Device for eliminating movement of bridge end track ballast of large-span bridge with ballast tracks

A technology for long-span bridges and tracks, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as difficulty in maintaining the geometric shape of the rail telescopic adjuster, difficulty in maintaining the geometric shape of the adjuster, troublesome maintenance and repair of the public works department, etc. Achieve the effect of reducing maintenance and repair workload, simple structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

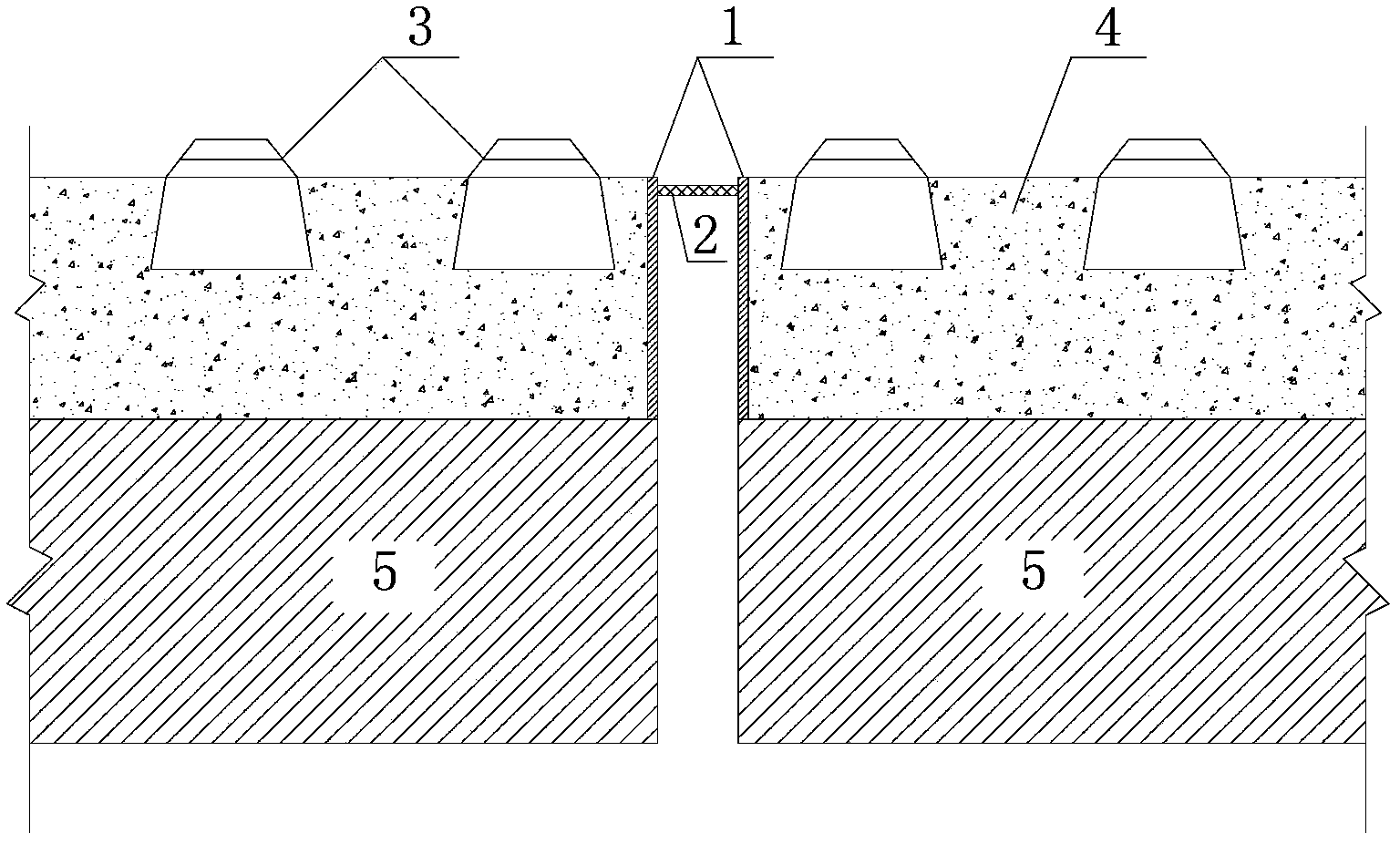

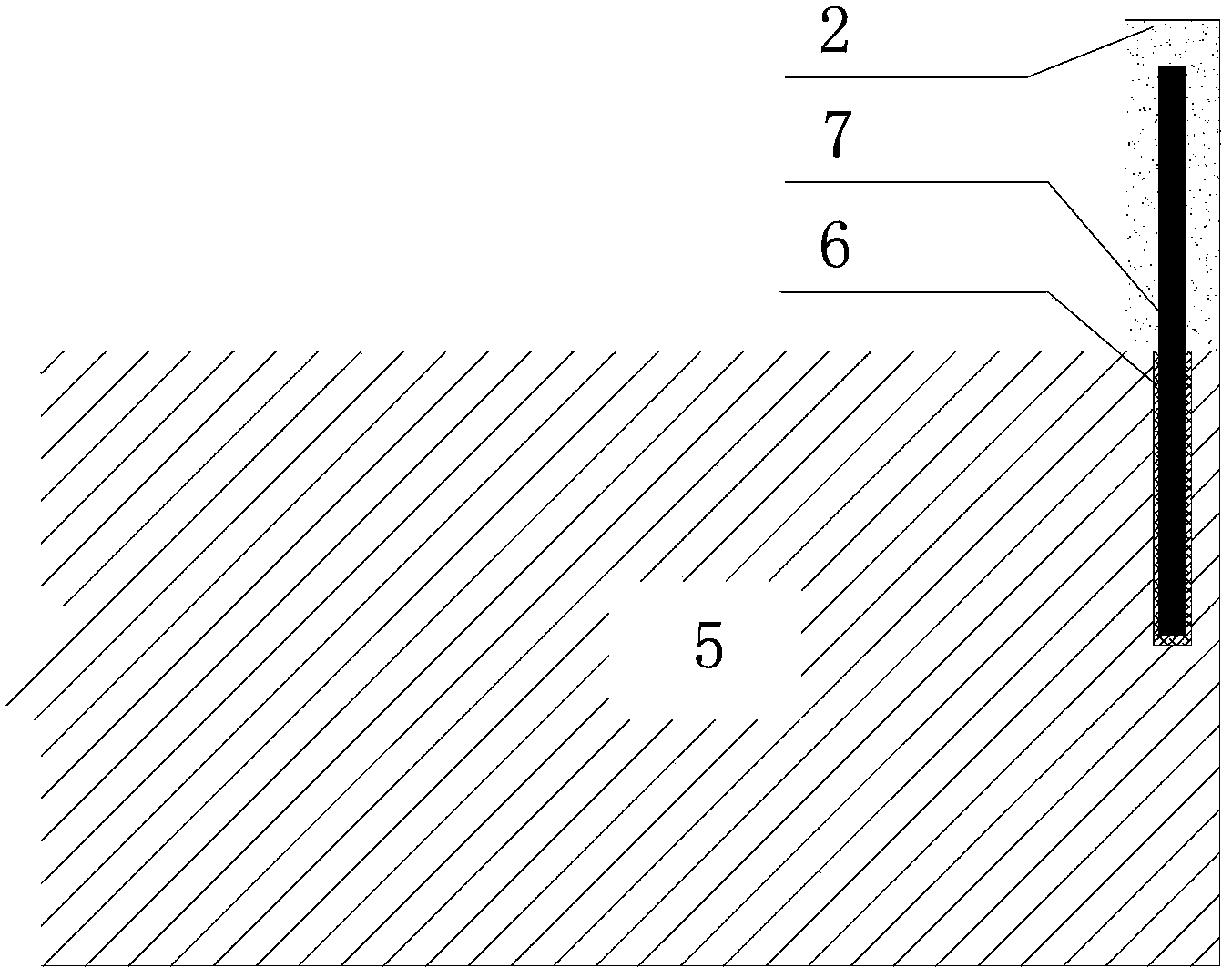

[0017] Such as figure 1 , figure 2 As shown, a device for solving ballast movement at the end of a long-span bridge with ballast track, it includes a ballast 4 arranged on a bridge girder body 5, a railway track 3 is arranged on the ballast 4, and along the railway track 3 The side of the ballast 4 on the bridge beam body 5 is provided with a ballast retaining plate 1. In this embodiment, the bridge beam body 5 is a concrete structure, and the ballast retaining plate 1 is a reinforced concrete structure. 6 and steel bars 7 are combined with the bridge girder body 5 as an integrated structure. An anti-fall structure 2 is provided between adjacent ballast retaining plates 1. The anti-fall structure 2 can expand and contract freel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com