Fast safe solid expandable tube reinforcement device for oilfields

A reinforcement device and expansion tube technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve problems such as overhaul well scrapping, reinforcement subsidy failure, expansion cone damage, etc., to improve the efficiency of casing repair work, significantly economical Benefits, the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

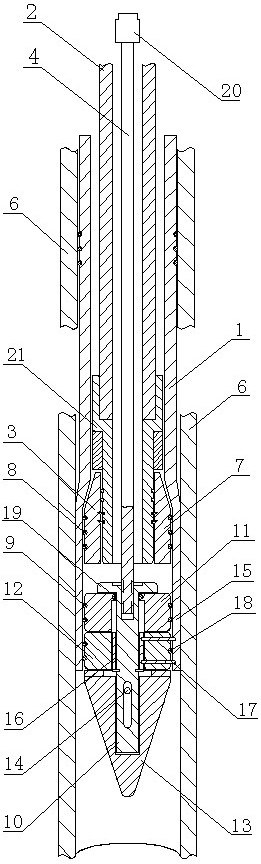

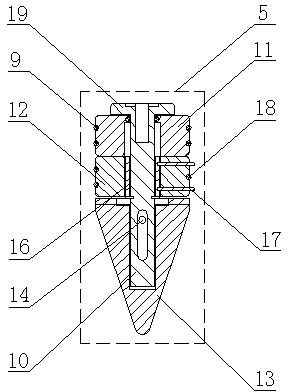

[0015] The fast and safe solid expansion pipe reinforcement device for oil field of the present invention is composed of expansion subsidy pipe 1, hydraulic pipe 2, expansion cone 3, lifting rod 4 and combined bottom plug 5, and is an expansion subsidy that fits in a gap in the damaged oil well casing 6 An expander is placed in the tube 1; the expander includes: the lower end of the hydraulic tube 2 is connected to the upper port of the quick insertion rod 21, and the lower end of the quick insertion rod 21 is embedded in the expansion cone 3, and the cylinder 7 of the expansion cone 3 is connected to the expansion chamber 15. The inner wall is tightly fitted, and there is a sealing ring 8 around the cylinder 7, and the upper part of the cylinder 7 is conical, and the lifting rod 4 passes through the hydraulic pipe 2, the quick insertion rod 21, the expansion cone 3, and its lower end through a clearance fit from top to bottom. It is tightly connected with the combined bottom p...

Embodiment 2

[0017] The fast and safe solid expansion pipe reinforcement device for oil field of the present invention is composed of expansion subsidy pipe 1, hydraulic pipe 2, expansion cone 3, lifting rod 4 and combined bottom plug 5, and is an expansion subsidy that fits in a gap in the damaged oil well casing 6 An expander is placed in the tube 1; the expander includes: the lower end of the hydraulic tube 2 is connected to the upper port of the quick insertion rod 21, and the lower end of the quick insertion rod 21 is embedded in the expansion cone 3, and the cylinder 7 of the expansion cone 3 is connected to the expansion chamber 15. The inner wall is tightly fitted, and there is a sealing ring 8 around the cylinder 7, and the upper part of the cylinder 7 is conical, and the lifting rod 4 passes through the hydraulic pipe 2, the quick insertion rod 21, the expansion cone 3, and the lifting rod 4 from top to bottom. The lower end of 4 is tightly connected with combined bottom plug 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com