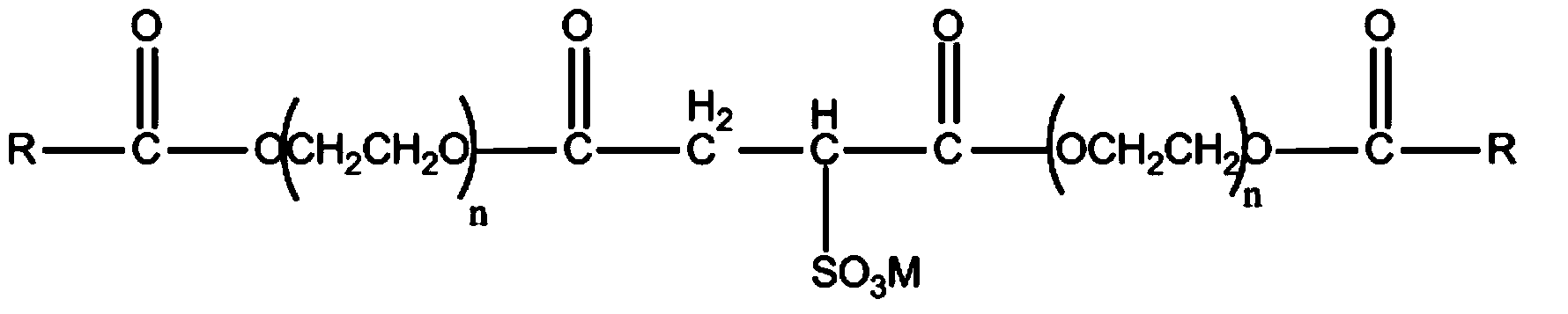

Fatty acid polyoxyethylene succinic acid ester sulfonate, preparation method and application thereof

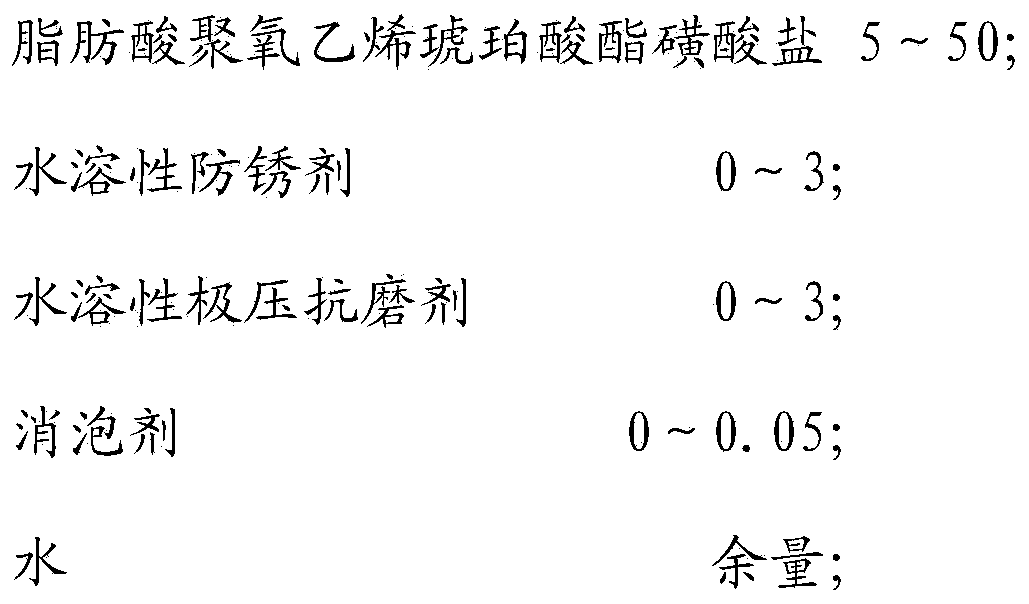

A technology of polyoxyethylene succinic acid and polyoxyethylene ether succinic acid ester, applied in the direction of sulfonate preparation, chemical instruments and methods, transportation and packaging, etc., to achieve better results, reduce environmental and worker hazards, Excellent cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

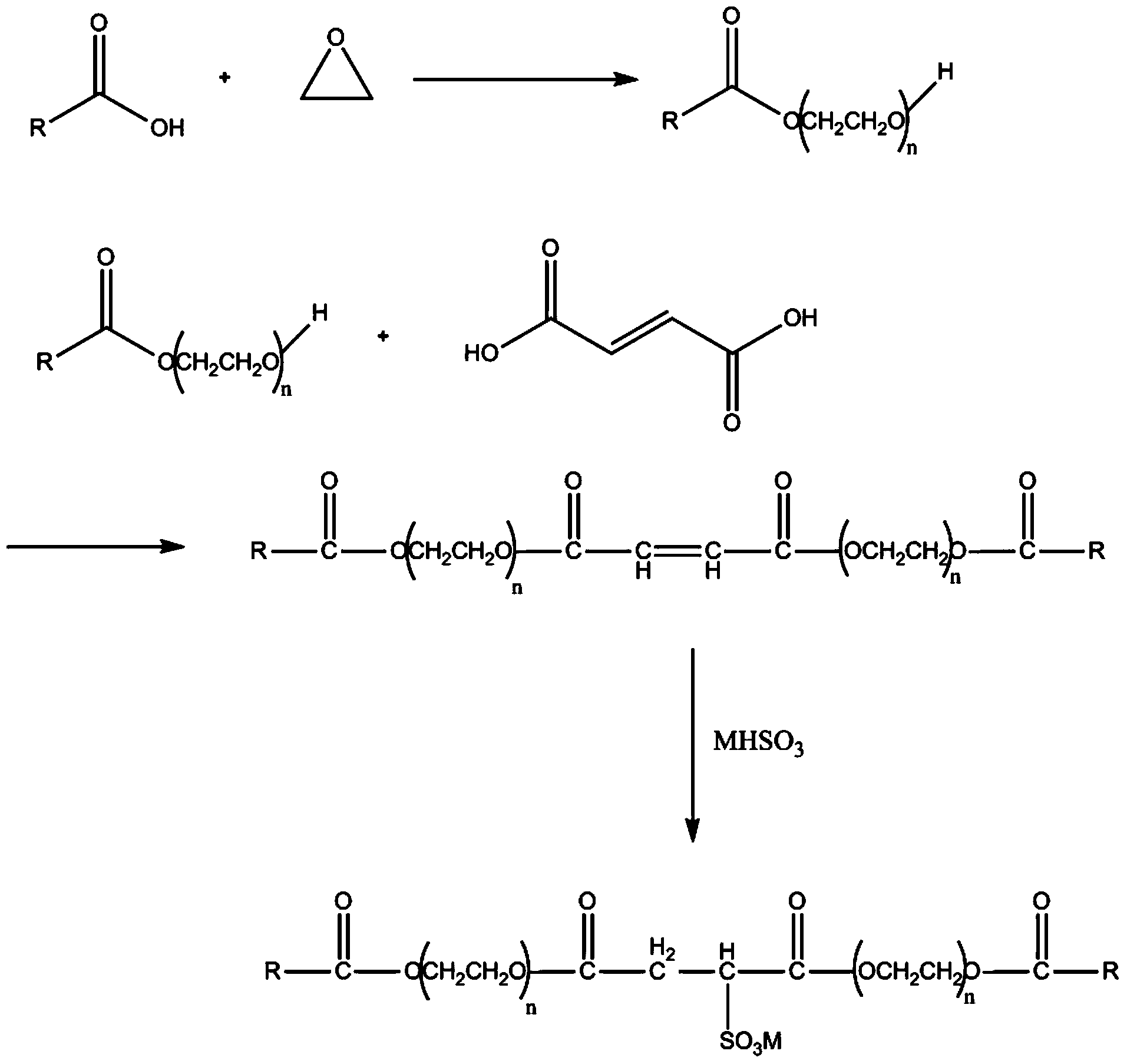

Method used

Image

Examples

Embodiment 1

[0059] Step 1. Put 282.47kg (1000mol) of oleic acid into the polymerization kettle, add 3kg of potassium hydroxide and stir, then feed nitrogen into the polymerization kettle to convert the air in the kettle, and when the nitrogen in the polymerization kettle maintains positive pressure, use nitrogen to Push 440.52 (10000mol) ethylene oxide into the polymerization tank in the material tank, and at the same time stir the temperature to 100°C and adjust the pressure to 0.3MPa. After 3.5 hours of polymerization, use nitrogen to squeeze out the polymer in the polymerization tank, which is oleic acid Polyoxyethylene(10) ether.

[0060] Step 2: Add oleic acid polyoxyethylene (10) ether and 58.04kg (500mol) maleic acid produced in step 1 into the reaction kettle, add 11kg of cation exchange resin, and fill with nitrogen to convert the air in the reaction kettle for reaction , The reaction temperature is: 200°C; the reaction time is: 4 hours; after the reaction, the water is decompres...

Embodiment 2

[0063] Step 1. Put 144.20kg (1000mol) of isooctanoic acid into the polymerization kettle, add 2.4kg of sodium hydroxide to stir, then feed nitrogen into the polymerization kettle to convert the air in the kettle, and when the nitrogen in the polymerization kettle maintains positive pressure, use nitrogen The feeding tank pushes 660.78 (15000mol) ethylene oxide into the polymerization kettle, while stirring and raising the temperature to 90°C, and adjusting the pressure to 0.35MPa. After 5 hours of polymerization, the polymer in the polymerization kettle is extruded with nitrogen gas, which is iso Octanoic acid polyoxyethylene (15) ether.

[0064] Step 2: Add the isooctanoic acid polyoxyethylene (15) ether and 49.03kg (500mol) maleic anhydride produced in step 1 into the reactor, add an aqueous solution containing 3.5kg of concentrated sulfuric acid, and fill with nitrogen to convert the air in the reactor Carry out the reaction, the reaction temperature is: 180°C; the reaction...

Embodiment 3

[0067] Step 1, 284.48kg (1000mol) stearic acid is dropped in the polymerization still, add the potassium hydroxide of 1.2kg and stir, then pass into the air in the nitrogen conversion still in the polymerization kettle, when the nitrogen in the polymerization kettle keeps positive pressure, use The nitrogen feed tank pushes 88.1kg (2000mol) of ethylene oxide into the polymerization kettle, while stirring and raising the temperature to 110°C, and adjusting the pressure to 0.25MPa. After 2 hours of polymerization, the polymer in the polymerization kettle is extruded with nitrogen, that is It is polyoxyethylene stearate (2) ether.

[0068] Step 2: Add the stearic acid polyoxyethylene (2) ether and 58.04kg (500mol) fumaric acid produced in step 1 into the reactor, add 8.6kg of cation exchange resin, and fill with nitrogen to convert the air in the reactor Carry out the reaction, the reaction temperature is 220°C; the reaction time is 3 hours; after the reaction, the water is decom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com