Method for renovating open-joint grouting damage of CRTS I-type double-block ballastless track sleeper

A ballastless track, double-block technology, used in tracks, track laying, track maintenance, etc., can solve the problem of tightness between sleepers and concrete ballast beds, which has not been fundamentally solved, and the vibration frequency of double-block sleepers and ballast slabs is inconsistent and damaged. Double-block sleepers around the track bed slab concrete and other problems can reduce the maintenance workload, improve the remediation effect, and facilitate the construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

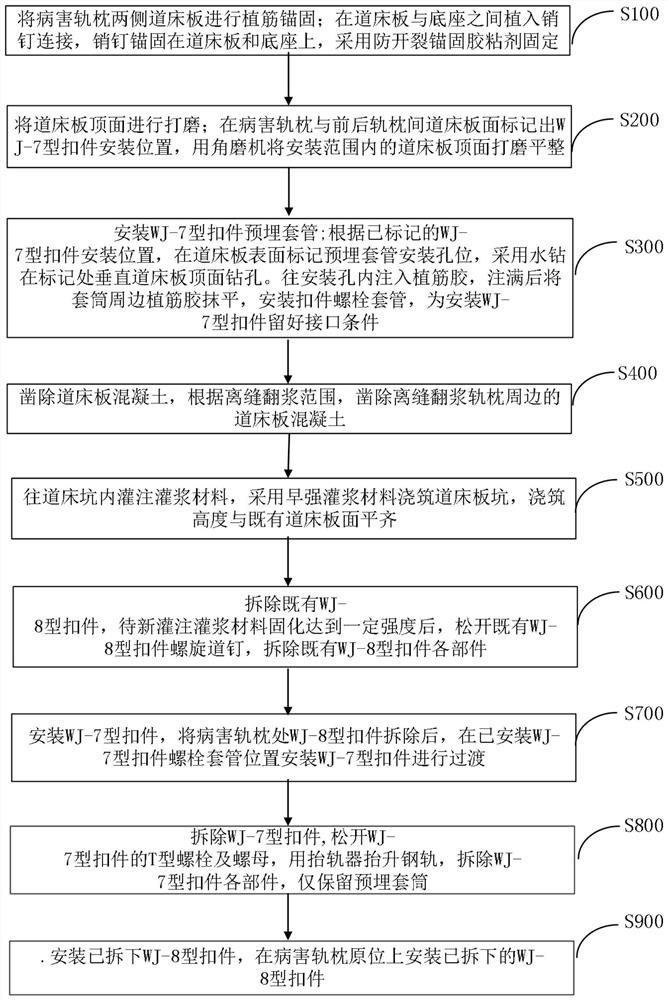

[0037] A treatment method for the defect of CRTS type I double-block ballastless track sleeper from the separation joint, such as figure 1 ,include:

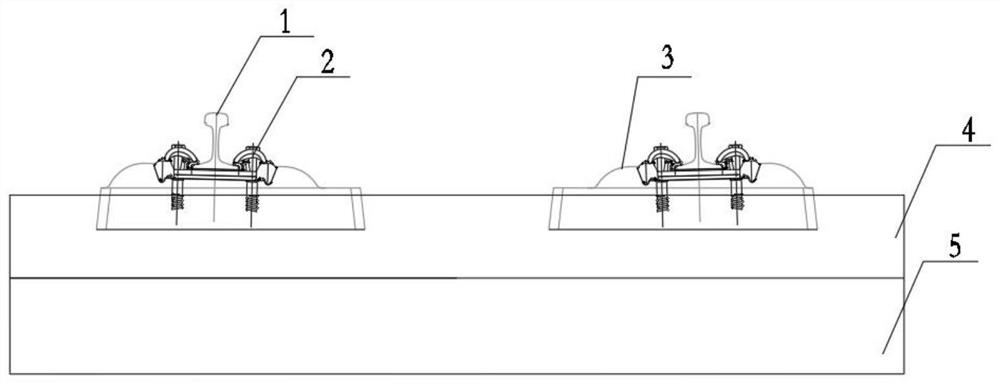

[0038] S100. Plant reinforcement and anchor the track bed boards 4 on both sides of the diseased sleeper 9; implant pin connections between the track bed boards 4 and the base 5, and the pins are anchored on the track bed boards 4 and the base 5, and fix them with an anti-cracking anchoring adhesive.

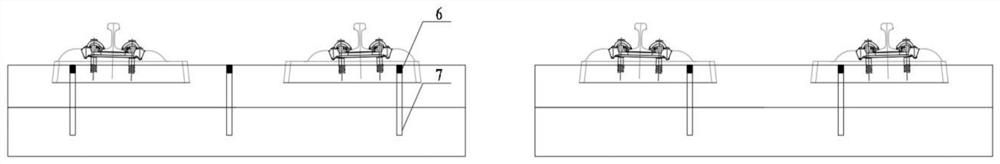

[0039] Specifically, such as figure 2 , 3 4. Carry out reinforcement anchoring with the track bed plates 4 on both sides of the diseased sleeper 9, and connect the φ28 pins 7 with a length of 440mm between the track bed plates 4 and the base 5, wherein the length implanted in the base 5 is 220mm, and the track bed plates 4 The inner length is 220mm. The pins 7 are generally arranged in the form of 3+2, with 3 or 2 pins planted in each row. The pin 7 is anchored on the track bed slab 4 and the base 5 in the form of reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com