Liquid-crystalline medium, method for the stabilization thereof, and liquid-crystal display

A liquid crystal medium and medium technology, applied in chemical instruments and methods, liquid crystal materials, instruments, etc., can solve problems such as low contrast, insufficient service life, insufficient VHR, etc., and achieve good low temperature stability and low rotational viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0500] Examples 1.1.1 to 1.4.2 and Comparative Examples 1.1.0 to 1.4.0:

[0501] The following host mixture (H-1) was prepared and investigated.

[0502]

[0503] Note: t.b.d.: to be determined.

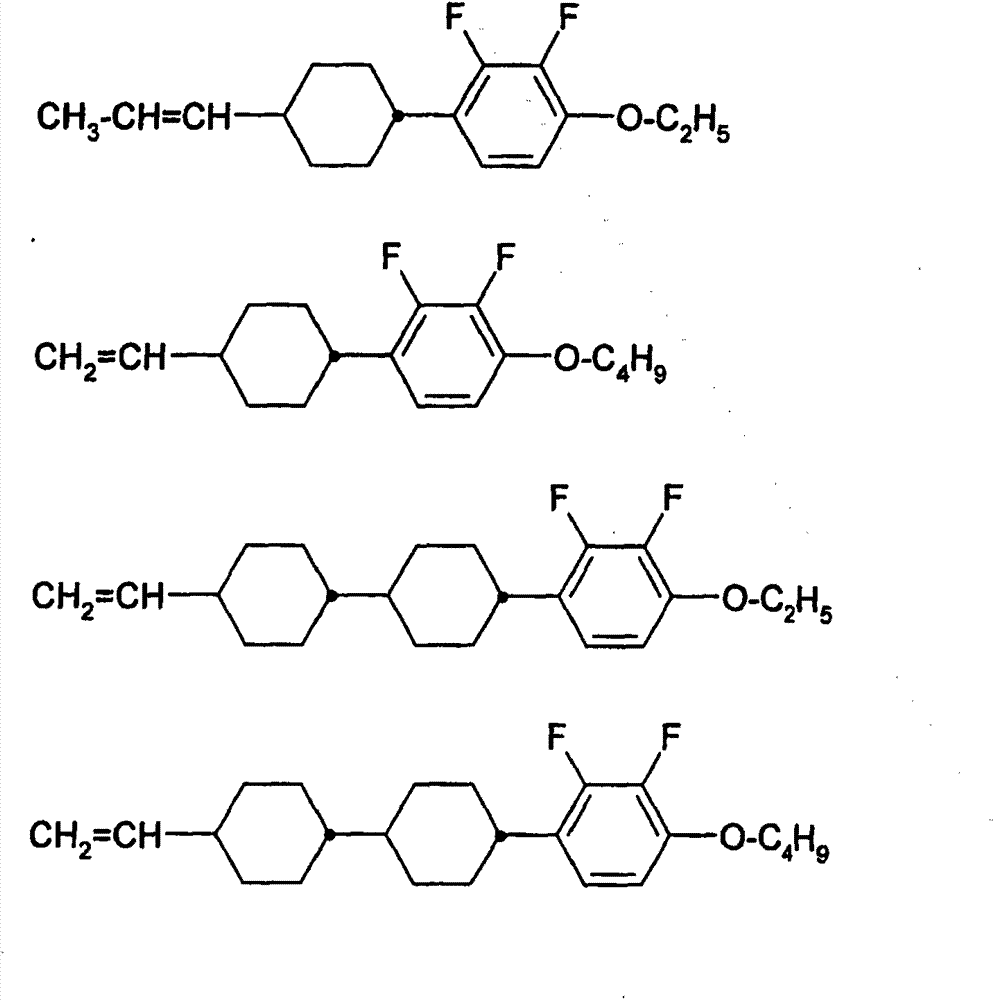

[0504] The mixture H-1 was first divided into four portions. Another compound of formula II was added to each of the quadruples, as indicated in the table below.

[0505]

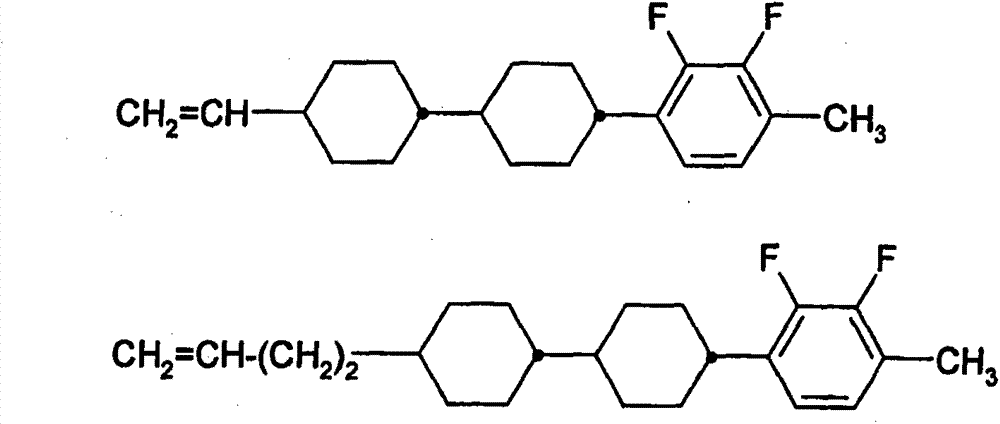

[0506] All these mixtures were then again divided into three portions. The first copy is researched as it is. In addition, 200ppm of the following compound

[0507]

[0508] Or with 200ppm synthesis embodiment 1: the compound of (i.e. material embodiment 1)

[0509]

[0510] Add to the other two portions of the mixture. All mixtures were studied as described below.

[0511] First, the stability of the voltage retention ratio of the mixture (CM-1·n) was measured as it is. Four mixtures (CM-1-n, n ∈ {1; 2; 3; 4}), and four mixtures M-1-n-1, n ∈ {1; 2; 3; 4} containing the compound NOH ) an...

Embodiment 2

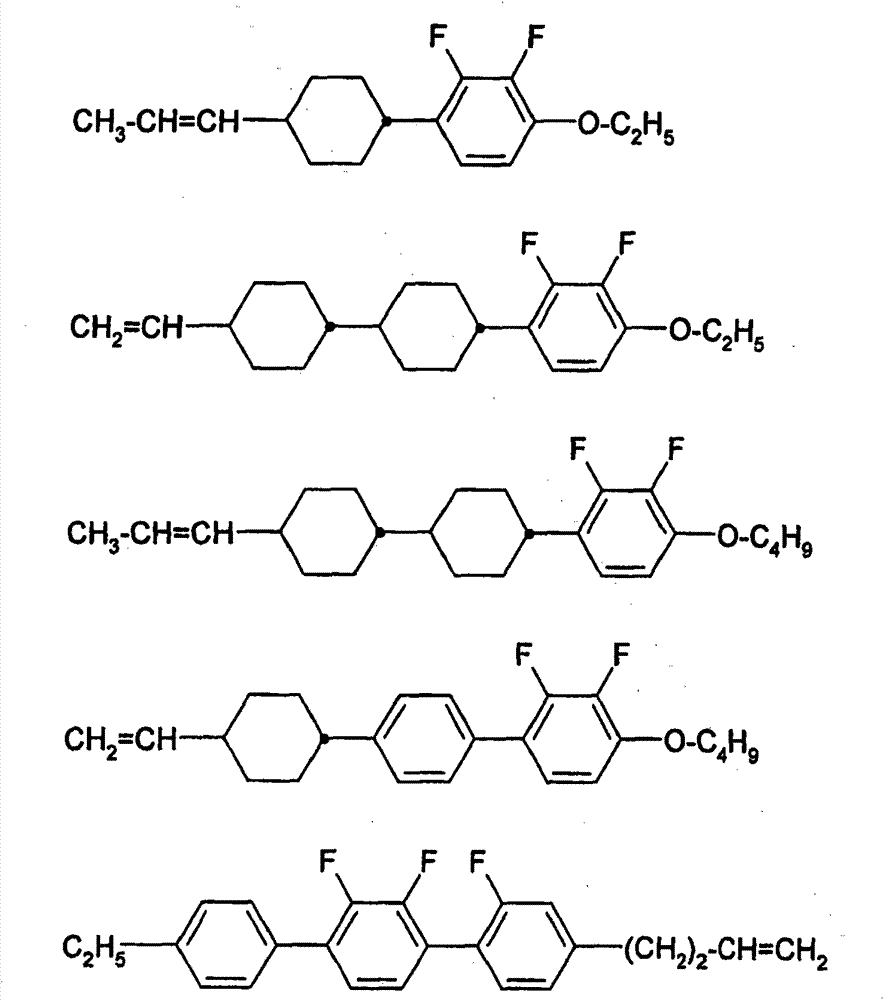

[0521] The following mixture (M-2) comprising 11.5% of the compound of formula II containing an alkenyl end group was prepared and studied.

[0522]

[0523] Mixture M-2 was divided into five portions and studied as described below.

[0524] The first aliquot of mixture M-2, as described in Example 1, was studied without addition of other compounds. In addition, the compound of 100ppm synthesis example 1: (i.e. material example 1)

[0525]

[0526] Or the compound of 50ppm synthetic embodiment 2: (being material embodiment 4)

[0527]

Embodiment 50

[0529]

[0530] or 250ppm compound "NOH"

[0531]

[0532] Added to the other four portions of mixture M-2. The resulting mixtures M-2-1 to M-2-4 were investigated as described in Example 1. The results are shown in the table below.

[0533] Table 2

[0534]

[0535] Note: I(1) * : the compound of Synthesis Example 1

[0536] I(2) * : the compound of Synthesis Example 2

[0537] I(3)*: the compound of Synthesis Example 7

[0538] I(N)*: compound NOH

[0539] All stabilizers used here, especially the compounds of the formula I, significantly improve the stability of the mixtures used. In particular, this applies to values after exposure testing. Stabilizer I (3) here shows a particularly high activity and continues to show a high VHR until backlight irradiation. The use of mixture M-2 in LCDs is only possible to a limited extent without the use of stabilizers. The use of said stabilizers, especially compounds of formula I, leads to an increase in VHR to va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com