A method for recording drilling depth and hammering times and drilling device

A technology of drilling and depth, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc. It can solve the problems of inaccurate hammering number, inaccurate judgment of underground geology, and failure to reach, etc., and achieves easy to grasp, weight Lightweight and easy to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

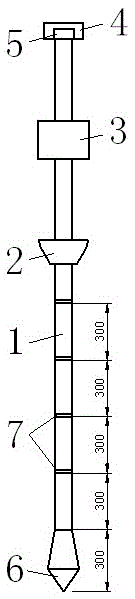

[0014] A method of recording the depth of drilling and the number of hammer blows, such as figure 1 As shown, the method is to install a hammer sensor 2 on the drill rod 1, and the hammer 3 hits the hammer sensor 2 once, and the counter 4 located at the top of the drill rod just records once; a group of infrared rays are installed at intervals on the drill rod 1 Transmitter 7, when the probe 6 at the bottom of the drill rod 1 enters the ground to reach a depth of interval under the hammer 3, the infrared alarm 5 that is located at the top of the drill rod 1 immediately fails to receive the signal of the infrared emitter 7. Alarm, judge the depth of the probe 6 entering the ground by the alarm sound. The group of infrared emitters 7 is installed between the probe 6 and the impact sensor 2, one at an interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com