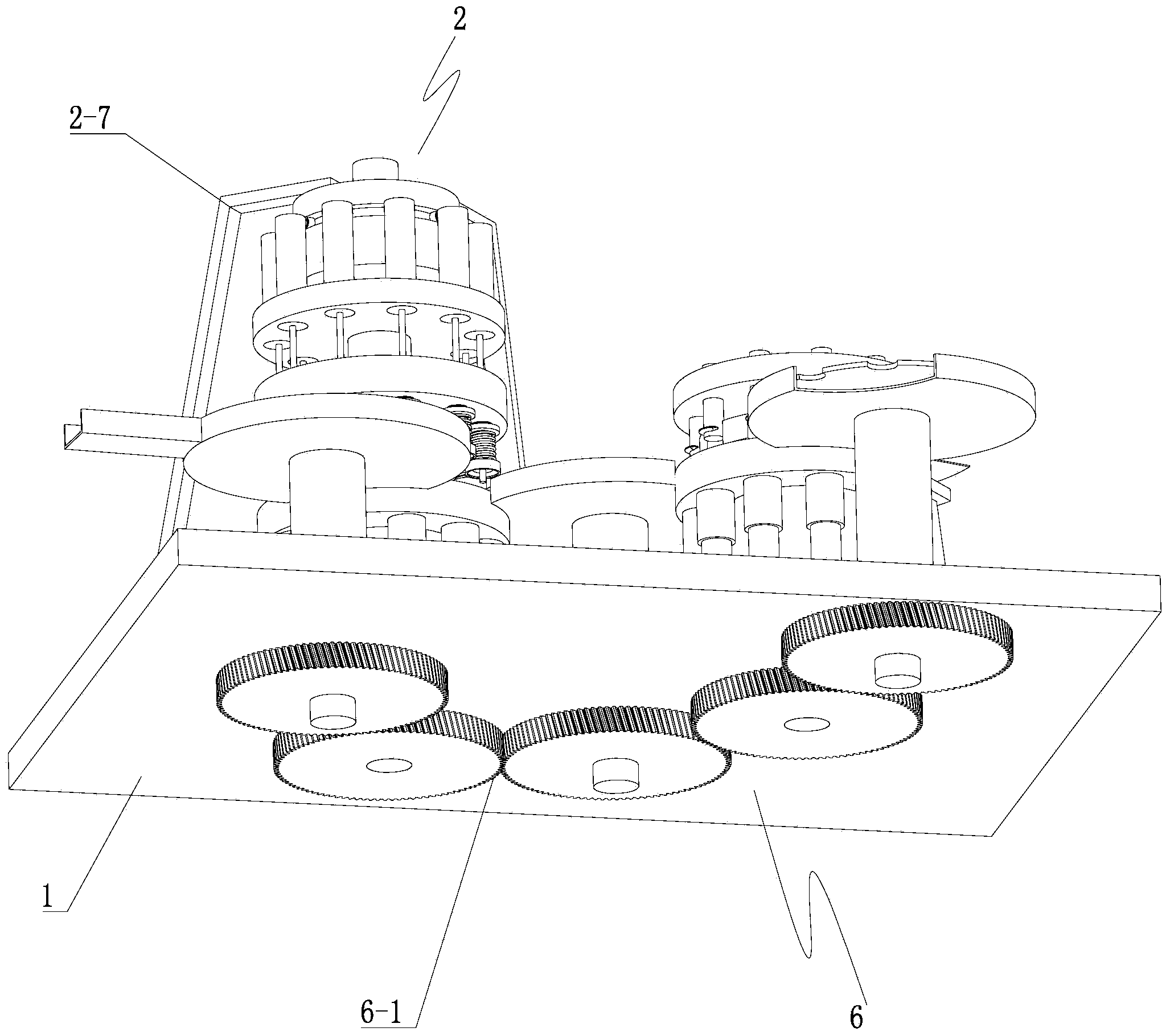

[0028] Such as Figure 1 to Figure 3The shown bottle cap folding and ring cutting machine includes a mounting plate 1, on which a feeding tray 7, a flanging device 2, a conveying tray 5, The ring cutting device 3 and the discharge tray 8 are provided with a driving device 6 at the bottom of the mounting plate 1. The driving device includes a motor (not shown in the figure) and a gear set 6-1. The motor can be connected with any of the gear sets 6-1. One gear connection, in the gear set 6‐1, each gear is connected with the feed plate 7, the edge folding device 2, the transfer plate 5, the ring cutting device 3 and the discharge plate 8, and the gears are meshed and rotated synchronously. When the motor drives When one of the gears rotates, the gear set 6-1 realizes synchronous rotation, so that the feed tray 7, the hemming device 2 transfer tray 5, the ring cutting device 3 and the discharge tray 8 connected to each gear can realize synchronous rotation, Due to the way of gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com