Luggage security check system and method

A baggage security inspection and baggage technology, which is applied in the direction of material analysis using radiation, nuclear radiation exploration, and measuring devices, etc., can solve problems such as increasing the workload of the staff, wrong binding of luggage information, and heavy workload of the staff. Achieve the effects of reducing the time for collecting luggage trays, improving the degree of informatization, and compact structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] The security inspection channel of an airport was intelligently transformed. Originally, there were only luggage X-ray security inspection devices and metal door human body security inspection devices. According to its intelligent transformation needs, a self-service verification channel has been added, and the maximum space for the luggage security inspection conveying channel is only 8 meters.

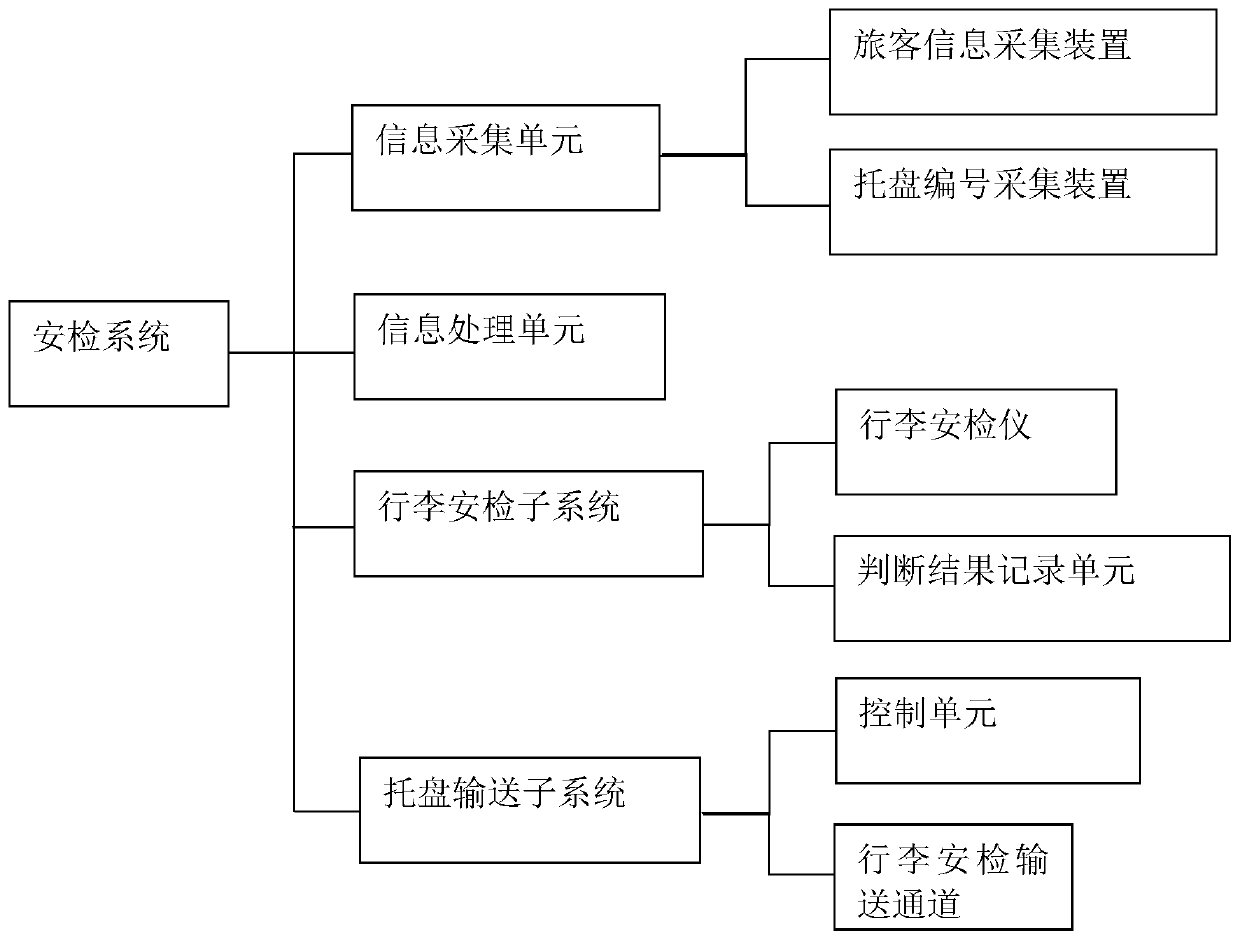

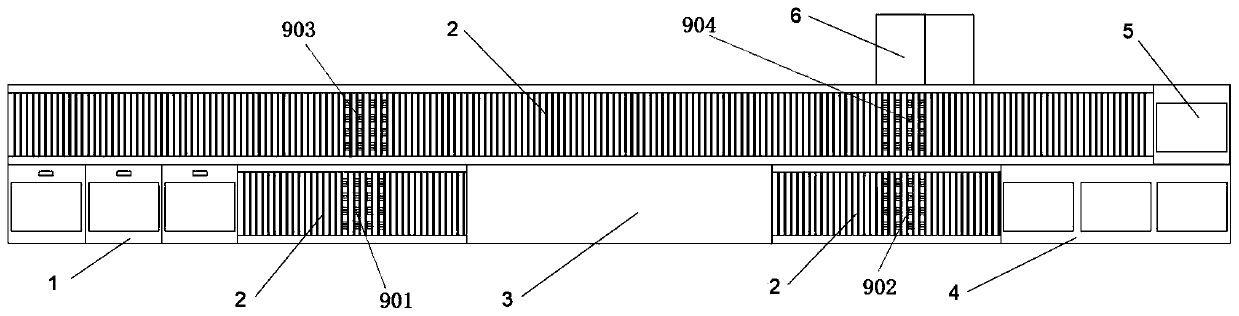

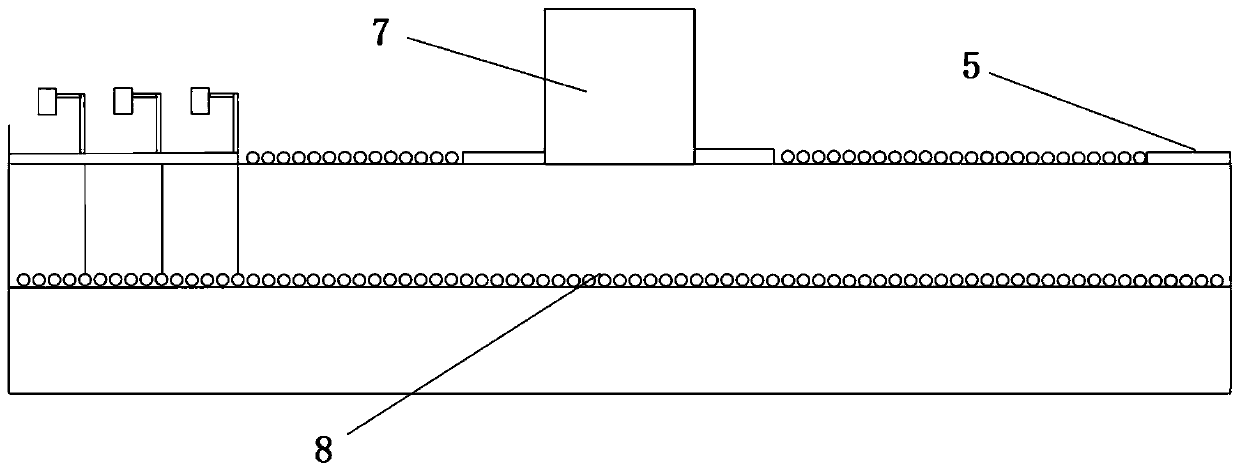

[0135] The baggage security inspection conveying channel applying the present invention has a structure according to figure 2 , image 3 As shown, the baggage security inspection system is composed according to figure 1 shown. In order to solve the problem of limited space, the number of binding tables is set to 2, and on the premise of ensuring complete functions, the luggage conveying roller table is shortened, and the length of the luggage pick-up area is correspondingly shortened, so that the overall length is not more than 8 meters Under this circumstance, the functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com