Nano-technology of thermal-mechanical composite process for improving fatigue strength of titanium alloy

A fatigue strength and composite process technology, applied in the field of metal processing, can solve the problem of not improving the fatigue strength of titanium alloys, and achieve the effect of improving fatigue strength and expanding engineering applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

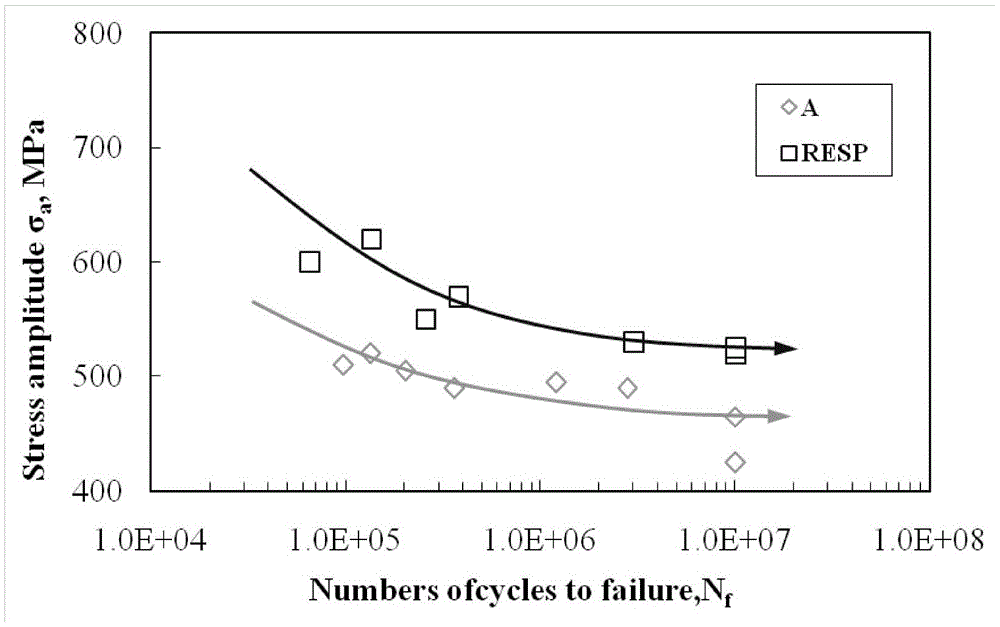

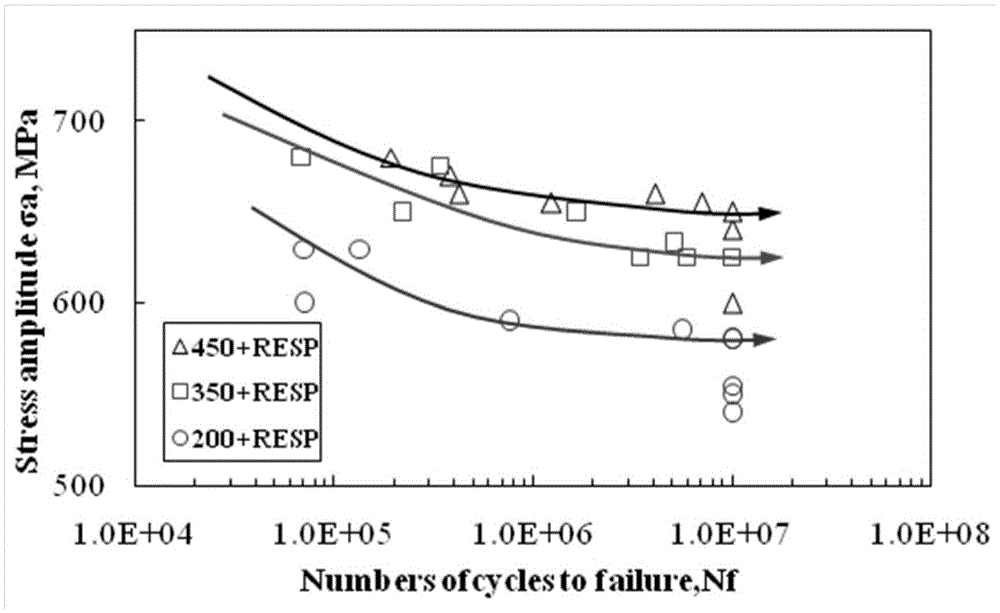

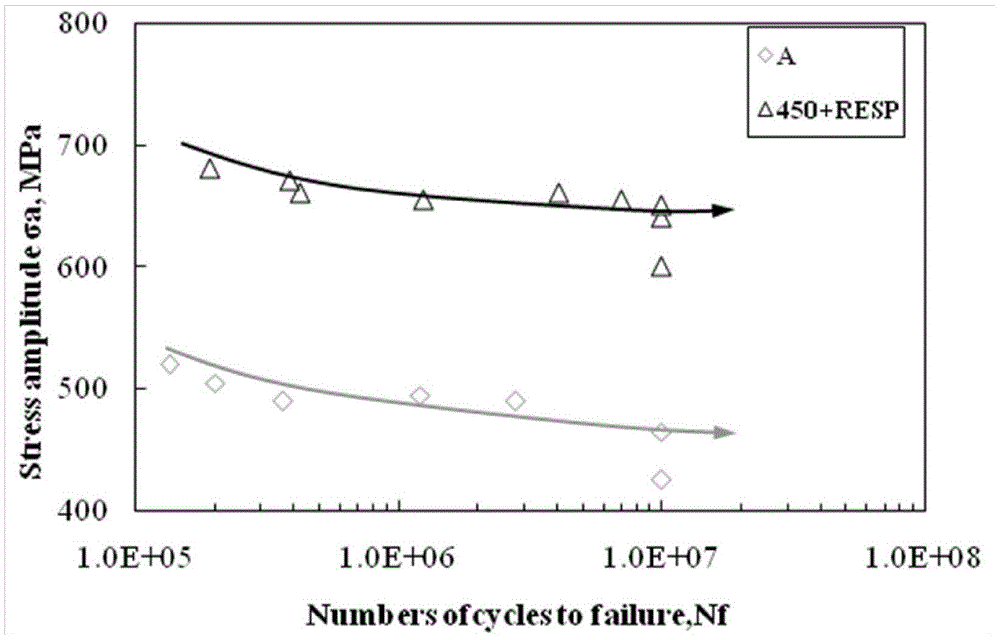

Image

Examples

Embodiment 1

[0034] Example 1: The first shot peening, steel shot diameter 1mm, shot peening time 1 hour, shot peening speed 40 m / s, shot peening distance 400mm; surface damage repair heat treatment temperature 150 ° C, holding time 50min, the second shot Shot treatment, steel shot diameter 0.5mm, shot peening time 20min, shot peening speed 40m / s.

Embodiment 2

[0035] Embodiment 2: The first shot peening, steel shot diameter 1mm, shot peening time 2 hours, shot peening speed 60 m / s, shot peening distance 500mm; surface damage repair heat treatment temperature 300 ° C, holding time 60min, the second shot Shot treatment, steel shot diameter 0.5mm, shot peening time 20min, shot peening speed 60 m / s.

Embodiment 3

[0036] Embodiment 3: The first shot peening, steel shot diameter 1mm, shot peening time 3 hours, shot peening speed 70 m / s, shot peening distance 600mm; surface damage repair heat treatment temperature 450 ° C, holding time 70min, the second shot Shot treatment, steel shot diameter 0.5mm, shot peening time 20min, shot peening speed 70m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| fatigue limit | aaaaa | aaaaa |

| fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com