Automatic filling line of high-purity solvent

An automatic filling and solvent technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of large quality impact, large error, low efficiency, etc., and achieve the effect of convenient procurement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

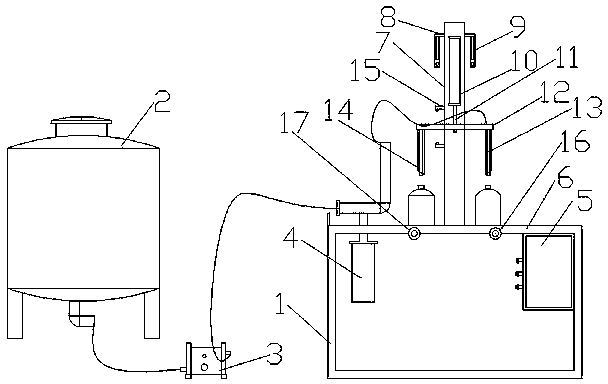

[0019] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

[0020] like figure 1 As shown, a high-purity solvent automatic filling line includes a material tank 2, a material pump 3, an air tank,

[0021] Frame 1, a filling table 6 is arranged on the frame 1, a filter 4 and an air control box 5 are arranged under the filling table 6 in the frame 1, and a vertical pole 7 is provided on the rear side of the frame 1, and the vertical pole 7 The upper end is fixedly provided with two liquid level adjustment gauges 9 through the cross bar 18, and the front side of the vertical rod 7 is provided with a cylinder 10, and the column 7 below the cylinder 10 is fixedly provided with a filling pipe through the cross bar 2 12, and the cylinder 10 and the horizontal Rod 2 12 is connected by telescopic rod 11. The filling pipe includes two feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com