Tubular diffusion furnace temperature area automatic calibration technology based on PID self-setting

A technology of automatic calibration and diffusion process, applied in the field of solar cells, to shorten the calibration time, eliminate human factors, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 The temperature calibration process of a single temperature zone

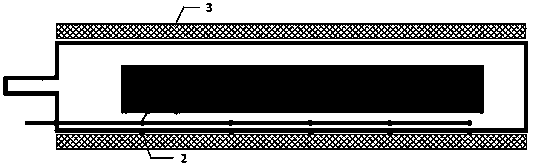

[0045] Such as figure 1 As shown in , the automatic calibration process of the temperature zone of the tubular diffusion furnace based on PID self-tuning provided in this embodiment uses PID technology, and according to the temperature detected by the thermocouple 1 and the temperature control thermocouple 2 on the middle side of the furnace body, the PID technology is used. The temperature inside the tubular diffusion furnace is automatically calibrated to achieve temperature stabilization and automatic compensation of temperature differences in the diffusion process. The schematic diagram of the side thermocouple and temperature control thermocouple in the diffusion furnace is shown in figure 1 As shown in , the side thermocouple 1 is close to the furnace, and the temperature control thermocouple 2 is close to the heating zone 3 of the furnace body, which specifically includes the follow...

Embodiment 2

[0049] Embodiment 2 The temperature calibration process of a single temperature zone

[0050] The automatic calibration process of the temperature zone of the tubular diffusion furnace based on PID self-tuning provided in this embodiment, according to the temperature detected by the thermocouple 1 on the middle side of the furnace body and the temperature control thermocouple 2, uses PID technology to control the temperature in the tubular diffusion furnace. Automatic calibration to achieve temperature stabilization and automatic compensation of temperature differences in the diffusion process, specifically including the following steps:

[0051] (1) Stabilization stage at a temperature of 800°C: raise the temperature to 800°C and keep the temperature constant, feed nitrogen gas with a flow rate of 25000mL / min, keep the temperature constant, and keep the temperature constant for 20 minutes;

[0052] (2) The stage of automatic compensation of temperature difference at a tempe...

Embodiment 3

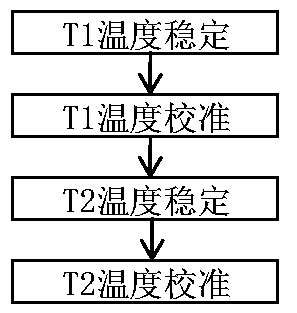

[0053] Embodiment 3 The temperature calibration process of two temperature zones

[0054] Such as figure 2 As shown, the automatic calibration process of the temperature zone of the tubular diffusion furnace based on PID self-tuning provided in this embodiment, according to the temperature detected by the thermocouple 1 on the middle side of the furnace body and the temperature control thermocouple 2, the PID technology is used to control the temperature of the tubular diffusion furnace. The internal temperature is automatically calibrated to realize the temperature stabilization and automatic temperature difference compensation of the diffusion process, which specifically includes the following steps:

[0055] (1) Stable stage at temperature 810°C: raise the temperature to 810°C and keep the temperature constant, feed nitrogen gas with a flow rate of 20,000mL / min, keep the temperature constant, and keep the temperature constant for 15 minutes;

[0056] (2) Automatic compe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com