High-speed rail bridge wind shielding structure vertical column

A high-speed railway and column technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of easy overturning, stiffness, stress, and connection reliability that cannot meet the requirements of high-speed railways, and achieve the purpose of increasing the bending arm , construction difficulty and workload reduction, and the effect of solving fatigue problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in combination with specific embodiments.

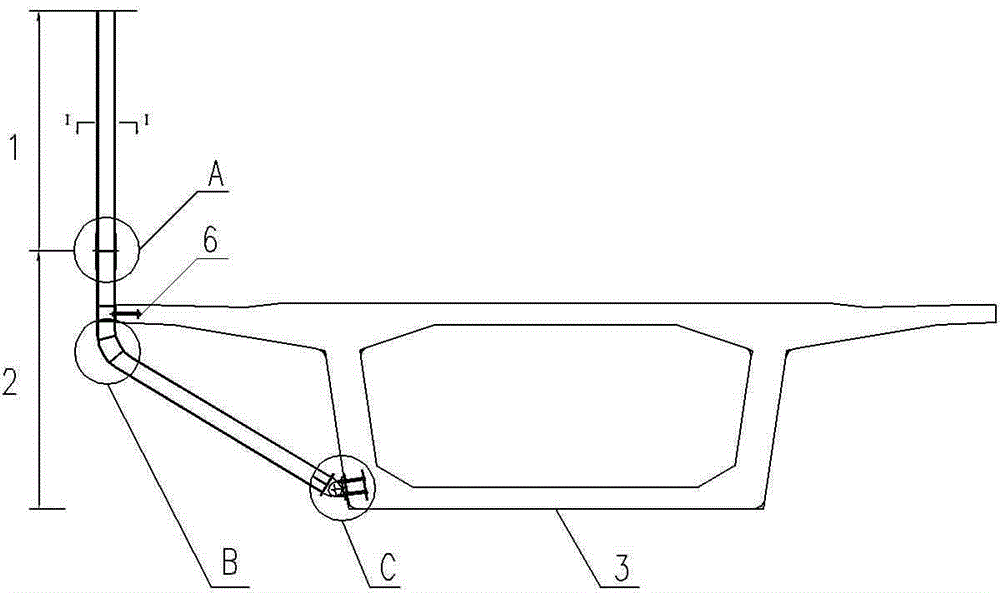

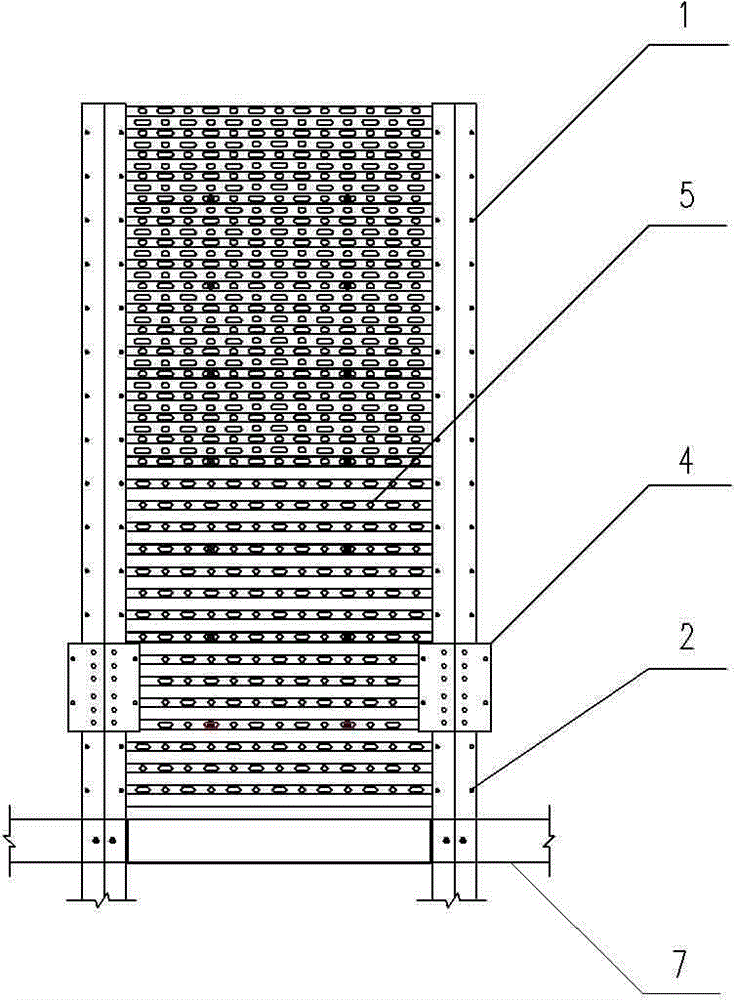

[0033] The invention relates to a column of a high-speed railway bridge windshield structure, which is installed on the windward side of the bridge girder, and is arranged on one or both sides along the longitudinal line, with a longitudinal distance of 1.6-2.5m, and a windshield with holes is fixed between adjacent columns , forming a windshield structure.

[0034] Controlled by the train limit, the column above the bridge deck adopts a straight line form, called the straight section column 1, and below the bridge deck, according to the cantilever length of the beam body flange and the anchorage position of the web, it is set in the form of a local arc L-shaped column, called the bent section column 2. The straight column 1 and the curved column 2 are spliced up and down and fixed. The straight column 1 is a rolled H-shaped steel, and the curved column 2 is a welded a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com