Intelligent spraying and curing device for concrete surface and control method thereof

A concrete surface and intelligent control system technology, applied in the processing of building materials, construction, building construction, etc., can solve problems such as unguaranteed quality, waste of water sources, and wanton flow of stagnant water, achieving high superiority and convenience, Solve the effect of large randomness and exclusion of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

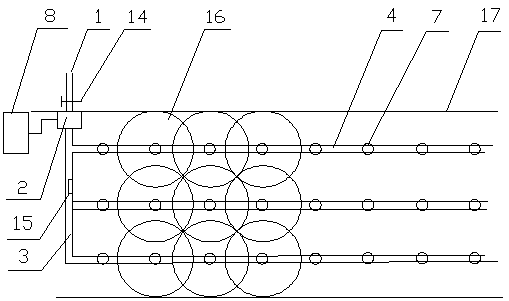

[0024] Take the construction site of XX Wharf as an example: the intelligent spraying maintenance system is used to maintain the cast-in-place surface concrete at the wharf project site.

[0025] The total length of the wharf is 1292m, divided into 19 sections, each section is 68m long, and the width of the wharf is 36m. The width of the rear platform part is 14~22m; the size of the substation platform is 60×17m, and the size of the sailor’s platform is 23×17m; there are 5 approach bridges in total, except for the 6# approach bridge, which is 24m wide, the rest are 16m wide, and the 4# approach bridge is 167.38m long m, 5# approach bridge is 167.89m long, 6# approach ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com